I will be honest at first i was upset to see you start to paint the wheels bumpers etc black. Just because you very rarely see a 700+ hp truck that looks bone stock on the outside, but i must say you did it right and still looks very classy. After seeing some of your bad luck with these im glad to see you finally got a good runnning bad ass truck. Congrats !

Agreed. A lot of folks wanted to see me leave it completely stock looking.

I'm a Huge fan of "Sleepers" also, hence the reason the "Interceptor" stayed so stock looking.

The main reason I did the black out was because I'm such a Huge Silver fan that this Khaki really didn't interest me that much in the beginning. I almost refused to buy it soley on the color. And to be honest, wouldn't have bought it if it wasn't such a good deal.

But I started to look at pics on CF in the "Khaki Trucks" thread... The blacked out look really started growing on me. I REALLY like it now. I still think it sorta "Sleeperish" still. The black brought out the color a lot more.

But the Coolest part is with the Plasti Dip and the fact that I saved the stock Chrome Clad Alum. wheels, I can put it Right Back to the stock look in half a day.

Yes, my luck was not good with my 05. It was a real shame too because I did Love that truck and it ran Really Really well for short periods. I've very thankful to have this second chance though and I'm enjoying it. The Drive to go quicker and quicker with more power / lock up switch is still in me though... It's killing me to just leave it alone, but I know it's best for me right now.

Thanks man!!

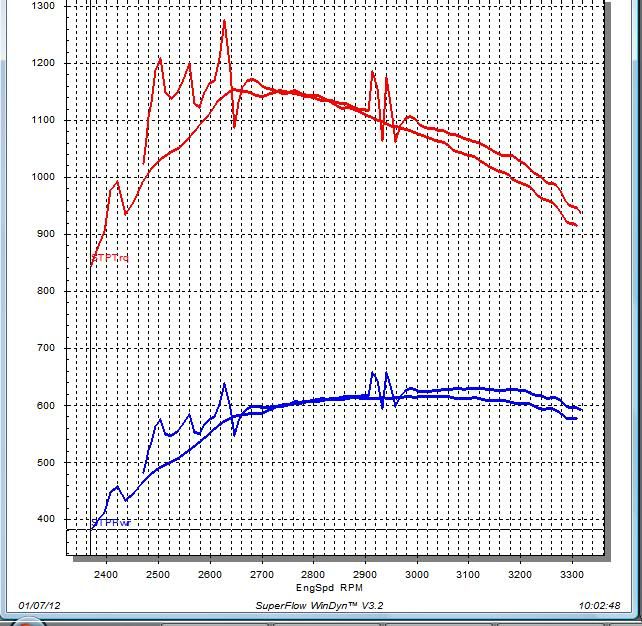

I've often wondered if high primary boost numbers could be related to the secondary charger not being able to move the air from the primary through the intercooler and into the engine causing the cold pipe to become a pressure vessel instead of a transfer pipe. Seems like something that could happen. My secondary is similar to yours in that the compressor is large for the size of the turbine. Seems like turbo's that are prone to surge as a single sometimes work well in compounds.

This turbo "Map, sizing, Tuning, etc" thing is still way over my head. I've just not made myself try to learn and retain what I should about them. But for the most part, playing with it like this is teaching me a bit...I'll keep trying to get it right.

Thank you Sir!!

Yeah, I'm not sure where the 50-50 thing came from but personally I make the most power working the primary as hard as I can. Bottom end though you want that gate locked down good.

I think it can be set up decent with a spring on the gate, but I gave up on that and went to a diaphragm pot actuator that references primary pressure.

The spring gate might be quicker on shifts though if your rpm's get low enough that you need to be into the secondary. I didn't find that to be a problem though 64/480.

Very Interesting Chris!

I'm not sure on the 50/50 thing either. It's just what I've always heard and was told my Nathan at MPI about the kit that I bought from him for the "Interceptor". I think it may be More for keeping Drive Pressures in check than for make perfect HP for the setup.

I will try to do some with and without it completely clamped test going back to back runs in the 1/4....May be a week or so though. Gotta work the next 8 days in a row...

Thank you for the Info Sir!