The bridges rocker system is horrible,

I’m more than likely the only person around that has been on a spintron with a 4 valve Cummins. The bridges wobble all over the place. The lift can vary up to .015 , from side to side . This even truer with the 4.6 Ford single springs, that the other guy sells for so cheap. I will not sell a single spring for this reason

The dual springs I designed and sell, helps a lot, in that the variance is less than .003. The dual springs are more progressive, and mantain equal pressure thru the lift range.

The misunderstood part of rockers on a diesel is that they are for friction reduction, there is a small percentage gains in power in friction reduction at the rpms we are running.

The only gain is to use high ratio rockers. The 4 valve Cummins needs lift in the .600 + range on fully ported head, and the Dmax is very similar. The 2 valve Cummins head is happy at .850+ lift.

to know this, you must have , and use one of these below

To get those lift numbers you will need big ratios. I have 2.25 to 1 rockers for 12 valves in final testing, and going in to production. The 4 valve rockers are 1.95 to 1 .

The other aspect is that the diesel power cycle, wants very short timing events, so to stay within the parameters you must reduce lift / base circle. To do this you either make a bigger cam core, as in my 60 mm Cummins core up from the stock 54.5 mm stock cores, or increase rocker ratio. Or do both.

Here is so preproduction pictures of the rockers for a Cummins CR / 24 valve, the productions parts will have cast bases. These are over $3700, but well worth it if you going to build a ultra competitive program.

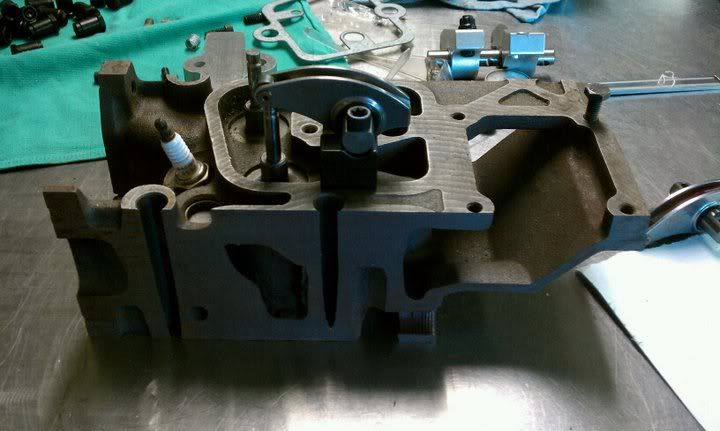

Here is also so of the early development of the 12 valve rockers, they have come a long way since this old pictures

here is a 60mm billet core next to a stock 54.5 core