You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Swole...Again!

- Thread starter jordanjames81

- Start date

jordanjames81

New member

- Joined

- Jan 8, 2009

- Messages

- 3,411

Swole when you going to start taking it down?

Sticky

Megaslab

- Joined

- Jul 26, 2008

- Messages

- 1,531

Someone should start a poll and rename the interceptor......my vote is on DEVASTATOR:rockwoot::lolly:

COW was a good one as welloke:

love it:rockwoot:

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

Rename it b*tch because it's almost as expensive and troublesome.

LOL

Thats the dang truth!!

Swole when you going to start taking it down?

Hoping to take it down there tmrw. but it'll have to set until they get another build out of that Bay...

Jeff's gonna have Sticky and Stan start on it for me even If I can't get down there that much.. He's awesome to do this !!

Just as soon as I have info to post and pics, I sure will !!

Someone should start a poll and rename the interceptor......my vote is on DEVASTATOR:rockwoot::lolly:

COW was a good one as welloke:

Devastation cow or cow of Devastation I do like the idea of using devastator.

I really hope this all comes out good for you David.:Cheer:

We will check it for sure this go round..

I guess Eric at Mahle can shed some light on what they should be.. Or anyone else have a clue on a std. size monotherm ??

BTW, I've never had to messure / change ring gaps... How is this accomplished? Esp. the changing part...How / What is used to take material off to widen the gap a bit, if it's too tight?

Good examples and explanations on how to set ring gaps were posted. I believe Cummins specs the top ring @ .038-.042 and the bottom @ .028-.032. This is off the top of my head so don't take this for granted...I don't have my manuals in front of me. Also...for the monotherms it will vary because of expansion due to heat. It should be pretty close to stock...I could also be talking CHIT since I have never installed a set.

Ring gaps also vary due to power being made, charger pressures, and even nitrous applications all have there ring gap requirements.

Rob, you are So right on the "Friendships" thing...

This truck has caused me so real big pains but in turn it has also made me SO Many friends and contacts, Like yourself... I love the fact that I know so many folks because of it and even though I've never met most of them in person, I still feel very close to them and Appreciate their Friendship Big Time!!

It would be nice to finally have a program that runs for a long while, but the learning is great too!

And, YES building these things 3 & 4 times now is Very exhausting!!

I feel your pain on things not working. It has happened to me many times in my own projects (just ask those people when a transmission could not hold more than 400 hp)! The people you meet in this community...at least the folks that have been in this game for 10 plus years are all top notch including some of the newer ones. The help you have received has been not only for you but for them. It is the experience in anything that we do that makes up better, and diagnosing the problem is were we all win. I have no doubt that your truck will be done properly by the people working on it. They have all been stand up and NO amount of money can speak up for that.

Last edited:

No, thank you!!! Im glad we got a chance to talk because now Im sold on Garmon. Maybe one day I will have Jeff build me a motor. Im really tossing the idea of it around. I guess the only thing I will need from him is a price. Im stoked to get this trans, I feel like a little kid waiting for Christmas. This sucks, I hate anticipation and waiting.

Im really hoping this is going to be an easy fix for you.

Im really hoping this is going to be an easy fix for you.

Joesixpack

Pull'n it.

- Joined

- Apr 4, 2008

- Messages

- 4,118

EEK...no checky ring gap.....thats just one of those things. No use relying on some Mexican packaging at less than minimum wage to get it right

The rings that Mahle supplied me gapped a bit wide, .030 on top about double second ring. So that will blowby a little more than stock but not bad.

Not to stir the chit as I don't owe any supplier squat, but those nozzles were sac nozzles right? Were they the ovate holes that got 20 mins of hype a while back?

Got a cult following! LOL Your threads are usually educational one way or the other.

One edit....still don't think this was assembly, that fuel lighting off early breaks chit, you know the noise I'm talking about when the nozzle took a dump.

The rings that Mahle supplied me gapped a bit wide, .030 on top about double second ring. So that will blowby a little more than stock but not bad.

Not to stir the chit as I don't owe any supplier squat, but those nozzles were sac nozzles right? Were they the ovate holes that got 20 mins of hype a while back?

Got a cult following! LOL Your threads are usually educational one way or the other.

One edit....still don't think this was assembly, that fuel lighting off early breaks chit, you know the noise I'm talking about when the nozzle took a dump.

Last edited:

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

EEK...no checky ring gap.....thats just one of those things. No use relying on some Mexican packaging at less than minimum wage to get it right

The rings that Mahle supplied me gapped a bit wide, .030 on top about double second ring. So that will blowby a little more than stock but not bad.

Not to stir the chit as I don't owe any supplier squat, but those nozzles were sac nozzles right? Were they the ovate holes that got 20 mins of hype a while back?

Got a cult following! LOL Your threads are usually educational one way or the other.

One edit....still don't think this was assembly, that fuel lighting off early breaks chit, you know the noise I'm talking about when the nozzle took a dump.

I will make sure to check it this time, no matter what!

Just need to make sure I get all my measurements to give Eric and then get the proper gaps recommended..

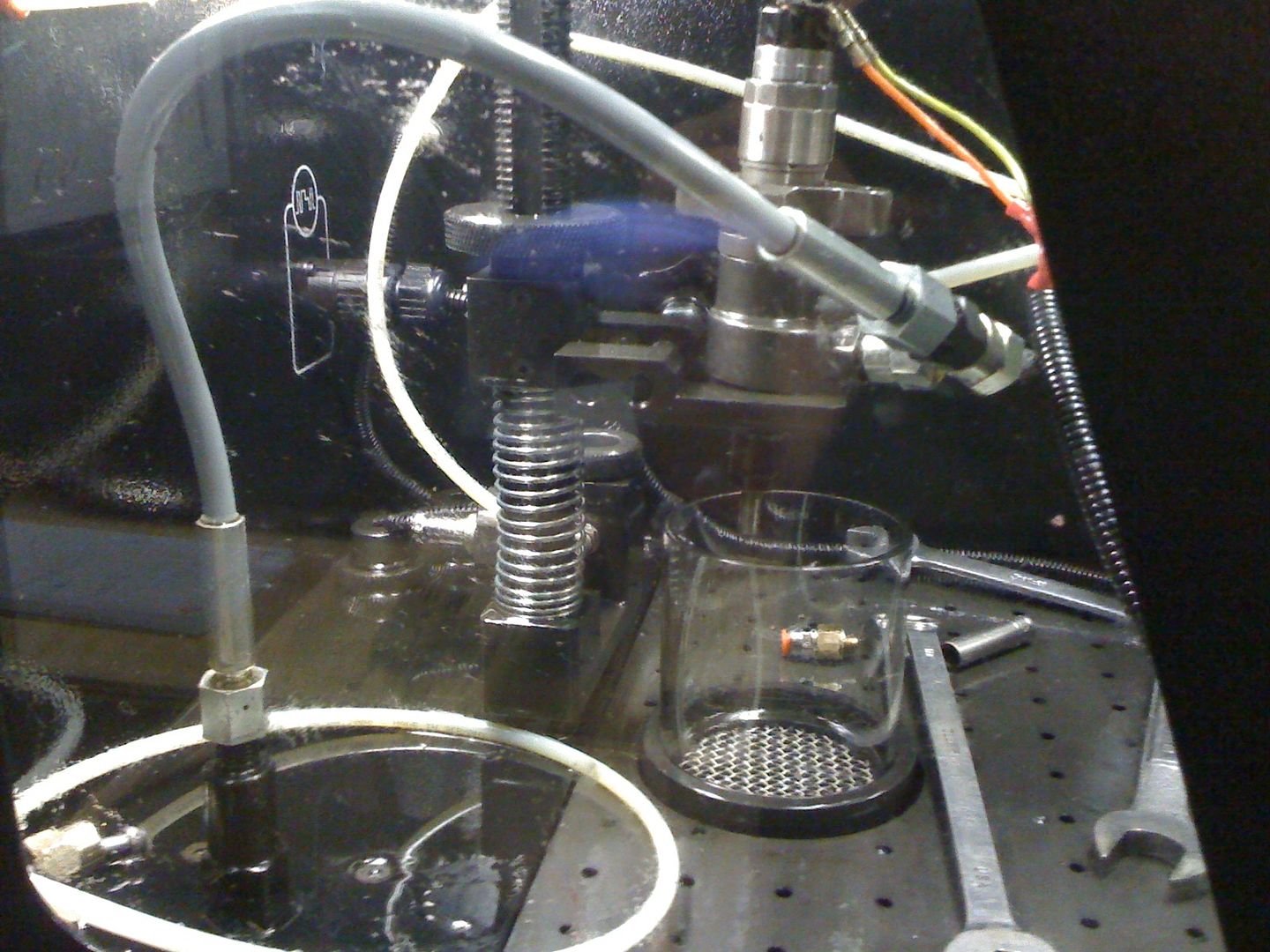

Here is the old tips... I think they are called SAC style...

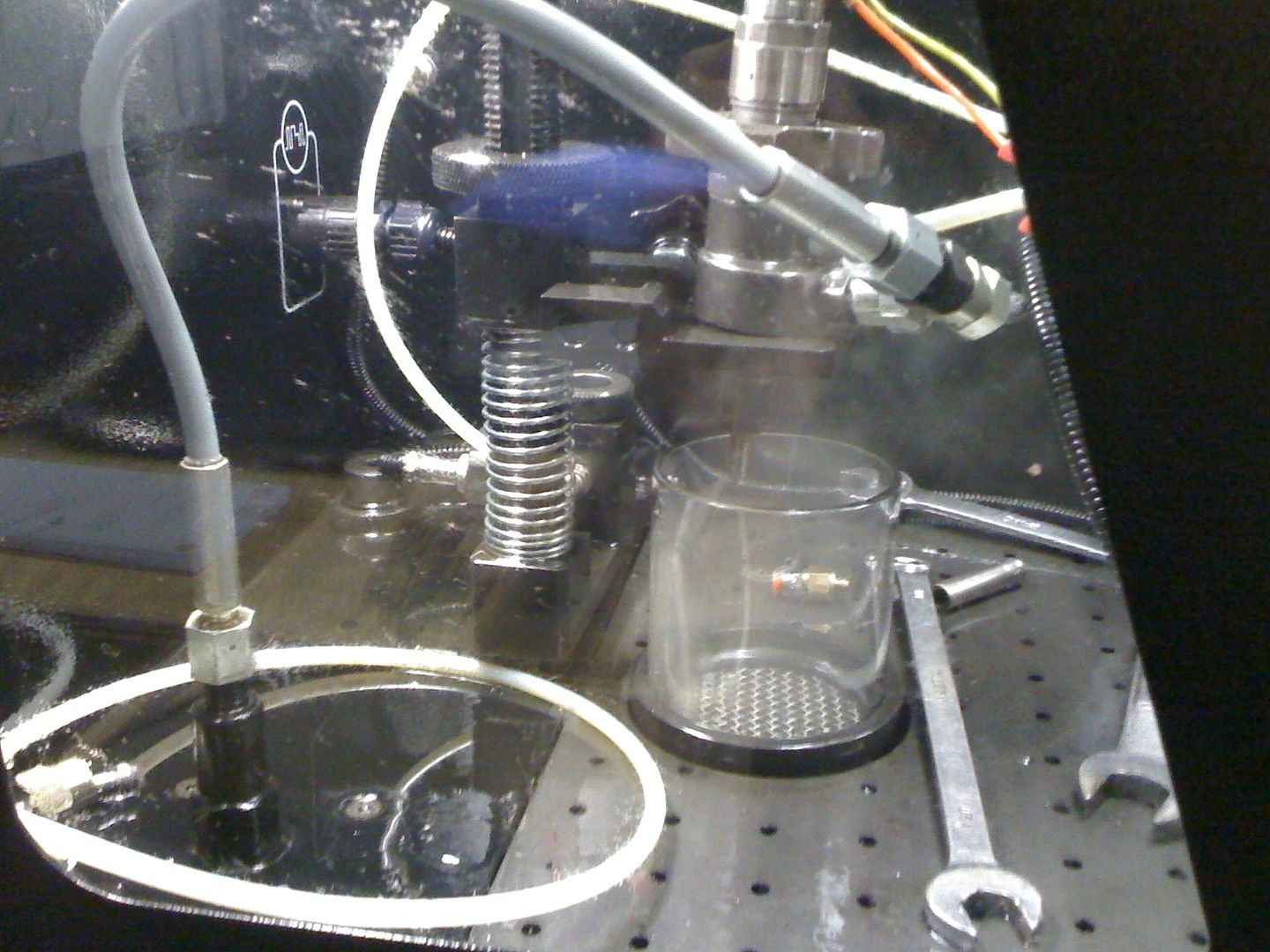

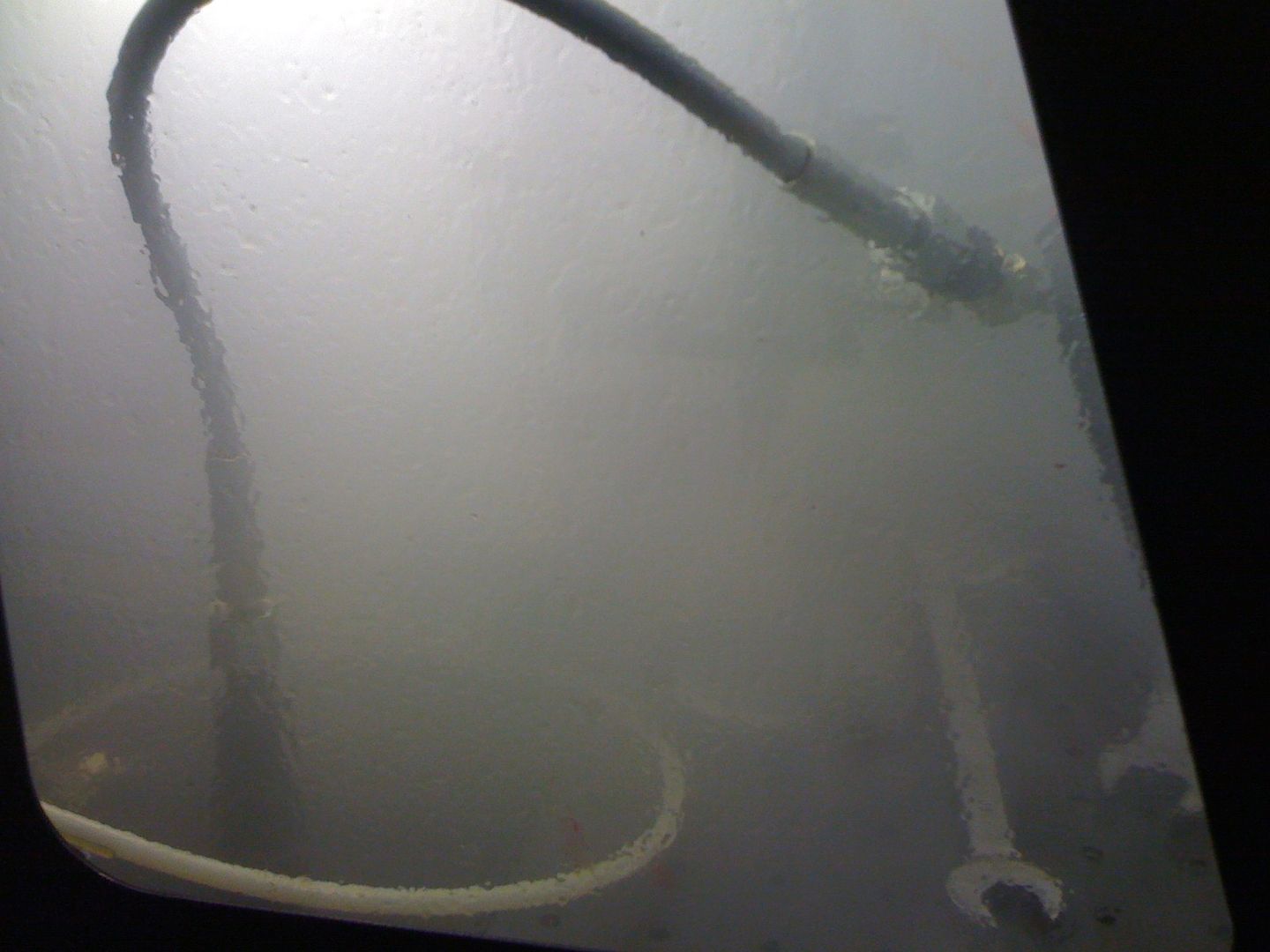

Here is the pic of the split tip being run on Jeff's injector machine....Can you see the HUGE amount of fuel spraying out the side??? It's hitting the side of that Glass thing inside the chamber..

It wouldn't even let the machine pump up to proper test pressure...

I took these a fast as my iphone would let me... Start, Spray, and then Full of Mist....

See the spray hitting the Glass on the left side????

Last edited:

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

Good examples and explanations on how to set ring gaps were posted. I believe Cummins specs the top ring @ .038-.042 and the bottom @ .028-.032. This is off the top of my head so don't take this for granted...I don't have my manuals in front of me. Also...for the monotherms it will vary because of expansion due to heat. It should be pretty close to stock...I could also be talking CHIT since I have never installed a set.

Ring gaps also vary due to power being made, charger pressures, and even nitrous applications all have there ring gap requirements.

I feel your pain on things not working. It has happened to me many times in my own projects (just ask those people when a transmission could not hold more than 400 hp)! The people you meet in this community...at least the folks that have been in this game for 10 plus years are all top notch including some of the newer ones. The help you have received has been not only for you but for them. It is the experience in anything that we do that makes up better, and diagnosing the problem is were we all win. I have no doubt that your truck will be done properly by the people working on it. They have all been stand up and NO amount of money can speak up for that.

Thank you for the specs, post, and the support!!

:Cheer:

No, thank you!!! Im glad we got a chance to talk because now Im sold on Garmon. Maybe one day I will have Jeff build me a motor. Im really tossing the idea of it around. I guess the only thing I will need from him is a price. Im stoked to get this trans, I feel like a little kid waiting for Christmas. This sucks, I hate anticipation and waiting.

Im really hoping this is going to be an easy fix for you.

Your going to love it!!

I'm getting upgraded to his new latest Fat shaft stuff..Phil T. is changing my converter.... He told me to TRY and go break it!!!

I can wait either..

Thank you for the specs, post, and the support!!

:Cheer:

Your going to love it!!

I'm getting upgraded to his new latest Fat shaft stuff..Phil T. is changing my converter.... He told me to TRY and go break it!!!

I can wait either..

Well thats the wrong thing to say. To you anyways LOLLOLLOL

Joesixpack

Pull'n it.

- Joined

- Apr 4, 2008

- Messages

- 4,118

Those specs are wrong BTW....LOL I mean if your going to post specs might as well get them right,

Factory specs,

Top ring, min .011 max .023

second ring min .035 max .054

Oil min .011 max .030

Now thats factory, on a HOT build you'd likely open it up a bit.....YET I've pulled one apart that was a bottle baby at .014 and it was living just fine, don't recommend it but it did.

On the nozzle DAMN....

Factory specs,

Top ring, min .011 max .023

second ring min .035 max .054

Oil min .011 max .030

Now thats factory, on a HOT build you'd likely open it up a bit.....YET I've pulled one apart that was a bottle baby at .014 and it was living just fine, don't recommend it but it did.

On the nozzle DAMN....

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

Well thats the wrong thing to say. To you anyways LOLLOLLOL

HA!! That's for dang sure!! I make a GREAT Test subject!!

But funny thing is, My Garmon (standard size Billet tranny) has lasted through 4 engine builds!!! :rockwoot:

I don't seem to ever have tranny problems.. a testament to Garmon for sure..as well as the Opie shafts...

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

Those specs are wrong BTW....LOL I mean if your going to post specs might as well get them right,

Factory specs,

Top ring, min .011 max .023

second ring min .035 max .054

Oil min .011 max .030

Now thats factory, on a HOT build you'd likely open it up a bit.....YET I've pulled one apart that was a bottle baby at .014 and it was living just fine, don't recommend it but it did.

On the nozzle DAMN....

So, with my monotherms... in YOUR opinion...What should I set my gaps at??

Stay as close to stock as possible for my 800-850 range??

Or simply just go with what Eric suggest?

BTW.... I wish you were closer so you could do my Mono's like you did with the oil squirters!! :bow:

Should I consider trying to find someone to do that to mine?

Last edited:

Joesixpack

Pull'n it.

- Joined

- Apr 4, 2008

- Messages

- 4,118

So, with my monotherms... in YOUR opinion...What should I set my gaps at??

Stay as close to stock as possible for my 800-850 range??

Or simply just go with what Eric suggest?

BTW.... I wish you were closer so you could do my Mono's like you did with the oil squirters!! :bow:

Should I consider trying to find someone to do that to mine?

Not if the interval between builds is 4000 miles! It will be fine without, a tow monster that had to live at 600hp all day is were you would do it.

The specs Eric gave are safe, do doubt, but I know you can get away with the top end of the factory specs, ~.020 (double on the second) or so......at least on my pistons because the top ring is down further than stock.

Your newer pistons, they might have raised the top ring land.....I'd have to hold one....BUT I doubt it, this would take more consideration, as you bring the ring closer to the fire the more it expands.