Well Lets look at some

Mods while were in here.[guitar]

Note I am in no way responsible if you do this and burn things up or get a ticket for excessive acceleration [coffee]

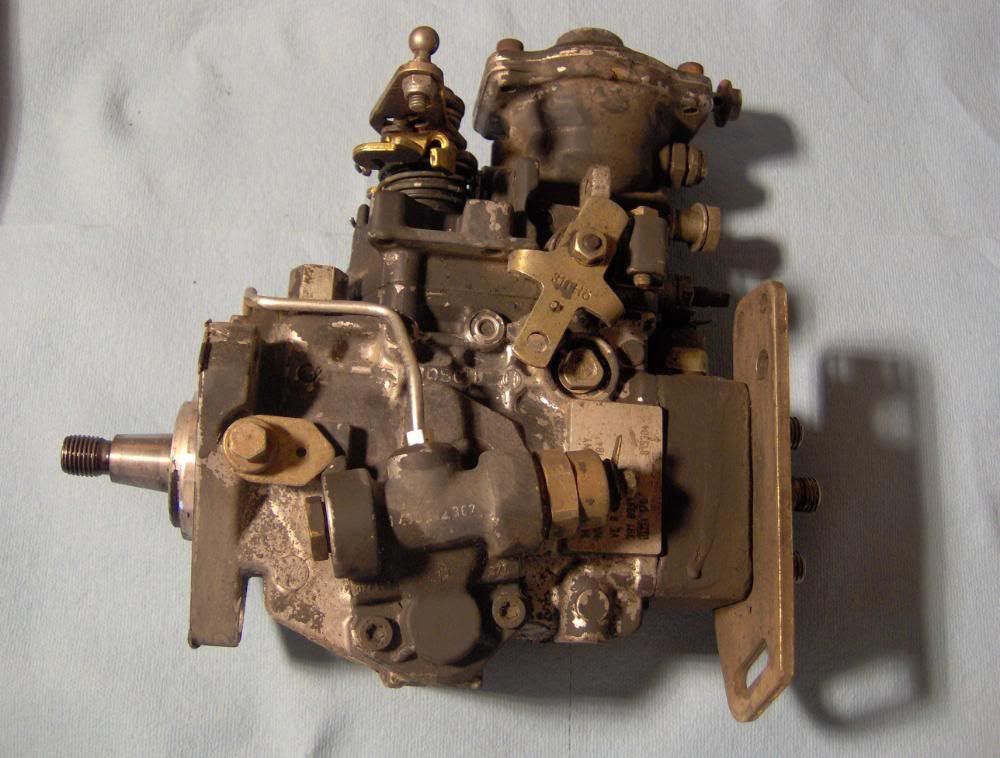

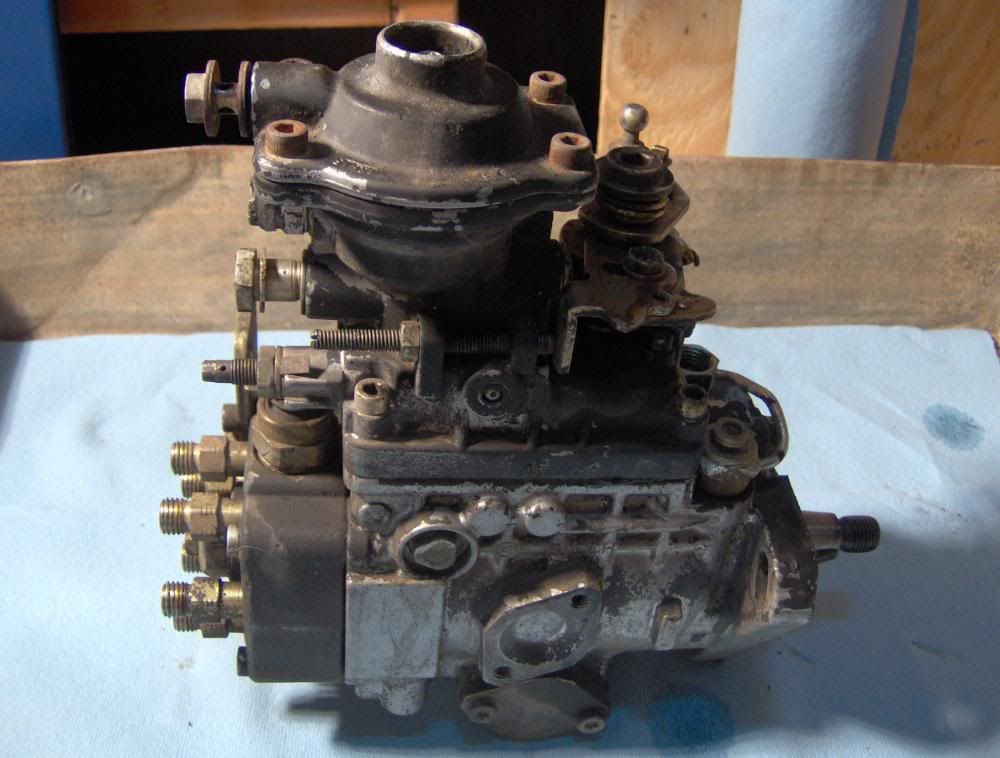

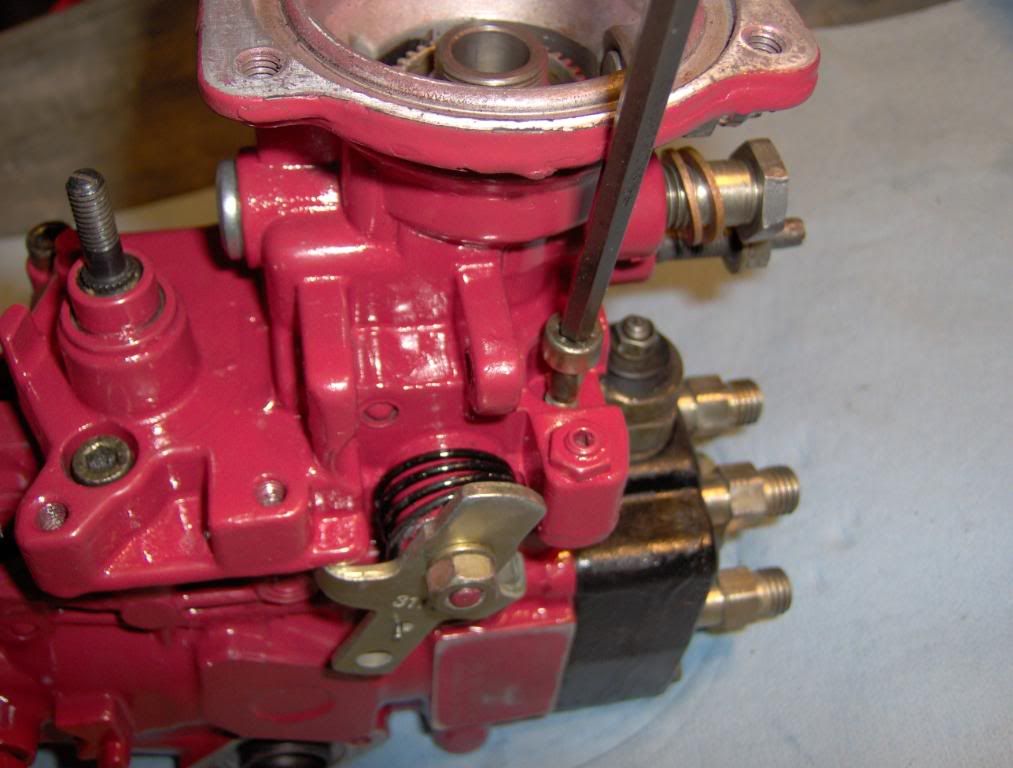

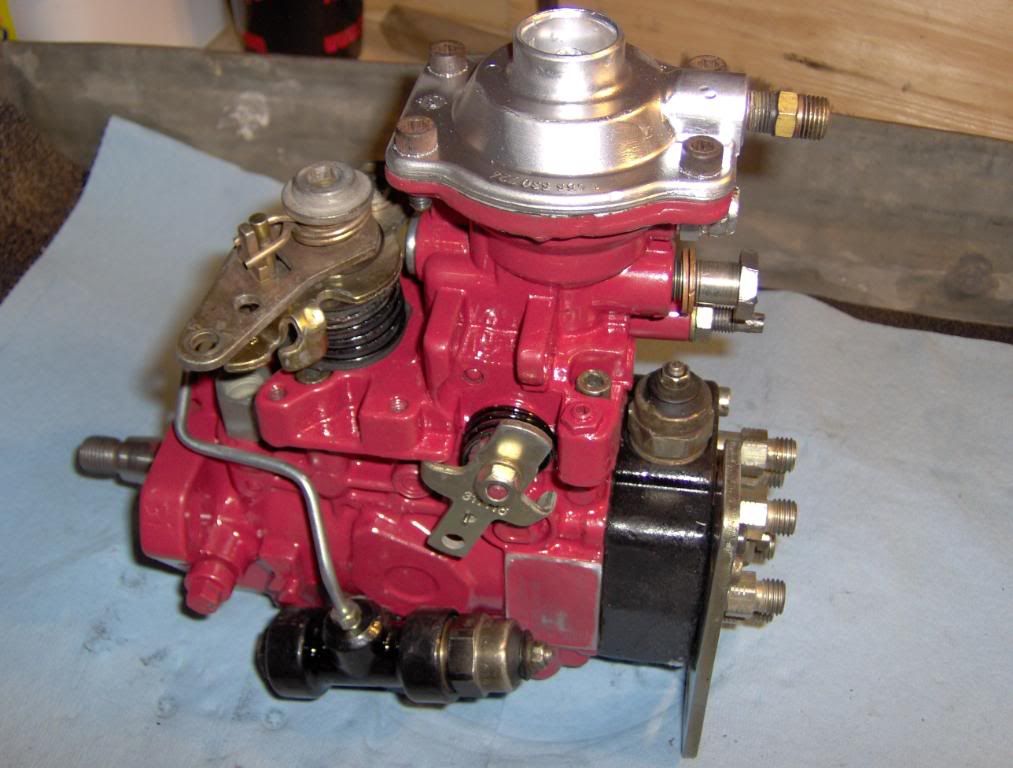

Lets start with fuel pins

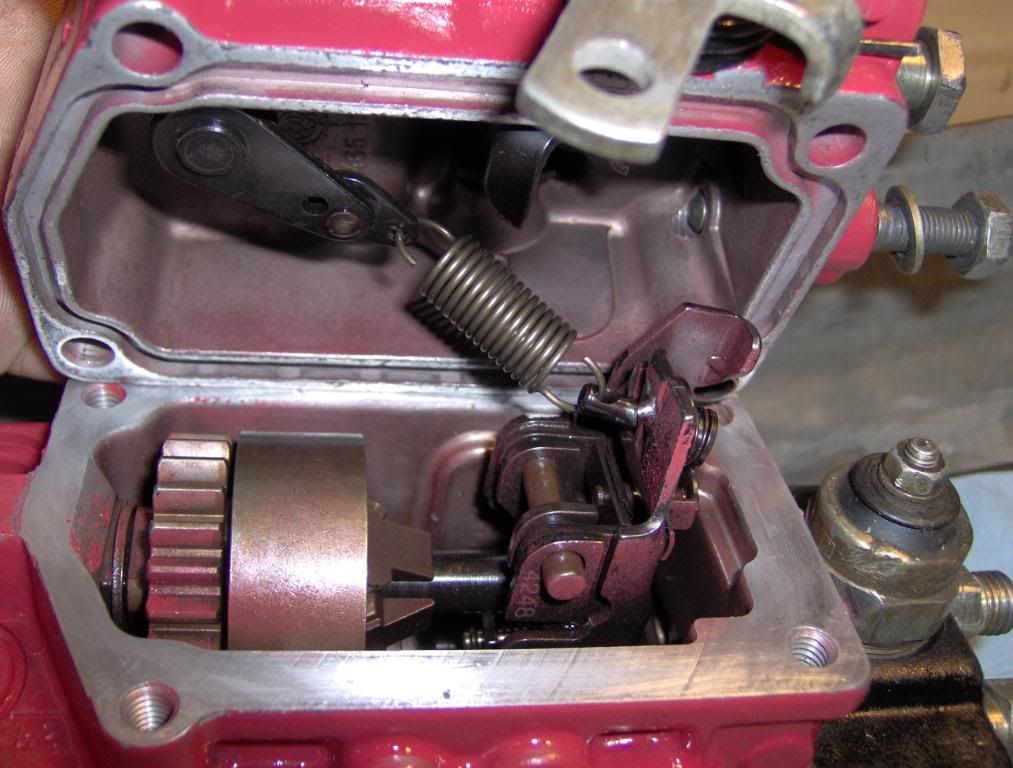

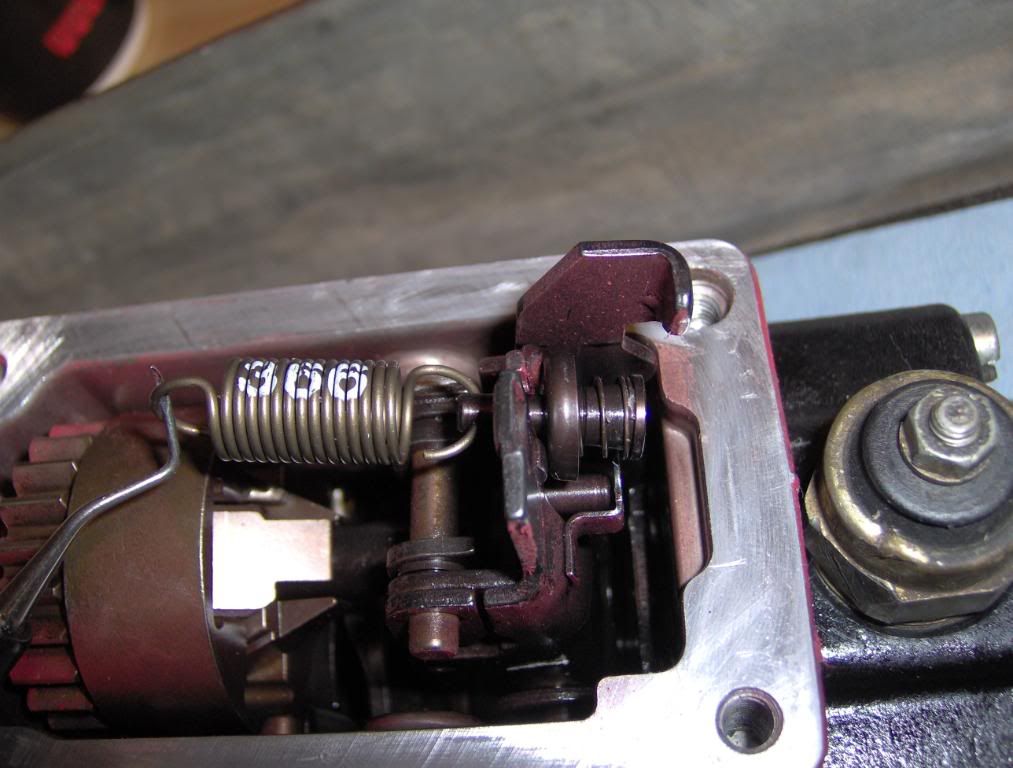

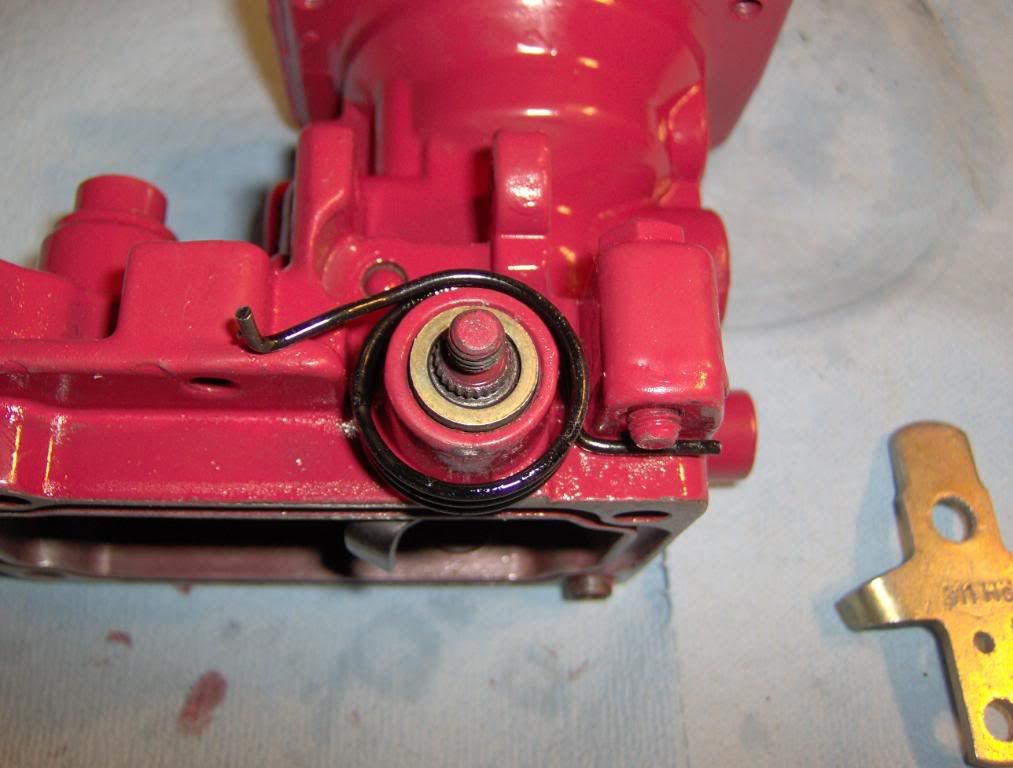

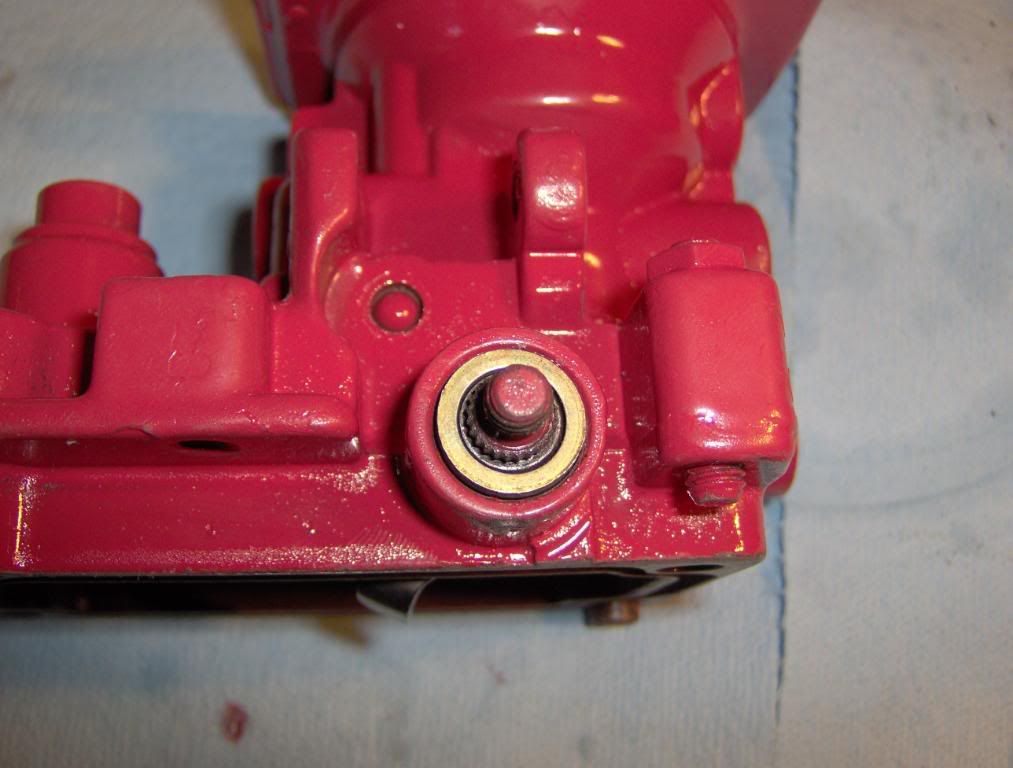

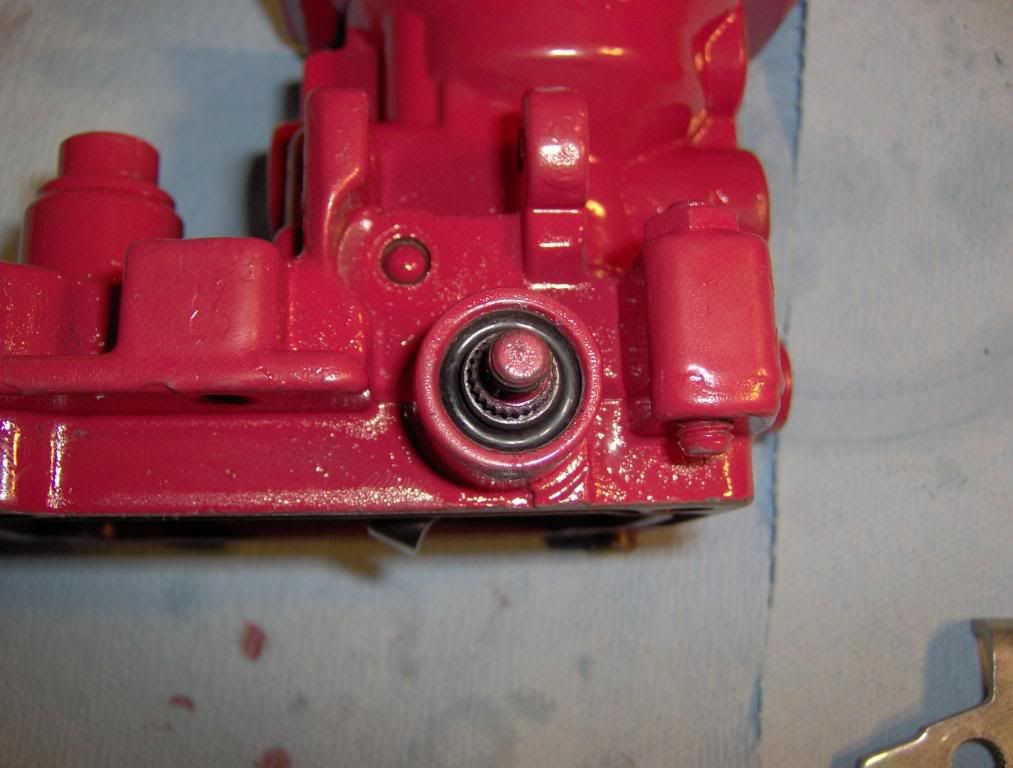

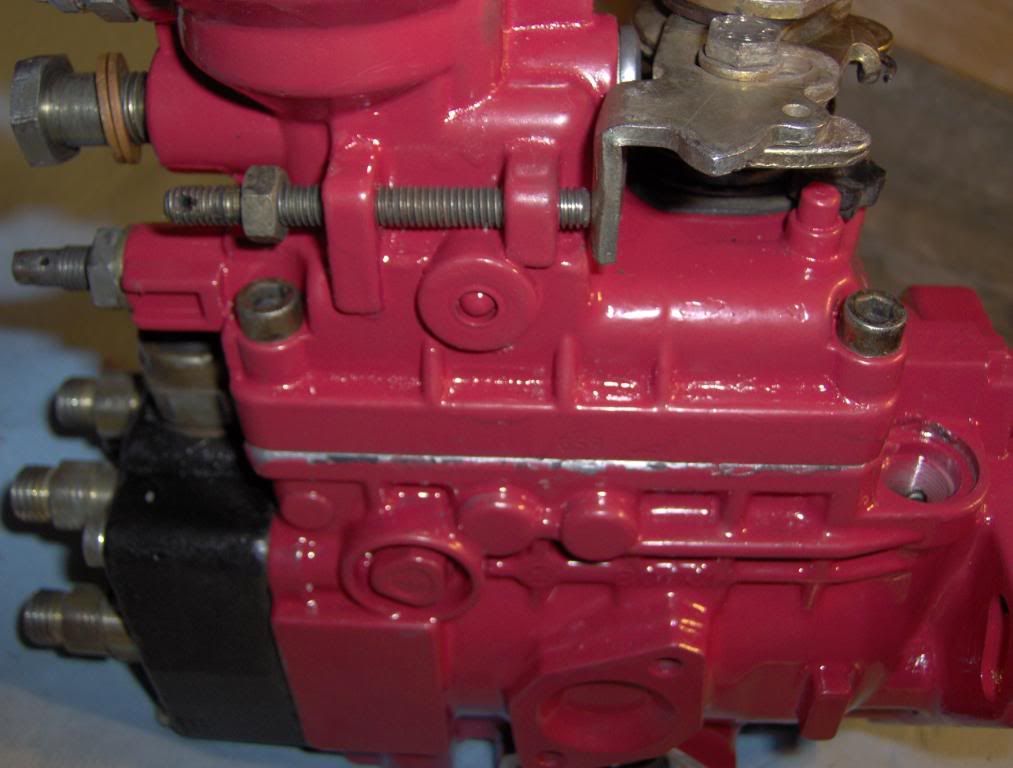

Fuel pins do the same job as a cam plate on a P-7100 pump. They change how much fuel is delivered in relation ship with boost. As boost builds it pushes down on the diaphragm and pushes the pin down allowing more fuel. There is a spring under it that holds it up and is adjustable and can be set to speed up or slow down the fuel rate in relation to boost. turning the star wheel at the base clock wise will put less pressure on the spring allowing the fuel rate to increase at lower boost = more smoke at lower boost, Counter-clockwise will put more pressure on the spring and slowes the fuel rate at lower boost levels = less smoke at lower boost.

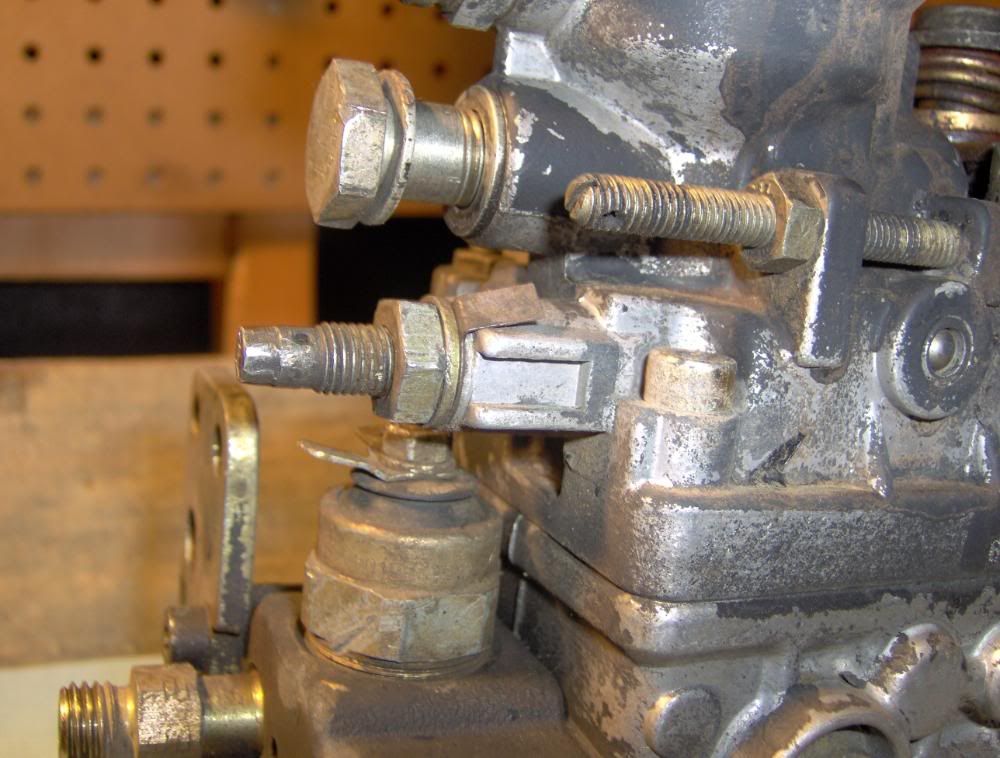

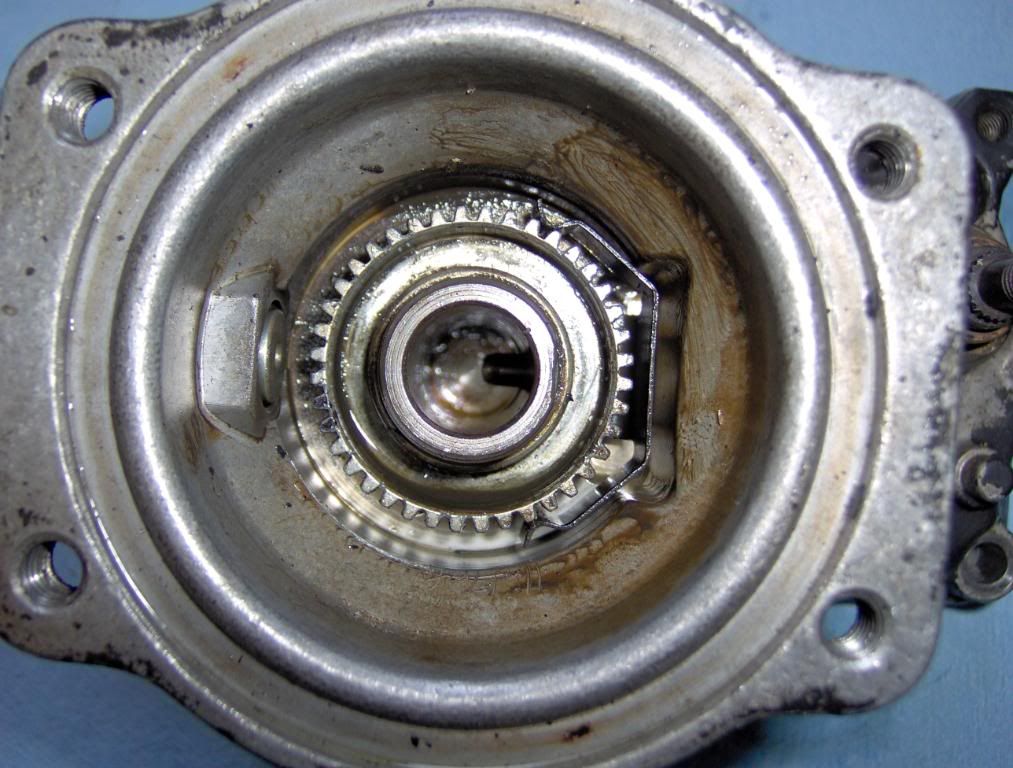

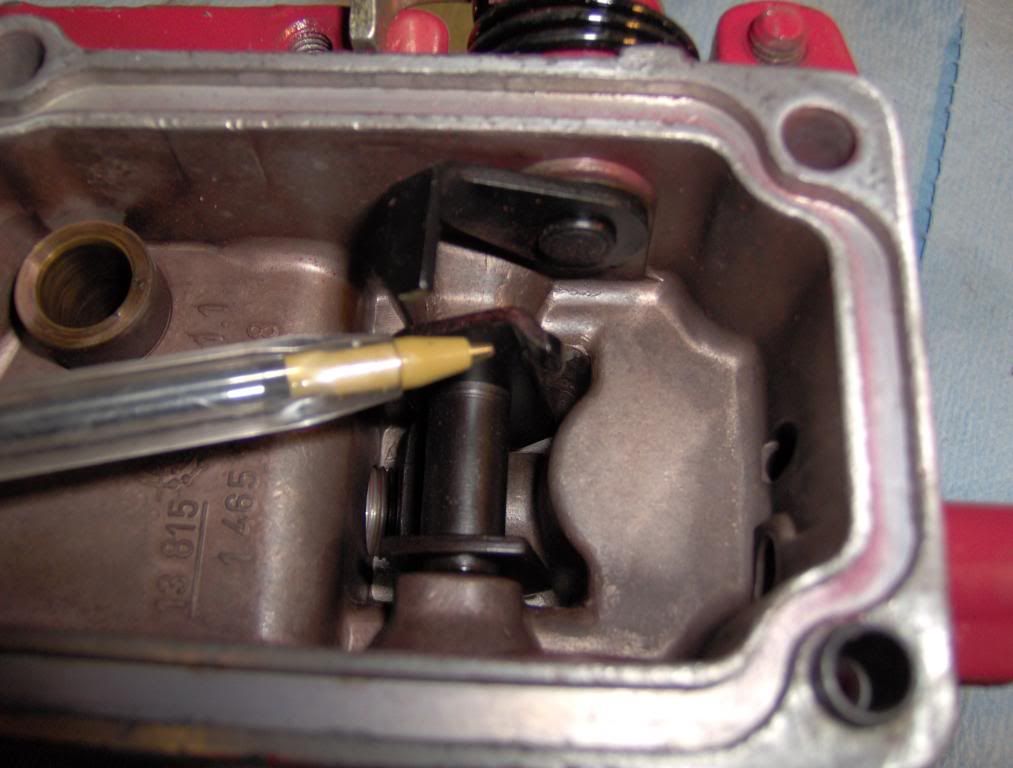

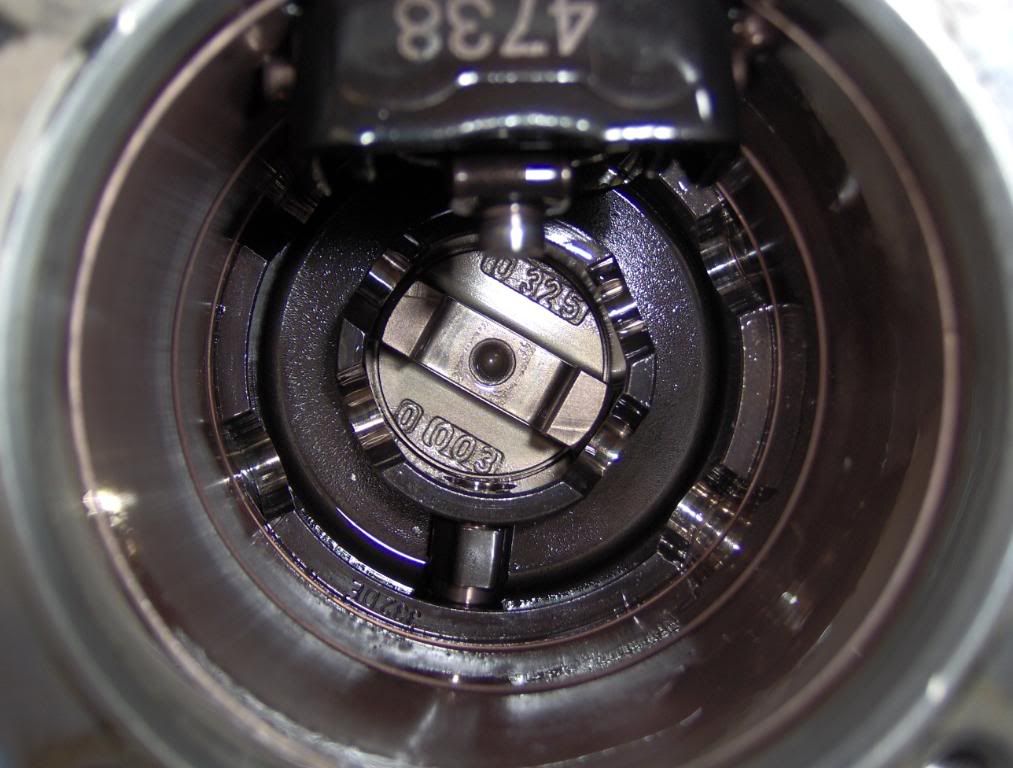

this is the small pin that rides on the fuel pin. It comes out from the front of the pump

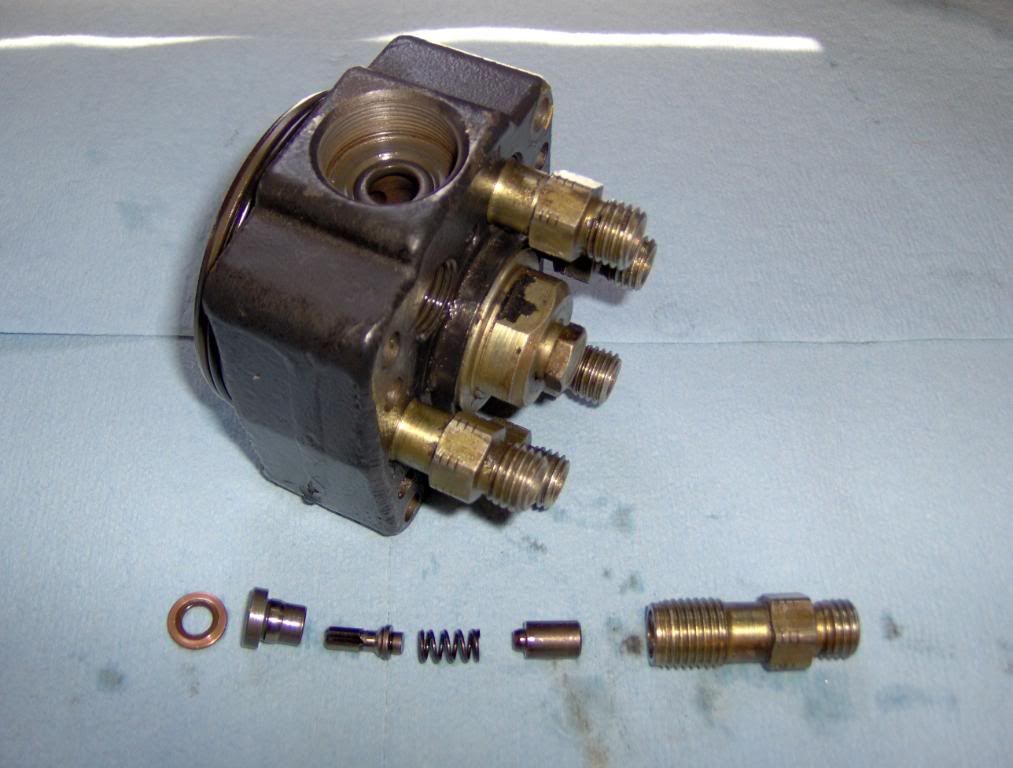

the one on the left is a Bully Dog, center is stock, right is Denny T.

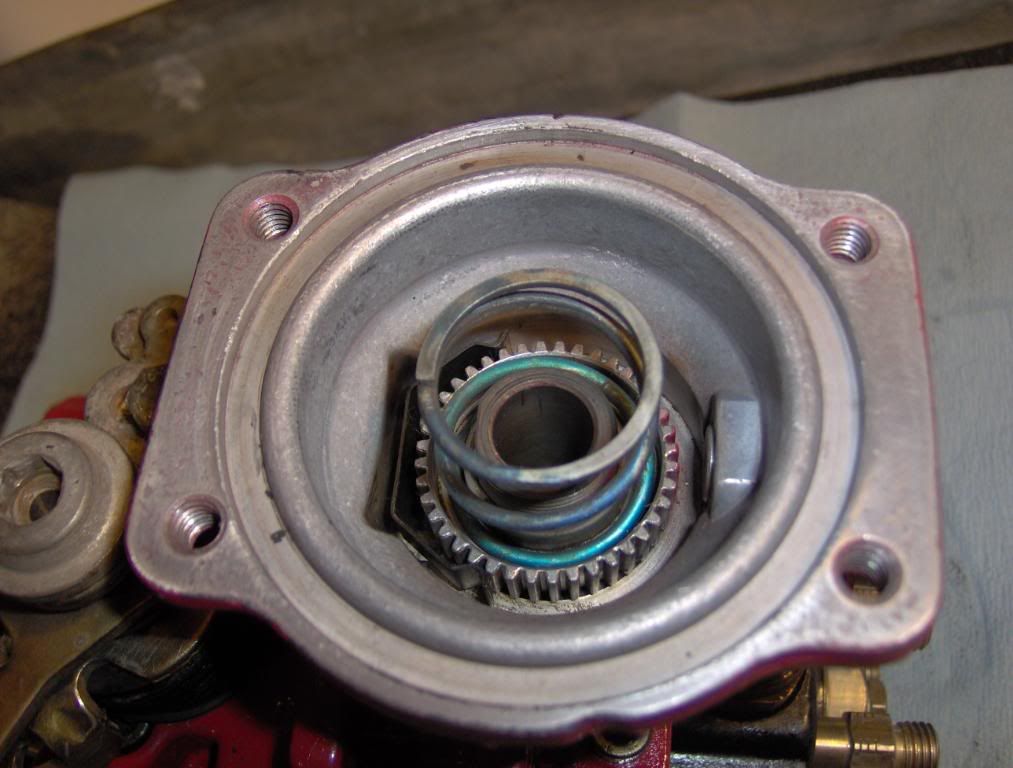

The stock one can bee turned were the eccentric cone is to the rear of the motor thus allowing the pin that rides on it to extend farther out and give more fuel. This is free and will give a noticeable bump in power.

The one on top is a Bully Dog the other is a Denny T. I ran both in my truck and found (like many others) that the Bully Dog made good power but was way to soft and gouged and would stick. The Denny T is maid from very hard SS and will just polish the area and is a lot cheaper. The Denny T pin gives a real boost in power over the Bully Dog and has held up great. DO NOT try to go cheep and make one from mild steel it wont last 100 miles if that[nonono]. There are others out there but I have not tryed them my self.

On the top cover (silver price on top of this pump) there is a Torx head screw that sets the starting depth of the fuel pin at 0psi boost. Ofter called the "Smoke Screw". It can be set deeper CW to give better take off power be for boost comes up but also creates more smoke. It can also be set for less low-no boost fuel and less smoke for pulling and or to compensate for large injectors to keep smoke under control.

op:

op: