Redrider2911

New member

- Joined

- Nov 19, 2015

- Messages

- 780

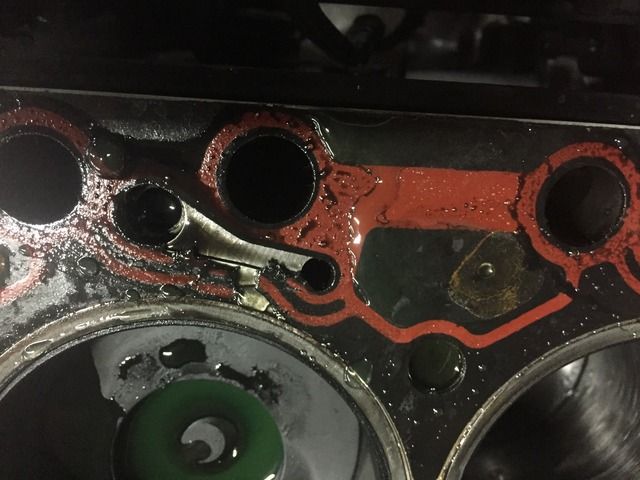

After seeing this I am definitely 99% sure that this head indeed isn't flat at all. So it's off to the machine shop tomorrow, curious to hear how far out it was.

What I am still confused about is how does a blown gasket on the drivers side lead to pushing oil out the passenger side? Anyone have any insight to this? Also confused on why the gasket is separating and bubbling up in areas that aren't clamped between the block and head. Was this just a bad gasket? I'm pretty confident that it was a genuine cummins gasket after watching a few comparison videos.

I'm pretty sure that at least one of these ports had to of been blown since the first drive. It was burning blue smoke quite a bit and I had ridiculous blow by. I was just telling myself that it was only because this engine didn't even have 100 miles on it and the rings needed time to seat, plus I have read that some blue smoke can be attributed to cold diesel and it has been in the high 20s, low 30s. Apparently I was wrong...

What I am still confused about is how does a blown gasket on the drivers side lead to pushing oil out the passenger side? Anyone have any insight to this? Also confused on why the gasket is separating and bubbling up in areas that aren't clamped between the block and head. Was this just a bad gasket? I'm pretty confident that it was a genuine cummins gasket after watching a few comparison videos.

I'm pretty sure that at least one of these ports had to of been blown since the first drive. It was burning blue smoke quite a bit and I had ridiculous blow by. I was just telling myself that it was only because this engine didn't even have 100 miles on it and the rings needed time to seat, plus I have read that some blue smoke can be attributed to cold diesel and it has been in the high 20s, low 30s. Apparently I was wrong...