HRDROKN

Prestige Worldwide

- Joined

- Apr 16, 2008

- Messages

- 621

Hey Guys,

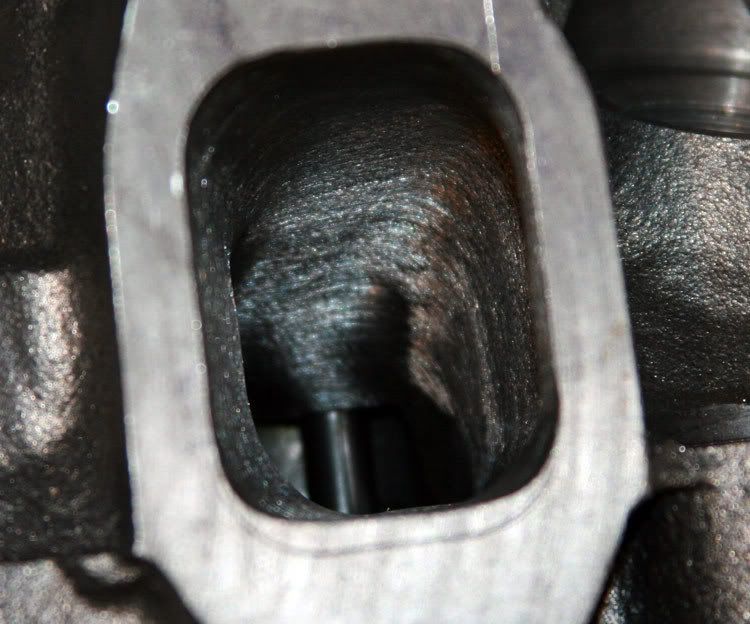

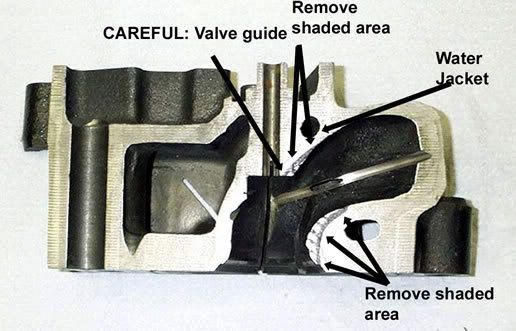

I'm knee deep so to speak.... this will be my first multi-cylinder port job and as such I'm keeping it pretty basic! I'm thinking that I might not take the gasket match all the way to the line.... maybe a 32nd short? Just to compensate for any error on my alignment and/or any gasket expansion?

What do you all experts think?

:Cheer:

I'm knee deep so to speak.... this will be my first multi-cylinder port job and as such I'm keeping it pretty basic! I'm thinking that I might not take the gasket match all the way to the line.... maybe a 32nd short? Just to compensate for any error on my alignment and/or any gasket expansion?

What do you all experts think?

:Cheer: