Chris Tobin

New member

- Joined

- Jun 20, 2008

- Messages

- 2,662

You should sand and polish the flycut portion of the valve covers... It would look gooood!!!

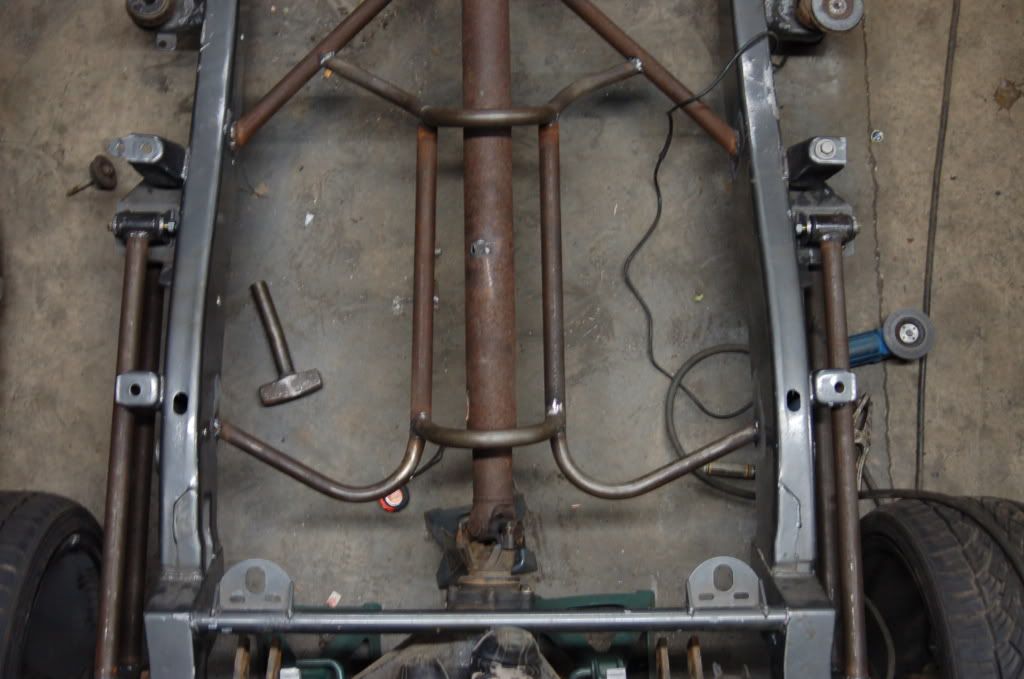

no chris i'm gonna run the oval tubing, that was just my redneck attempt at doing it myself. i should have the piping later this week. i'm also going to run an exhaust brake which should be fun to try and fit in there.

once i'm done mocking up all the pipe. i'm going to send it off to MBRP and have them coat it with that black powercoating they use.

thanks. well the tip is just in there as a reference right now, it will be pointed the other way and be color matched to the truck.

what do you mean the turbo needs to be clocked? the 06 turbo?