I am still interested. Done anything?

Why, yes....yes I have. It's a fiasco but it finally ended last night. :snoop:

So...….it started when I went to move the Chelsea PTO housing and the Vickers Vane pump from the FS-5005 onto the FS-5106 that I got from Signature600. The gear on the PTO housing wouldn't match the 5106 PTO gear. I took them both as separate units to Blumenthal Heavy Duty in OKC Dec 2015. I told them "I need this to go on there and new seals put in everything. I don't want to build a new truck and have it leak."

From the day I got it back, installed it into the truck, and filled it with synchromesh fluid...the mofo has leaked out on the PTO housing. Fast forward to a few months ago when I got it running. I called Blumenthals and they said sure, bring it back, we will fix the leaks. I also explained that it doesn't pump now and I have no fluid pressure. They said they'd take a look at everything.

A week ago last Friday, I go to pick it up and they have fixed all the leaks, put new seals in everything, replaced the PTO shaft and a filler plate yada yada yada. I paid for all the parts and they covered all the labor since they didn't seal it up the first time like the work order showed. Great folks, no issues with them, everything was dandy and fine. We discussed the fact that it still didn't pump and I said I'd dig into it since I didn't want to pay the for labor to chase it down.

Fast forward to night before last. The wife and I spend a few hours trying to figure out why there wasn't any pressure. Then yesterday after work, I had her look under the truck while I bumped the PTO after taking the pump back off again. She told me the gear was rotating CW. Now, this is the first time I had checked rotation because I was told "the two transmissions both have the same PTO rotation." If the pump worked on the old one...why the hell wouldn't it work on the newer one, right? Wrong. The pump was set up for CCW rotation. So after I took the input housing off, reversed the plates and rotor in the cartridge assy, and put it all back together.....we have hydraulic power!!!! It was a long, drawn-out, stupid deal....but I did learn how to reverse a vane pump and lots of other junk so it wasn't a total waste of time....even though it should have been set correctly the first time it was assembled.

I am having a few air brake issues, though. I've been in touch with Haldex trying to figure it all out. Sometimes the dryer purge valve will mysteriously open and start bleeding the wet tank. I'm still trying to figure out this saga.

I really need to do exhaust now that I can put the dump bed back on. I needed hydraulics to raise and lower the bed. The stack needs to be set so it doesn't interfere with the bed so it needs to be on the truck....but I need to raise it up and down to run the pipe and make brackets. I need an HX-40 housing clamp and fitting and some pipe and elbows.

So....it needs to be air brakes then exhaust. After that I should be able to move on to the hood stretch.

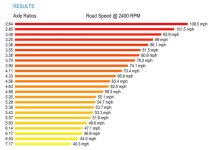

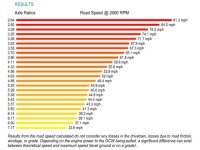

And I found out the gears in the rear end are 4.88 on the high side. Looks like 60 mph is going to be my max according to the road ranger calculator. Might need to lower the ratio in the next year or two. That's gonna suck on the highway.

O, and I still need to order a tachometer sensor. I need to get the tach on the dash working also.