Hamilton Cams

ignorant

- Joined

- Jun 28, 2007

- Messages

- 2,639

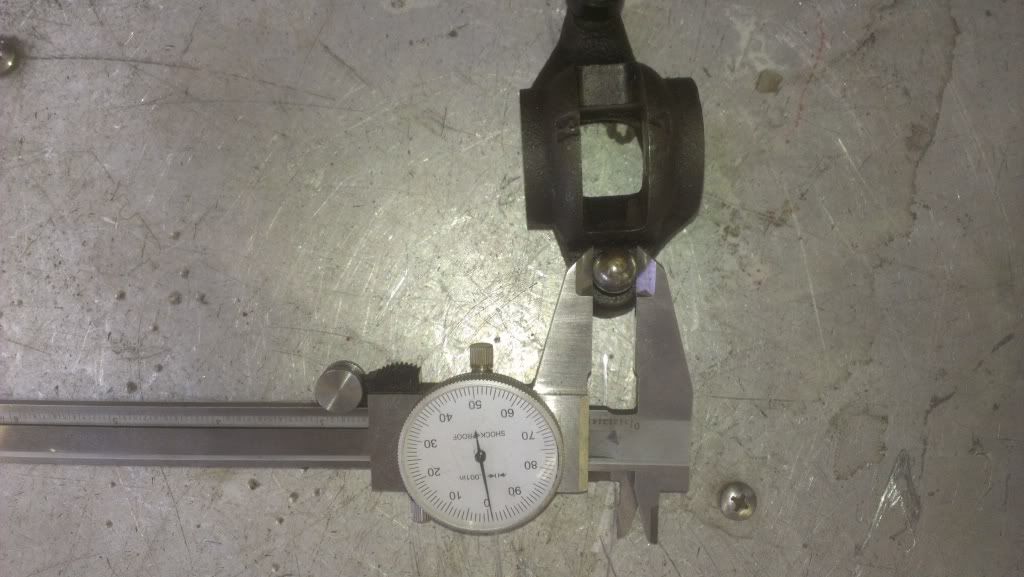

Taper, in every instance makes the pushrod weaker when compared to a straight wall equal to the largest O.D. of the tapered pushrod. Adding material to the center of the 3/8" pushrod is adding considerable weight, without adding as much to the pushrod's ability to resist buckling. It is not a matter of opinion but a calculation based on Euler's equation for column buckling strength. When calculating the buckling strength of a steel column(pushrod), the outside diameter is more important in most cases than how thick the wall is. If there is a taper, then you are reducing how rigid the pushrods is and making it weaker. The three determining factors are length, Outside diameter, and wall thickness. The alloy of steel used is not a major factor.

7/16" pushrods are heavier, they also transmit more of the cam lift to the valve than the tapered or the 3/8". Nascar and other motorsports that spin over 9,000 rpm for extended periods don't use the lighter 3/8"(.375") or the heavier7/16" (.4375") but 1/2"(.500") and 9/16" (.5625"). By your argument they should be going for the light weight thinner pushrods. Greg, as a "Cam Manufacturer", I would expect you to know that there is more to be gained from more lift, created by a more rigid valvetrain, than a few grams savings with reduced lift. I would also expect you to know that a 12 valve pushrod has a; 3/8"(.375") cup , a 5/16"(.3125")ball, and that 3/8"(.375") is different than 10mm (.3937"). After visiting Bullet 3 weeks ago, I would also expect you to know that the Chinese cams with narrow lobes you use for your reground Cummins cams will not last as long as wider lobed cams with superior alloy. Is your bore spacing on your new block allowed the same variance that your pushrods are? May I ask how much you are getting for the Chinese cores?

I can see that you didn't take my advice. Good luck on the forums.

7/16" pushrods are heavier, they also transmit more of the cam lift to the valve than the tapered or the 3/8". Nascar and other motorsports that spin over 9,000 rpm for extended periods don't use the lighter 3/8"(.375") or the heavier7/16" (.4375") but 1/2"(.500") and 9/16" (.5625"). By your argument they should be going for the light weight thinner pushrods. Greg, as a "Cam Manufacturer", I would expect you to know that there is more to be gained from more lift, created by a more rigid valvetrain, than a few grams savings with reduced lift. I would also expect you to know that a 12 valve pushrod has a; 3/8"(.375") cup , a 5/16"(.3125")ball, and that 3/8"(.375") is different than 10mm (.3937"). After visiting Bullet 3 weeks ago, I would also expect you to know that the Chinese cams with narrow lobes you use for your reground Cummins cams will not last as long as wider lobed cams with superior alloy. Is your bore spacing on your new block allowed the same variance that your pushrods are? May I ask how much you are getting for the Chinese cores?

I can see that you didn't take my advice. Good luck on the forums.

Last edited: