TheBigNasty

Project bish

- Joined

- May 9, 2007

- Messages

- 5,385

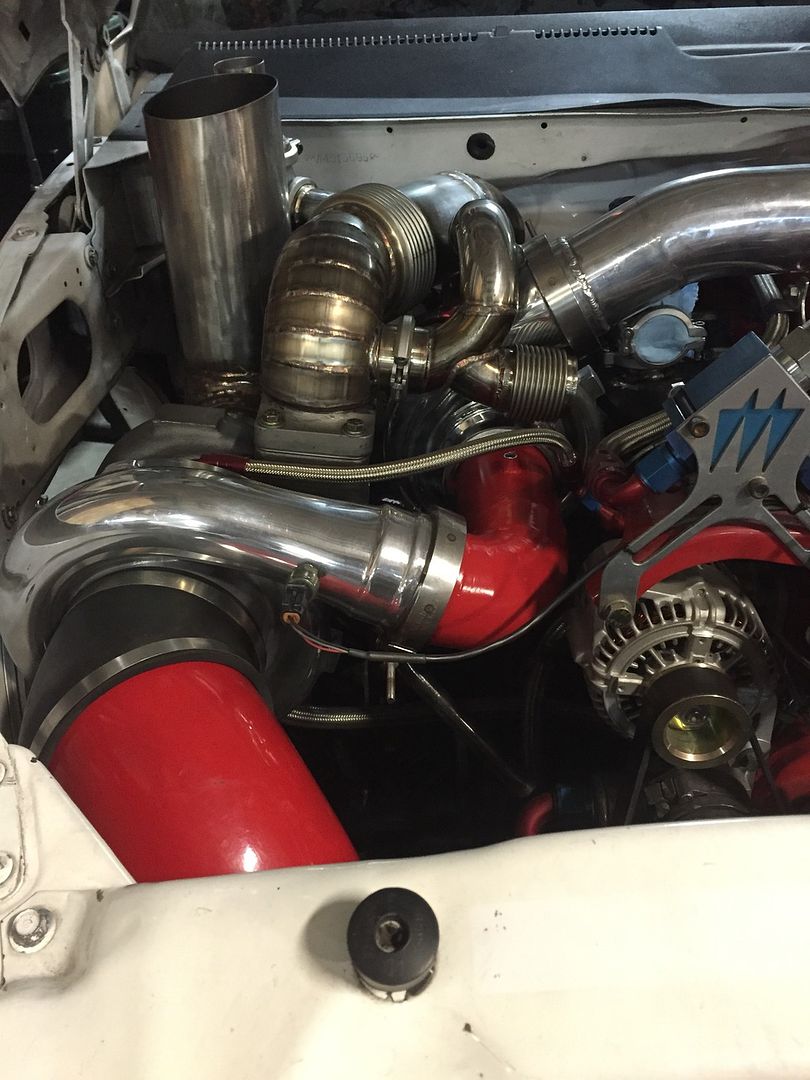

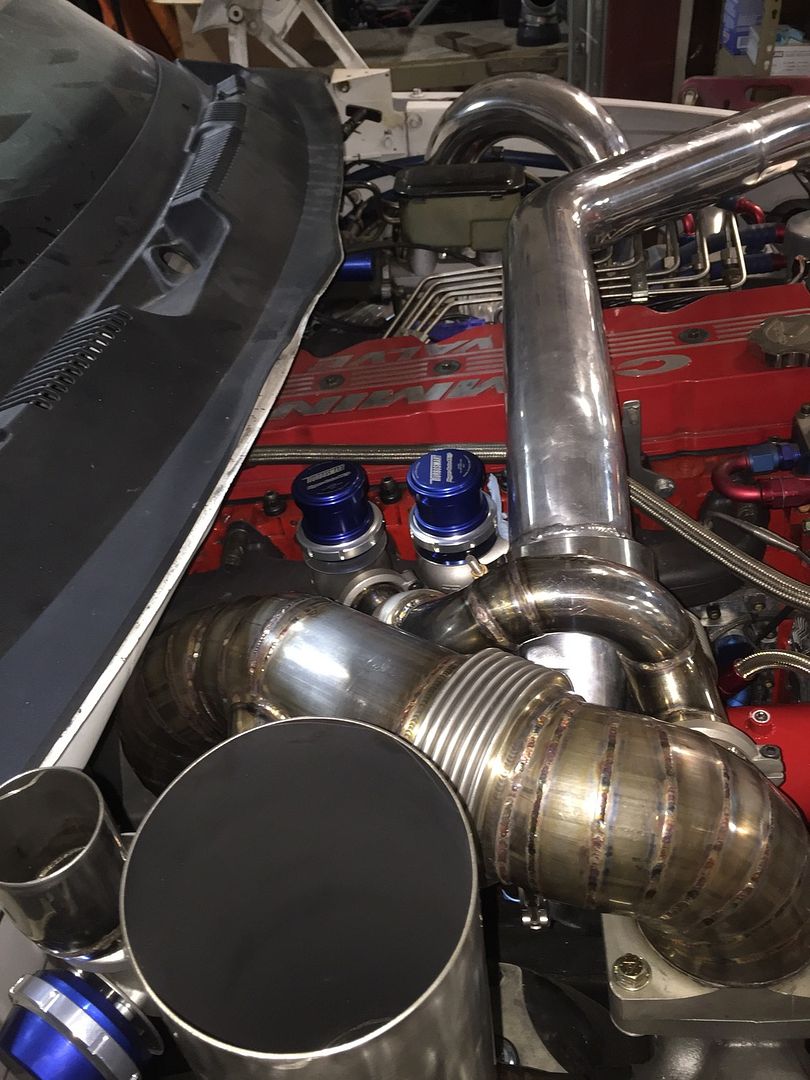

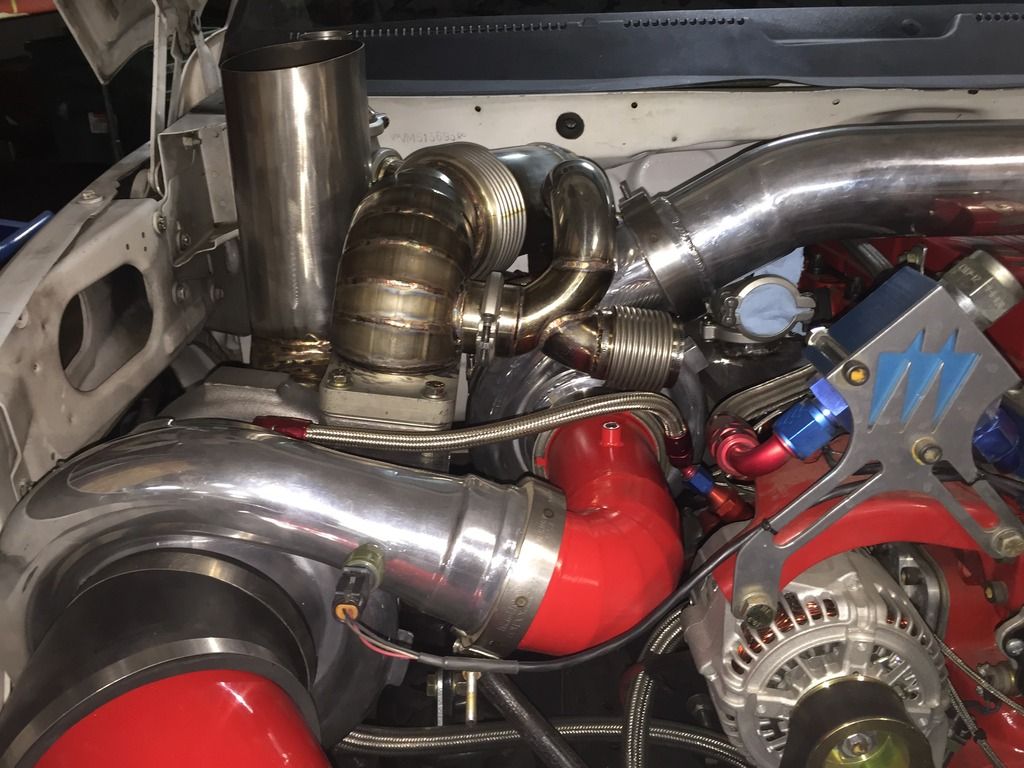

I am going to try a soup strainer screen on the dyno and see what the power difference is vs my current AFE filter. I don't think I can justify running a screen on the track though, especially if it's only worth 10-20 hp.

I jumped 100hp removing the filter. It was a terribly undersized unit though.