A singles is so much less problem, and will make 900 on fuel, and 1100 on nitrous , what would you not keep it simple , with a mild tune , 900 + hp with 27,000 of rail pressure .

Prove it!! Post the graph!!:doh:

And by the way, you don't need 27K psi rail pressure to make 900:doh:

I have spun it over a 1000 and never seen the fuel drop below 26000 .

All this on a very conservative dyno

Again the problem is not in the pumps, but in the fact that a programmer has big limits, use an other methods to maximized rail pressure and not let the programmer pull back on rail pressure because of a quirk.

Enough with the "very conservative dyno" crap*bdh* If that was, in your words, "your first dyno event" and the "same dyno I always use", you have no reference:doh:

Programmer pull back on rail pressure??

Maybe if your $hit wasn't such a hacked together piece of crap you wouldn't have all these "quirks" :shrug: LOL

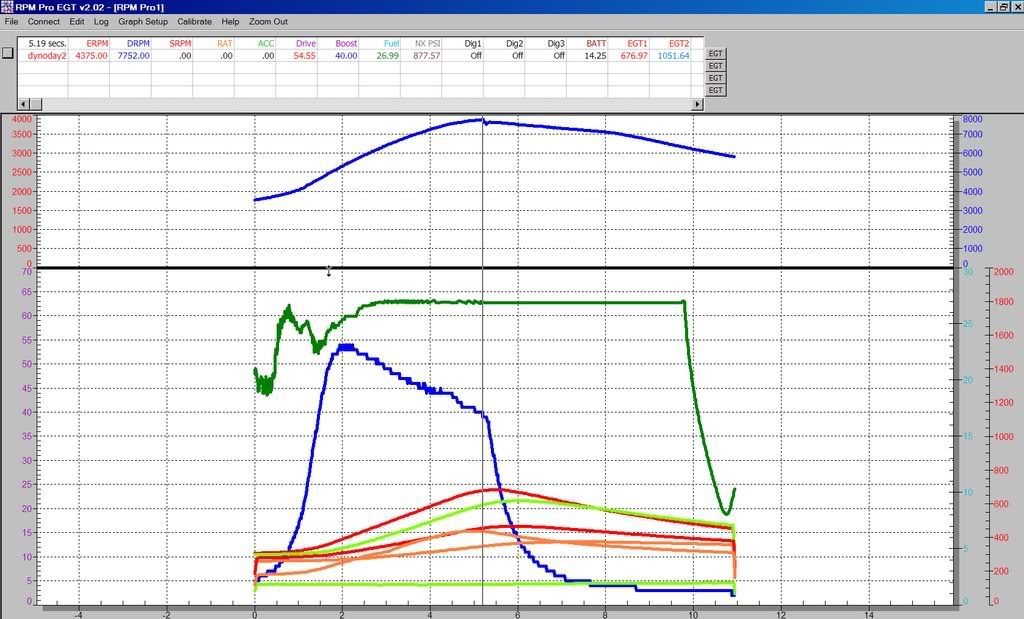

here is the run from sat.

the rail is 26.99 flat at 917 on a conserative dyno

Again, enough with the "conservative dyno" excuse everytime you post:bang

I know you think you are special and the ONLY one that datalogs runs, but you are not:what:

A datalog of mine below of a 878 hp FUEL ONLY dyno pull condradicts every single point you are trying so desperatly to make in this thread:doh:

I don’t believe the pump is over worked or maxed out, the pump is the same one , that’s been on the truck for quite a while with a lot of miles. The problem is with two pumps you have twice as much to go wrong, and the chance the electronics will let the pumps fight each other is very possible.

Please explain Ole' Wise One??..................This ought to be good:hehe:

This pump is nowhere close to the biggest that II dose, this is the 85% pump, Brady makes one much bigger , but I don’t need any more , if this had been on the any other dyno it would have been over 1050 hp.

Whats that........at least the 4th or 5th time in this thread alone you felt the need to mention how "conservative" it is?:hehe: If you can make 1050 hp......show the graph!!

There are a lot of reasons not to put twins on, this is just the route I wanted to go. It’s just so much easier to bolt a pump on , and be done with it , and how many are wanting more than 1000 hp. There are way too many 600 hp twin cp3 truck, I think a lot of people get mislead ,

You should know!!!! Because you are at the head of the "misleading" pack!!:kick:

oh the lack of RPM graph . I blanked out the RPM graph to keep some things to myself .

Only one of two reasons. Either it didn't run up that high which proves you don't have the programming you think you do, or it did which proves you STOLE the programming:doh:

Below is a datalog of a 878 hp fuel only pull on the dyno. This is with dual STOCK CP3's, Smarty TNT Race on 9 and NO pressure box. And since I don't need to hide my BS

, you can see that it was pulled to 4081 RPM.

You DON'T NEED 26K+ of rail pressure to make that kind of power!! You just need to keep it around 22K and have enough FLOW!! In fact, you can see that the only time the rail sensor was maxed was on the pressure spike when the throttle was let off.

White = RPM

Red = Rail Pressure (x 1K)

Green = MPH

Grey = Throttle Posistion

Personally, I would go with duals