You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Homemade Trac-bars

- Thread starter coon smile

- Start date

Tcolesanti

ALL NIGHTER

- Joined

- Apr 30, 2006

- Messages

- 2,753

I like a full saddle over anything else. I built mine out of 3/8" plate.

Yours has a good design but I like to overbuild everything.

-Tom

Yours has a good design but I like to overbuild everything.

-Tom

Sledpuller

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 8,160

stacerbob said:Yes I see that & if it was a sled puller only that I didn't want to travel it wouldn't be a big deal. But what about a racer or driver? What happens when the rear can't squat due to the bars keeping the springs from growing? !

The bars bend, and /or shove the frame up into the cab.

I prefer a 12"-16" saddle, with sides the whole way to the top of the frame, bolted on. Spread the pressure point out across a larger area of the frame.

I like the shackle idea for street use, but it needs some sort of locking device to pull with(along with suspension stops in a pulling application.)

Also, upgrade the diff u-bolts to 3/4".

AsTroSS

problems start @80 psi

- Joined

- May 10, 2006

- Messages

- 4,335

stovepipe

New member

- Joined

- Sep 21, 2007

- Messages

- 215

Howling said:What typ of mount did you use for the frame end?

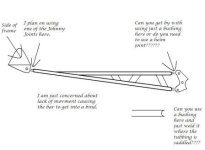

This is what I plan on using -

I made a two plate one on each side of each frame rail made out of 3/8 and put the heim on the bottom in the middle. the plates are 12" wide and the height of the frame. even made a place to put a safety strap just in case the heim or bolt snaps off.

Howling

Soot Sniffer

- Joined

- Apr 30, 2006

- Messages

- 4,304

Sledpuller said:The bars bend, and /or shove the frame up into the cab.

I prefer a 12"-16" saddle, with sides the whole way to the top of the frame, bolted on. Spread the pressure point out across a larger area of the frame.

I like the shackle idea for street use, but it needs some sort of locking device to pull with(along with suspension stops in a pulling application.)

Also, upgrade the diff u-bolts to 3/4".

I will build a bigger saddle to spread the load out then.I would love to bolt it on but with our hydroformed frames it makes it a little bit harder

coon smile

New member

- Joined

- Oct 25, 2007

- Messages

- 3,399

Howling said:Material as in everything for the bars and mounts or just the tubing for the bars?

bars and mounts.....

coon smile

New member

- Joined

- Oct 25, 2007

- Messages

- 3,399

from a structural standpoint...how critical is the number of bolts and bolt/hole spacing when connecting the saddle to the frame?

Tcolesanti

ALL NIGHTER

- Joined

- Apr 30, 2006

- Messages

- 2,753

Here is a pic of my frame saddle, full height of frame rail and built out of 3/8" plate.

http://www.competitiondiesel.com/forums/attachment.php?attachmentid=5616&d=1195320664

-Tom

http://www.competitiondiesel.com/forums/attachment.php?attachmentid=5616&d=1195320664

-Tom

Papuller86

pissing people off

- Joined

- Nov 21, 2007

- Messages

- 159

i will get pictures of the set up i made i use 3/8 flat stock for the brackets, 7/8 heim joints, heim joint inserts, 2x2" 3/8 wall square stock and and all grade 8 bolts the total cost for the materal came to about 300 (i get the best i could i hate doing things twice) it rides nicer on the highway, but is a little ruffer on the pot hole infested citys, but helps a ton when drag racing also

coon smile

New member

- Joined

- Oct 25, 2007

- Messages

- 3,399

thanks everyone for the posts and pics...this is really what i needed to get started!

coon smile

New member

- Joined

- Oct 25, 2007

- Messages

- 3,399

is there any advantage of using heims rather than top links?

Big A

Smokin Diesel Performance

- Joined

- May 6, 2007

- Messages

- 252

I used Pro Comp Traction bars. They work great. Just don't use the u-bolt style to clamp them to the axle tube. They can slip. Here is instructions and hardware specs on the Pro-Comp bars......Good Luck.......

http://www.explorerprocomp.com/PDFs/is/77082.pdf

http://www.explorerprocomp.com/PDFs/is/77082.pdf

jktcummins

24v GOD!!!! HAHAHA

- Joined

- Apr 1, 2007

- Messages

- 2,450

If you designed a triangulated set of bars could you get away from with using a pair of poly bushings at the axles and then a heim joint on the frame?????

jktcummins

24v GOD!!!! HAHAHA

- Joined

- Apr 1, 2007

- Messages

- 2,450