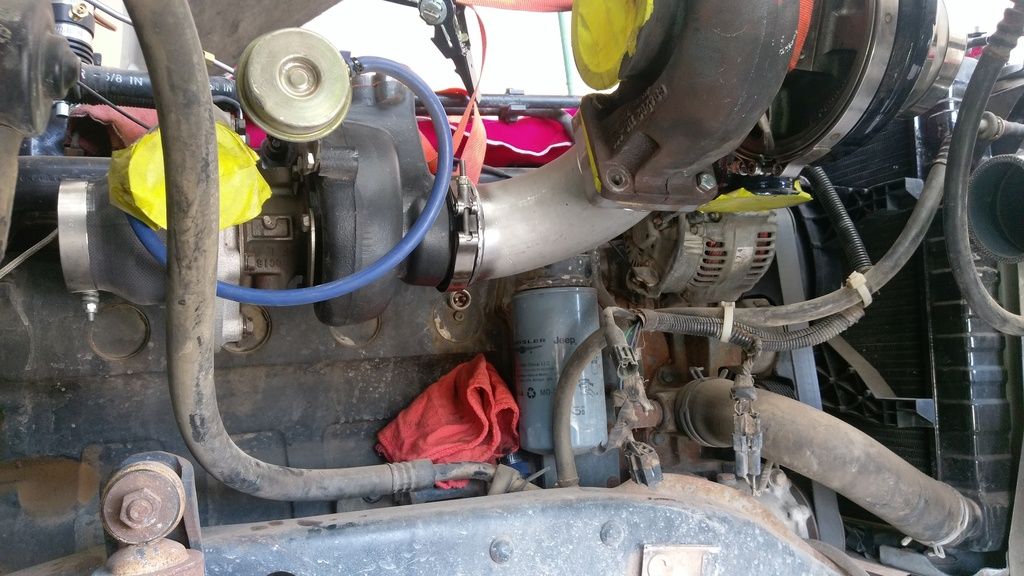

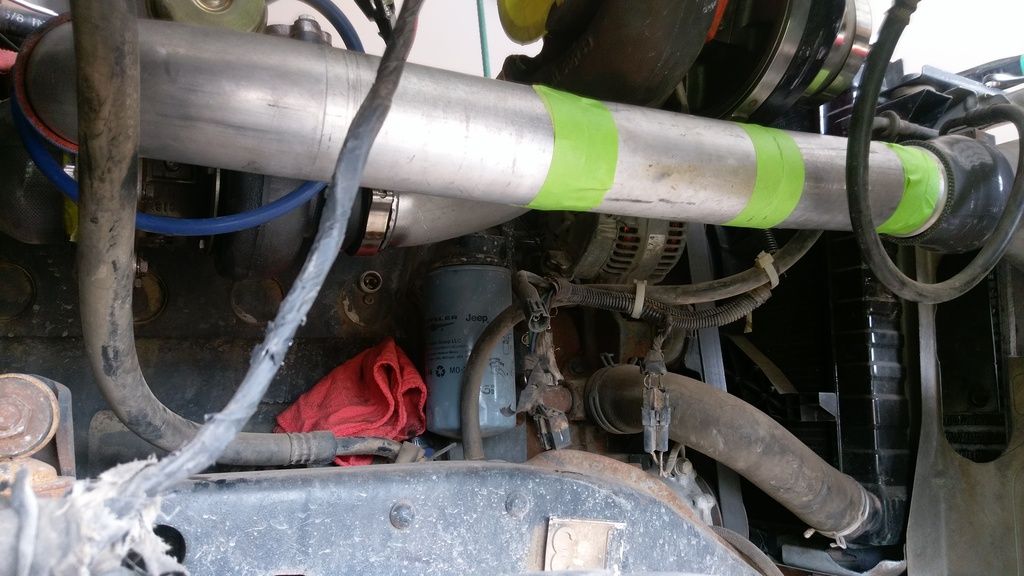

How much of an angle can a turbo survive? I set the inner fender in, did a couple pie cuts and tacked some inner stage pipe so I can get an idea. I think I can get the exhaust back and out, may have to do 3" for a short section.

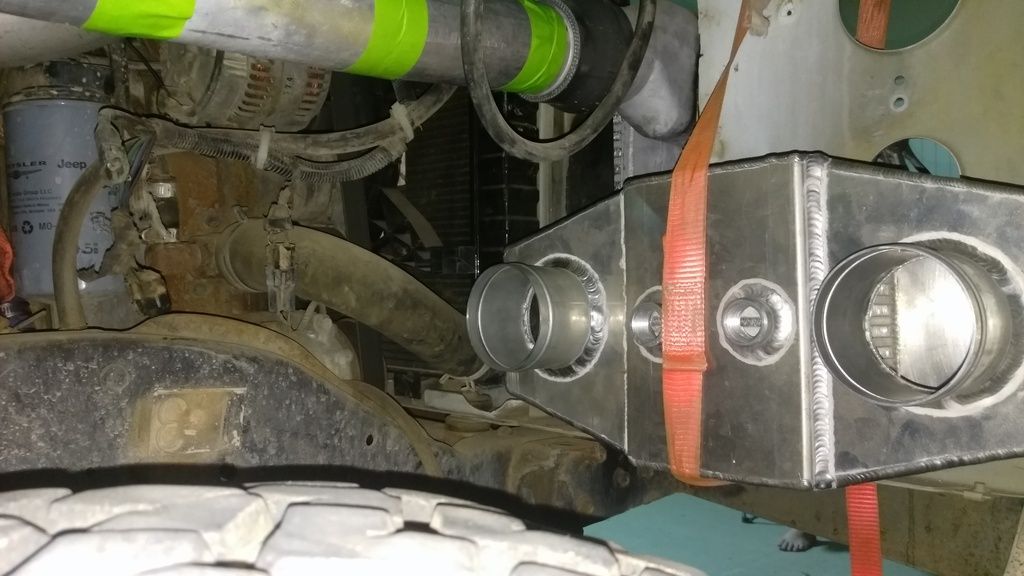

I brought the water to air up some and tilted it a bit. Helped a bunch for my pipe angles and keeping most of my inner fender. Air filter area is not much. I could do a 180 and have a good size filter but it would be sucking under hood temps in. I'd really like to build some thing that would get air that isn't under the hood feed to it. I'll have to build the pipes and mount it all, then decide on a filter. I see lots of guys just having a filter clamped to the primary, but I'm already at a disadvantage with the VE. I want to help it best I can.

I have no pictures right now. I forgot my phone at work and I'm on my wife's, I forgot my photo bucket password.....