takedown95

New member

- Joined

- Aug 18, 2011

- Messages

- 2,841

I have used transmission fluid before and the truck feels like it runs way harder..

This. Synthetic ATF is cheap and it lubricates well. I've never noticed a difference in power though.

I have used transmission fluid before and the truck feels like it runs way harder..

There's no "burn" efficiency to be gained from an additive.

Then why does my truck run better when i put a additive in it?

Is that what soot is? Completely burned diesel?

This all leads to the lowering of what you can call shear-stress of the fluid caused by the fuel system wall. The flow in the center of the duct we can call it will be the fastest and least amount of friction as you moved towards the wall, you see lower fluid speeds do to increasing friction between molecules, at the wall you have the most friction and lowest speed going through. Draw two lines and write the letter D and you have the basic picture of fluid flow in a pipe or gallery or whatever you choose to name it.

EDITR: Think about your frictional losses in the injector nozzle tip that could possibly be effecting your spray quality with the pressures in use.

The red fuel has not had the sulfer removed yet, find yourself a closed course and run a tank of red, and see what mpg gains you have. The list of lubricants tested that showed bio as a great additive also tested ashless 2 stroke oil, it placed 7th in the test for lubricity, however, they tested at 1/2 oz per gallon, where most of us that run it, use 1 oz per gallon.

I just bring up things most leave behind

I commend you for that! I love being provoked to think outside the box

That being said, I don't think there is any performance benefit to be realized from lowering the friction of diesel fuel.

Higher Cetane diesel does/will/can provide benefit. However, we've tested cetane effects on engine efficiency, and there is no measureable benefit above 55...and hardly any benefit above 52. The only way you can utilize a synthetic 60 cetane fuel to its potential, is to have accurate in-cylinder combustion data and tune things to the ragged edge of combustion stability/pressure rise rate/peak pressure/etc. Then, and only then, will a 60+ cetane fuel benefit you, by minimizing the variation in ignition delay that could be experienced with lower cetane fuels.

Flow enhancers, fuel magnets, aligning fuel molecules, blah blah blah, will not do anything for burn efficiency.

Even a low (40) cetane fuel still has a very high burn efficiency when it lights...it's just prone to more variation on when it lights, sometimes making it more difficult to optimize brake thermal efficiency.

Do you have access to the SAE library? If so, look up SAE Paper 2012-01-0863. It's a paper that we submitted earlier this year that gives a good characterization of fuels from 41 - 56 cetane, along with several Bio blends.

--Eric

Well I'll be! Cool sandbox you got there.

A really nasty copyright watermark is keeping me from posting a couple of graphs but.....

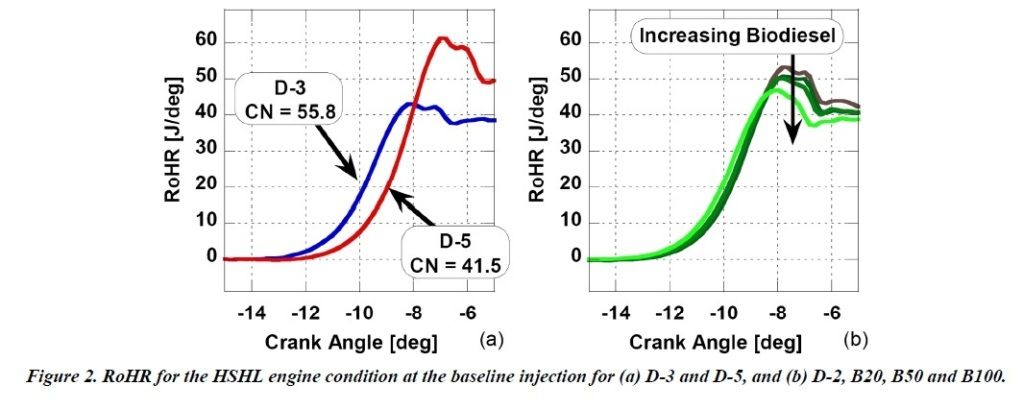

I noted a pretty significant spread in the rate of heat release between D3 and D5 and the different bioblends. Interesting data no question.

biodiesel kills the seals inside my fuel pressure sender. Not sure about how dilute with #2 it was, but Ive gone through two of them =(

Maybe I can post the graphs without the watermark here when I get a chance.

Yes, there is quite a spread in heat release. The lower cetane fuels have a lot higher initial heat release during the pre-mixed combustion event due to better vaporization (more of the charge lights off at once). For that reason, it's actually preferable to use a lower cetane fuel in some advanced combustion modes where you're looking for a sharp initial heat release. Bio blends have an advantage in the diffusion burn period, as they tend to not vaporize as readily.

The sharp heat release of lower cetane fuels can sometimes be heard, as the heat release spike causes noticeably louder combustion.

Give me a day or two heads up if you're ever coming to the Knoxville area, and I'll give you a tour of the engine labs...

Bio ate the seal out of my Isspro fuel pressure isolator too.

--Eric