You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

lockers/spools vs. welding spiders

- Thread starter lightsOUT

- Start date

dieseljunkie

Wasted Wages

- Joined

- Dec 16, 2007

- Messages

- 1,068

I still have the CAD but its current not functional due to the 271 transfer case. I could put a posi-lock cable on it, or rig something up with a vacuum source from somewhere else and a vacuum switch to make it lock and unlock.

The posi lock cable is a very inexpensive and reliable way to disconnect the front end. I welded my D60 ( nickle rod) and it seems to work great. I like the cable over the vaccume because you can feel the cable move when the collar sides in the the lock position. With the vaccume it is a guessing game.$.02

Highfinance97

Garofalo Enterprises

- Joined

- Jul 30, 2006

- Messages

- 5,135

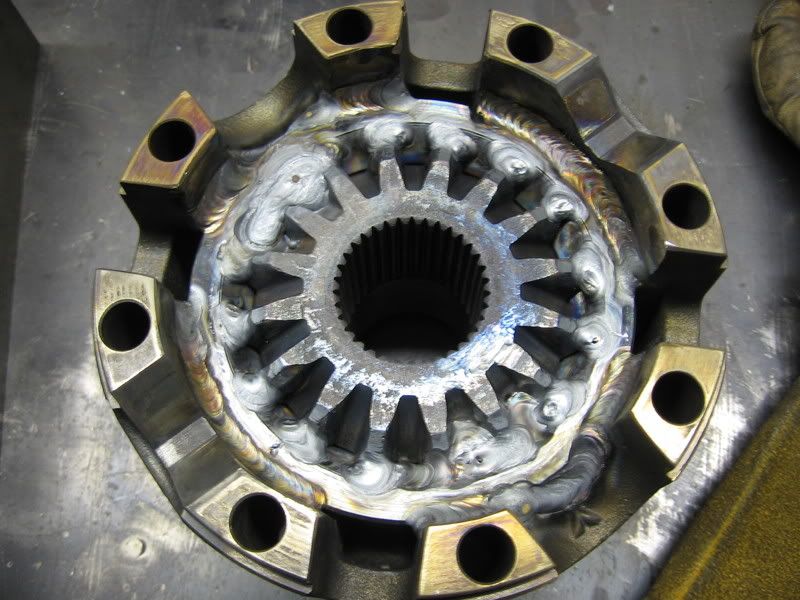

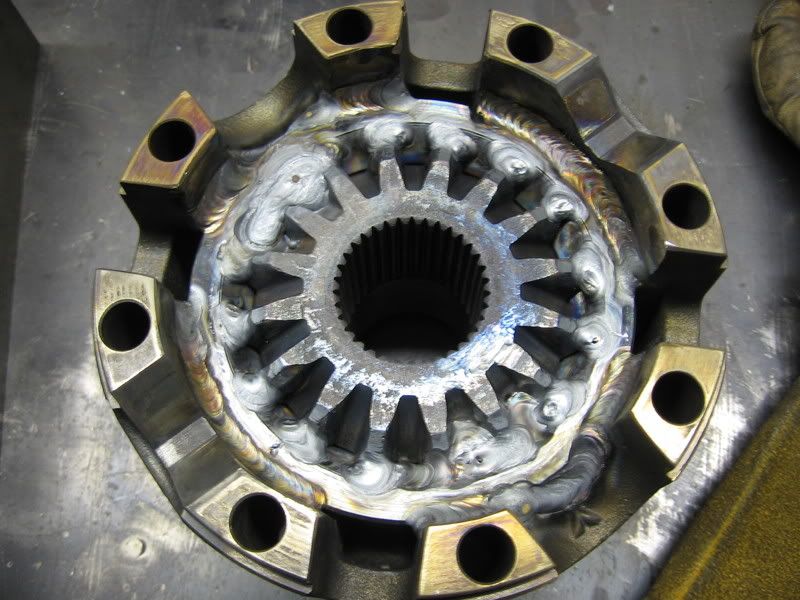

My spiders are welded and here is my rear LOL

Made a spacer on the lathe to replace the thickness of the clutches

Still holding up from 2 years ago...

Made a spacer on the lathe to replace the thickness of the clutches

Still holding up from 2 years ago...

Got Smoke?

New member

- Joined

- Oct 8, 2006

- Messages

- 4,728

Hey Michael wanna weld one up for me?! Damn!

Highfinance97

Garofalo Enterprises

- Joined

- Jul 30, 2006

- Messages

- 5,135

Hey Michael wanna weld one up for me?! Damn!

Send me your Carrier... Ill have my guy do it up for ya:rockwoot:

ORRRR I bought a spool so maybe ill sell you mine when i'm ready$.02

zstroken

For $$$ your name here

- Joined

- Sep 27, 2006

- Messages

- 23,151

Can these be welded in the truck or is it better to take the unit out to weld it? Open carrier dana 70. thanks.

Pull the carrier it is easy to pull.

Willy91

New member

- Joined

- Jan 12, 2007

- Messages

- 1,520

Pull the carrier it is easy to pull.

ok, I've never had one out, how hard is it to shim it and get the back lash back in spec? thanks. Or will it all go back together fine, just using the same shims in the same spots?

brushpuller

Thinkin...

- Joined

- Nov 30, 2008

- Messages

- 630

ok, I've never had one out, how hard is it to shim it and get the back lash back in spec? thanks. Or will it all go back together fine, just using the same shims in the same spots?

There isn't any shims on the outside of the bearings, their is a spacer,just keep them on the same sides, so as long as you don't take the bearings off the carrier...then it will go back together just like it came out! If you take the bearings off (some say to...but i never have! 99% of the time you'll mess up the bearing getting them off!) then just watch and keep the shims on the same sides!

Willy91

New member

- Joined

- Jan 12, 2007

- Messages

- 1,520

There isn't any shims on the outside of the bearings, their is a spacer,just keep them on the same sides, so as long as you don't take the bearings off the carrier...then it will go back together just like it came out! If you take the bearings off (some say to...but i never have! 99% of the time you'll mess up the bearing getting them off!) then just watch and keep the shims on the same sides!

ok don't sound to bad, thanks.

BigYellowIron

Diesel Tech

- Joined

- Aug 22, 2007

- Messages

- 1,400

Here is how I done mine. I took it apart and cleaned it all up then put it back together. Stuck it in the oven and heated it for 2 hrs at 300*. Took it out and welded it. I left the oven on and put it back in there for about a hour, then shut the oven off. I left it in there till the next day where it was cool to touch. OH I also needle peened all the welds after laying the beads.

Here are a couple pictures.

Here are a couple pictures.

brushpuller

Thinkin...

- Joined

- Nov 30, 2008

- Messages

- 630

^^^ Just to add to what your have welded...to make that stronger, weld the big side gears to the carrier also. The way it's welded now, all the stress of driving the tires is consentrated in one area around the small side gears on the carrier.

BigYellowIron

Diesel Tech

- Joined

- Aug 22, 2007

- Messages

- 1,400

I think they are....... except for the one place in the picture. I remember welding there, but I cant recall now. And the pic shows it not welded. Hell IDK.

shortbusdriver

this guy

- Joined

- May 17, 2009

- Messages

- 2,318

Thanks for the info guys, will come in handy when we start working on the bosses pulling truck this winter

lightsOUT

New member

- Joined

- Jun 1, 2006

- Messages

- 1,515

Thanks for the info guys, will come in handy when we start working on the bosses pulling truck this winter

yes, thanks. ive decided to weld both of mine.