You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ram50

- Thread starter Bodacious

- Start date

Bodacious

Comp Diesel Sponsor

- Joined

- Jul 8, 2013

- Messages

- 2,177

Making good progress! What configuration manifold did you come up with?

I just couldn't do the wait time on the steed. I may end up getting one later. I ended up getting the stainless manifold with stock 2nd gen configuration. I'll bolt on the regular way so the turbo will hang low. I will then just build the fire wall around it.

pleanty of folks will go this direction the problem has always been fitting the right convertor.

Yep, if they want to be as fast as they can be, the glide is the answer. Even with the best of the best, I still don't know if a glide could take the abuse of say 2000 lb-ft of torque at a race weight of 5000 lbs. Maybe with a 1.80 gear she would stand it??

Cummins2000

New member

- Joined

- Sep 26, 2011

- Messages

- 133

let us know what that Jetta runs in the eighth. I am pretty sure ours is the slowest car I have ever driven...

Bodacious

Comp Diesel Sponsor

- Joined

- Jul 8, 2013

- Messages

- 2,177

let us know what that Jetta runs in the eighth. I am pretty sure ours is the slowest car I have ever driven...

LOL. This little girl has 256k on 'er, Rhino line paint job, a bent rear axle, none of the door handles work, and the sloppiest shifter I've ever seen. It's gonna be a challenge to be consistent, but, this is our first visit to Schied and I just couldn't go without competing with something.

Being 1/8th mile, I'd say she'll come in at a blistering 16. something. I'll let you know.

Bodacious

Comp Diesel Sponsor

- Joined

- Jul 8, 2013

- Messages

- 2,177

I asked Taylor with Manning Motorsports about that. He said no customization was available.

We made it back from SDX alive. The Jetta ran consistent 14.4's but the driver was not on his game. My son decided to race his 1st gen and smoked the clutch to the point it wouldn't move. We loaded his truck in the race trailer and he drove the little Jetta the 8 hr trip back to the house.

We made it back from SDX alive. The Jetta ran consistent 14.4's but the driver was not on his game. My son decided to race his 1st gen and smoked the clutch to the point it wouldn't move. We loaded his truck in the race trailer and he drove the little Jetta the 8 hr trip back to the house.

Bodacious

Comp Diesel Sponsor

- Joined

- Jul 8, 2013

- Messages

- 2,177

Hey JQ, it was nice meeting you as well. I appreciate the time you spent with us letting me pick your brain. Yea, the sides of the trailer bowed out just a bit when we squeezed 'er through the door. When the back of the bed made it into the trailer, the sides straightened right up. lol. I'd say we were somewhere near 20k gross and the wife's '09 handled it amazingly great even with the 37's. My old '90 model would have handled it fine, but, I would have been fighting egt's once we got back into WV. I think I've talked the boy into building me some compounds like he has. Yea HA!!!

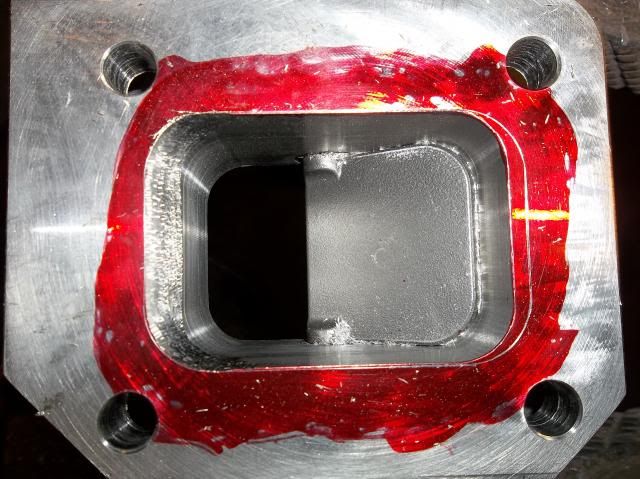

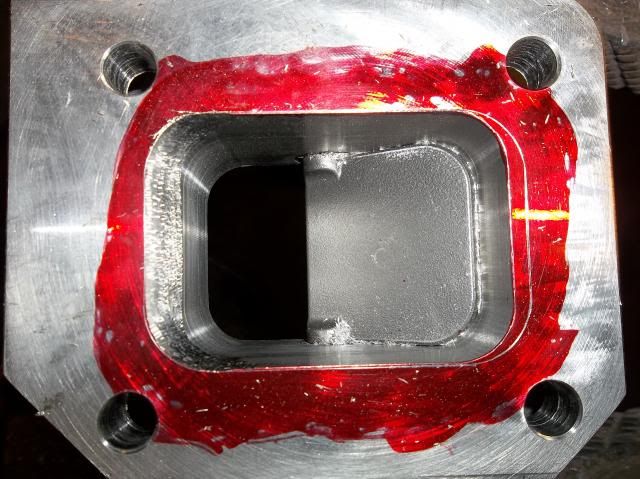

I took delivery of my stainless diesel manifold yesterday and had some time today to mess with it. I was surprised at how heavy this thing is or was. The initial opening matches the gaskets well, but, they have about a 45 degree taper going into the manifold. our head is gasket ported so I figured I'd better get the die grinder out and get busy. I hope I didn't mess it up.

I had to break out the big boy air for this job. She's an Airman 185 I bought several years ago. It has the 2.0 Isuzu diesel and runs great. It was totaled from a roll over when we picked it up. On a job like this, you never have to wait on air and it really saves the 'ol shop compressor.

I'd say I cut a good 2 lbs off the manifold. The pile of sharpies laying in the floor and stuck in my clothes will attest.

I took delivery of my stainless diesel manifold yesterday and had some time today to mess with it. I was surprised at how heavy this thing is or was. The initial opening matches the gaskets well, but, they have about a 45 degree taper going into the manifold. our head is gasket ported so I figured I'd better get the die grinder out and get busy. I hope I didn't mess it up.

I had to break out the big boy air for this job. She's an Airman 185 I bought several years ago. It has the 2.0 Isuzu diesel and runs great. It was totaled from a roll over when we picked it up. On a job like this, you never have to wait on air and it really saves the 'ol shop compressor.

I'd say I cut a good 2 lbs off the manifold. The pile of sharpies laying in the floor and stuck in my clothes will attest.

Last edited:

Bodacious

Comp Diesel Sponsor

- Joined

- Jul 8, 2013

- Messages

- 2,177

Had some time today to play a little on the race ride. We bolted on the stainless diesel manifold and bent out the down bars to the rear frame rails.

With the down bars bent and cut to fit, we can now remove the cab and take all the body to the paint shop.

With the down bars bent and cut to fit, we can now remove the cab and take all the body to the paint shop.

Bodacious

Comp Diesel Sponsor

- Joined

- Jul 8, 2013

- Messages

- 2,177

The bottom bar on the ladder bar is parallel with the frame. This is typical and will more than likely never change. I never understood the purpose of the three hole brackets as a change this extreme on the front of the bars is not practical. The upper hole would put so much bite in the chassis, she'd unload shortly after initial launch. The bottom hole would make the thing extremely loose. I bought the brackets and mounting bar thinking I needed the bar for the cross member. I ended up using a straight piece of chrome moly and the brackets. I should have just fab'd my own brackets cause we will more than likely cut the top and bottom holes off.

Bodacious

Comp Diesel Sponsor

- Joined

- Jul 8, 2013

- Messages

- 2,177

I've been running some calculations and would like some opinions on which rear gear to start with. I have already purchased the moser center section with 3.0 gears, but, the gears are street gears. My original HP figures are out and I'm sorta looking to the 1,000HP mark now. Also, hitting those gears with a trans brake at 3,000lbs will be brutal.

Calculating everything out with no converter slip, she'd be running 172 MPH at 5,000 RPM's. I don't want to be in this thing going that fast, EVER, so I was thinking maybe dropping to a 3.40 ratio. Richmond builds a pro gear in this ratio and still would crank out at 155 MPH. This is still way faster than I'd care to go and real world physics won't let it happen anyway. I probably won't run any 1/4 mile stuff unless she's way slow. I also have the 1.57 first gear in the glide which should load the engine nicely once the trans brake is released.

I'm thinking the 3.40 would be my best bet????

Calculating everything out with no converter slip, she'd be running 172 MPH at 5,000 RPM's. I don't want to be in this thing going that fast, EVER, so I was thinking maybe dropping to a 3.40 ratio. Richmond builds a pro gear in this ratio and still would crank out at 155 MPH. This is still way faster than I'd care to go and real world physics won't let it happen anyway. I probably won't run any 1/4 mile stuff unless she's way slow. I also have the 1.57 first gear in the glide which should load the engine nicely once the trans brake is released.

I'm thinking the 3.40 would be my best bet????

r-rated diesel

New member

- Joined

- Oct 6, 2011

- Messages

- 1,345

Wow man i'm pretty sure that is the coolest thing ive ever seen! Please keep the updates coming!

r-rated diesel

New member

- Joined

- Oct 6, 2011

- Messages

- 1,345

But Im not sure about the solid motor mounts..

Bodacious

Comp Diesel Sponsor

- Joined

- Jul 8, 2013

- Messages

- 2,177

Wow man i'm pretty sure that is the coolest thing ive ever seen! Please keep the updates coming!

Thanks!!!

But Im not sure about the solid motor mounts..

Yea, it's gonna shake a bit, but, now the engine is an integral part of the chassis or will be when I get the mid plate installed.

Bodacious

Comp Diesel Sponsor

- Joined

- Jul 8, 2013

- Messages

- 2,177

EEEEEEEEEK, look out Ethel. It's done to late... she's done been mooned!!!

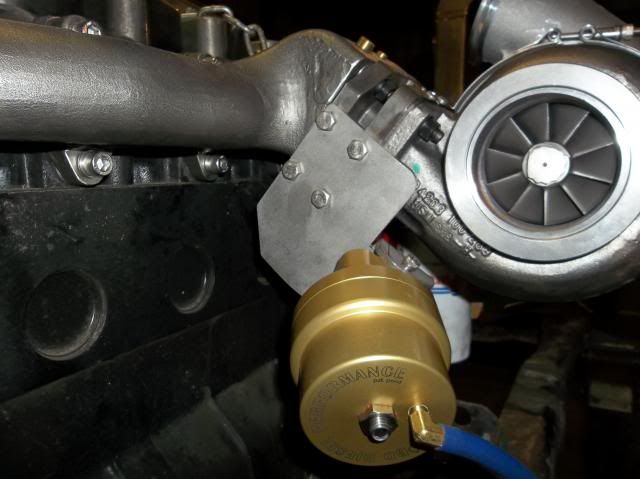

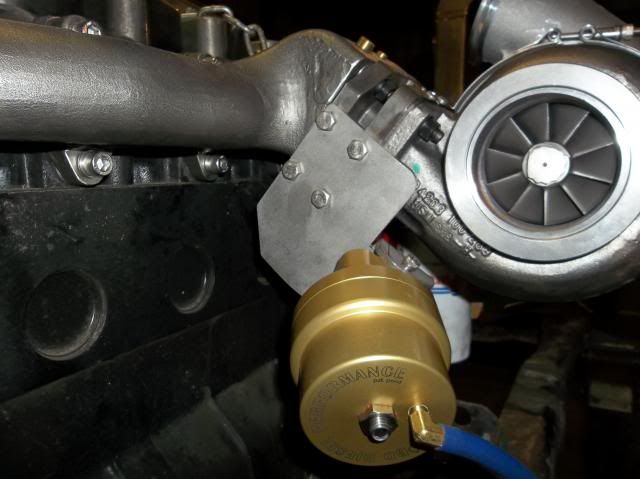

Body parts are at the paint shop. Took the diverter valve and gasket matched the inlet so the exhaust wouldn't be crashing into the 3/16 inch wall jutting out.

Looks like the exhaust gas should pass along nice and smooth now.

I didn't cut any on the outlet of the diverter valve. It was just a little under 1/8 inch from matching the S480 turbo inlet and I didn't feel the need to gasket match both pieces.

Turbo and diverter valve bolted on. Don't know how fast she'll be, but, it is definitely starting to look fast.

If any diverter valve veterans are reading, what PSI should I set the valve to open on initial start up?

Body parts are at the paint shop. Took the diverter valve and gasket matched the inlet so the exhaust wouldn't be crashing into the 3/16 inch wall jutting out.

Looks like the exhaust gas should pass along nice and smooth now.

I didn't cut any on the outlet of the diverter valve. It was just a little under 1/8 inch from matching the S480 turbo inlet and I didn't feel the need to gasket match both pieces.

Turbo and diverter valve bolted on. Don't know how fast she'll be, but, it is definitely starting to look fast.

If any diverter valve veterans are reading, what PSI should I set the valve to open on initial start up?

Bodacious

Comp Diesel Sponsor

- Joined

- Jul 8, 2013

- Messages

- 2,177

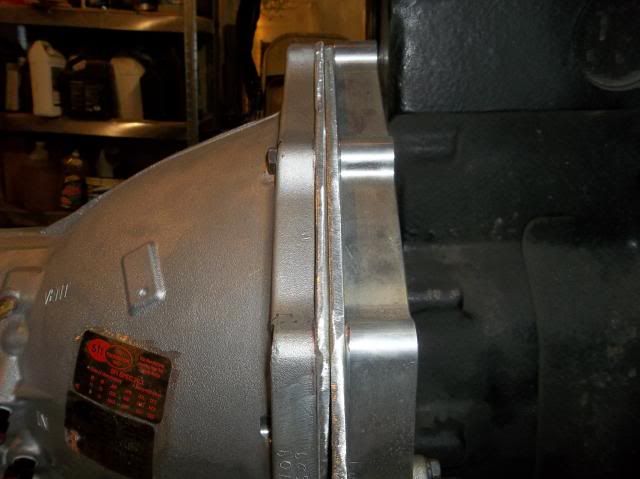

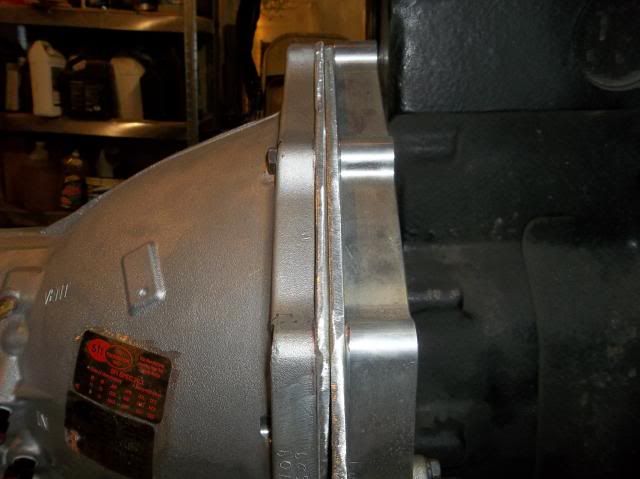

...got tranny installed today. We used a 1/4" mid plate plus we built another 1/4" spacer out of the left over material after I trimmed down the mid plate. I had my son tig all the pieces together although it would not have been necessary. Once I fully seated the converter, We bolted on the tranny and the converter spun freely. Here it is complete with 2001 Powerstroke starter. She'll really get with it now that it is 'Ford'ified. LOL

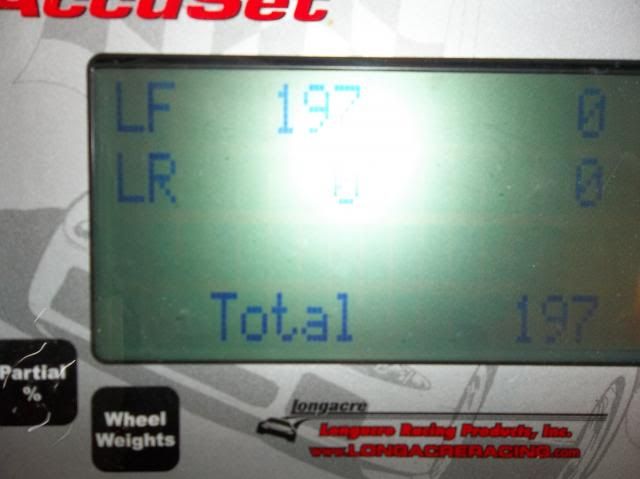

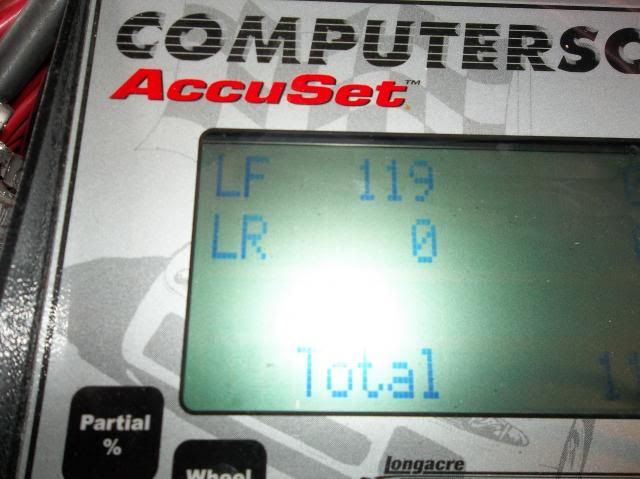

My son is in the process of installing a semi-built 47rh into his first gen and we had both trannys laying there on the floor. So, we took the time and weighed the two. Here are the results.

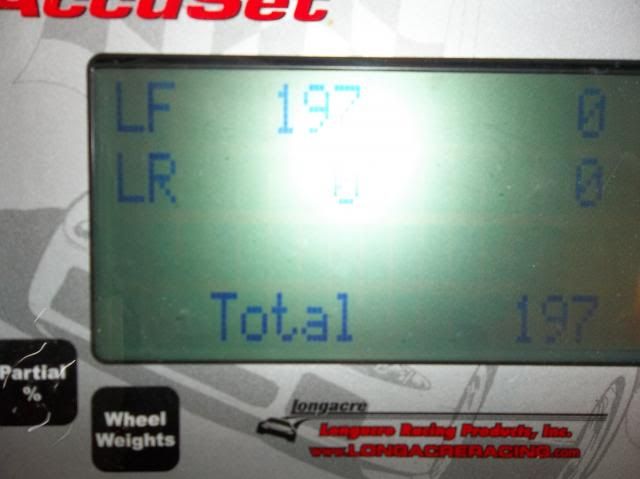

The 47rh:

The scale reads 197 if the glare is too bad.

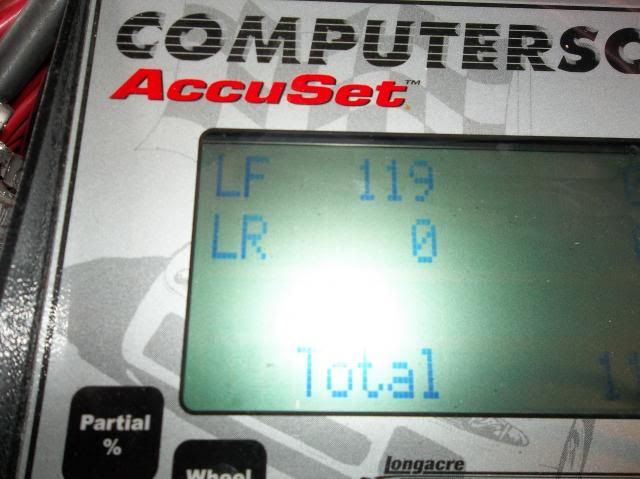

The fully built powerglide that will withstand 2500HP

Roughly 78lbs difference. The powerglide was ran on a dyno so it has some traces of fluid weight. The 47rh is dry.

I wanted to go ahead and throw one last pic on here, my son is on a little tighter budget than myself. So, when we read on here about the flexplates cracking, we hunted up a billet flexplate at $450. Instead of buying the billet, we cut down an old plate from an A518 we had laying around and welded it to the other complete flexplate. Were not sure it will work, but, sometimes you just gotta try???

My son is in the process of installing a semi-built 47rh into his first gen and we had both trannys laying there on the floor. So, we took the time and weighed the two. Here are the results.

The 47rh:

The scale reads 197 if the glare is too bad.

The fully built powerglide that will withstand 2500HP

Roughly 78lbs difference. The powerglide was ran on a dyno so it has some traces of fluid weight. The 47rh is dry.

I wanted to go ahead and throw one last pic on here, my son is on a little tighter budget than myself. So, when we read on here about the flexplates cracking, we hunted up a billet flexplate at $450. Instead of buying the billet, we cut down an old plate from an A518 we had laying around and welded it to the other complete flexplate. Were not sure it will work, but, sometimes you just gotta try???

12vriviera

That Guy with that car

- Joined

- Mar 31, 2009

- Messages

- 6,846

I used an insert, magically a stock flex plate with the outer ring cut off, then sets inside the stocker, makes it "laminated"and takes punishment.

4x4manonbroke

Diesel Monster

- Joined

- Aug 20, 2013

- Messages

- 278

cbtoyz, the truck tranny is a little on the heavy side, but, that's not a major issue. What I'm after with the glide is the first gear ratio. I don't think I could get a tall enough diff gear to do it with a truck tranny. With the glide, I'll be at (1.80x3.0) 5.40. I had even considered a stock 1.76 first gear until I learned they would never hold. Additionally, I'm not running enough wheel brake to hold back that sort of power so I'll need to leave on a trans brake.

DEZLFREK, I wish we had started with 215 pump. I'm gonna get a custom cam with 13mm plungers. I got the price the other day for the work and parts and I'm gonna go ahead with it. This fella has done 3 VE's for me and they were all great. So, now I know I'll have the fuel and RPM's.

If this was your engine and you wanted to get where I need to be HP wise, what would you run for turbos? I was thinking the HT3B wouldn't be enough, but we have it already. Our cam is the 220/240. I was thinking s300/s400 combo??????? Everyone with helpful info please jump in here. We don't know much about turbos.

jamesl. Would you care to find out what bell housing he's running for me? I spoke to JW today and they also told me to run a thick mid plate and it would work. This is terrific news. Looks like it is possible.

slammed1500ssc & others, we sorta went through a big plan change today. The street slicks and rims are no longer for sale. I took delivery of my moser rear and threw the little housing up on the back and started doing some thinking. (finally lol) We are absolutely going to be beating on this thing in the sand and mud as well as street driving. If it were drag only, I might still consider the narrowed rear. However, after considering the lack of stability this thing would have with such a narrow housing (leaf springs would only be 20" apart), we've decided to go with a full width housing and hack on the fender openings just a little. Anyone need a housing and axles? ($800 for both brand new)

So, this will be the permanent drag look. We are hoping now that the 13.50's will bite good enough. We are also going to sling the rear housing underneath the rear springs to gain about 3.5" of lift. I've got it jacked up in the rear in these pictures to emulate the lift. I've got some 4-corner scales coming soon to see how she's going to weigh out.

man this thing looks like it will launch nice .... almost a Gasser look goin on here ...... been thinking about a move to the east coast ... y'all have diesel running through ur veins like me ..... I think its time to pack up and move out *nx*