You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solid Billet 5.9 Block

- Thread starter RacinDuallie

- Start date

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

You’re talking about Steve Lowe at LSM and they are basically the Pro Stock skunk works for all of the Pro Stock Teams on either side of the brand wars. I talked to Steve about his block 3 years ago, and it was bullet proof, but way too heavy for drag racing. I have been dealing with them for 10 plus years selling them G.M. Performance parts Raw Pro Stock, DRCE II, III and short deck comp block for most of the engine programs out there. These are the real inside type people, I would venture that 99 % of all good billet cam cores originate in their shop. If you get thru to Steve , be very ready to quickly explain what you need , what your going to do with it , and where is you wheel barrow of money going to come in to their door. On the other hand Steve Jr is a little more sympathetic to the diesel world

Holeshot

Diesel Sherpa

- Joined

- Apr 24, 2006

- Messages

- 74

Jff24Gordn said:There is a alumnium 5.9. It came with a P pump. I have seen it. I think they said it saved about 80 lbs or something like that.

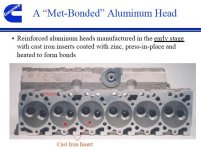

There was also an aluminum head put together with steel inserts...

I have it in a .pdf entitled "The Influence of Light Weight Materials on Fuel Economy and Emissions in Heavy Duty Diesel Engine"

Paul C. Becker, Yong-Ching Chen and Martin Myers: Cummins Inc. 8/20 - 8/24/2000. This was a presentation at the DEER Workshop in San Diego, CA.

Here are some points from the doc:

For an in-line six cylinder diesel engine:

A total 25% reduction in total engine weight

6% reduction in fuel consumption

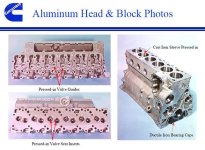

Head and block cast in aluminum using 1988 vintage tooling

Cylinder liner, valve guides and valve seats are pressed-in rebuild kit components

Main bearing cap is ductile cast iron production part

Cast iron engine weighs 880 lbs.

Aluminum engine weighs 668 lbs.

Weight Saving is : Head: 70 lbs.

Block: 140 lbs.

Total: 210 lbs. (24%)

Engine achieved max. torque of 712 ft-lb. @ 1400 rpm and

240 hp @ 2500 rpm

Noise test indicated that the engine was similar to cast iron at

full load, but was slightly higher at half and no load

conditions

Completed 500 hours of thermal cycle test. Engine was shut down due to a severe coolant leakage

Built up one aluminum engine for NAVY for noise &

magnetic signature measurements

Later,

Matt

Attachments

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,369

Holeshot said:There was also an aluminum head put together with steel inserts...

I have it in a .pdf entitled "The Influence of Light Weight Materials on Fuel Economy and Emissions in Heavy Duty Diesel Engine"

Paul C. Becker, Yong-Ching Chen and Martin Myers: Cummins Inc. 8/20 - 8/24/2000. This was a presentation at the DEER Workshop in San Diego, CA.

Here are some points from the doc:

For an in-line six cylinder diesel engine:

A total 25% reduction in total engine weight

6% reduction in fuel consumption

Head and block cast in aluminum using 1988 vintage tooling

Cylinder liner, valve guides and valve seats are pressed-in rebuild kit components

Main bearing cap is ductile cast iron production part

Cast iron engine weighs 880 lbs.

Aluminum engine weighs 668 lbs.

Weight Saving is : Head: 70 lbs.

Block: 140 lbs.

Total: 210 lbs. (24%)

Engine achieved max. torque of 712 ft-lb. @ 1400 rpm and

240 hp @ 2500 rpm

Noise test indicated that the engine was similar to cast iron at

full load, but was slightly higher at half and no load

conditions

Completed 500 hours of thermal cycle test. Engine was shut down due to a severe coolant leakage

Built up one aluminum engine for NAVY for noise &

magnetic signature measurements

Later,

Matt

Good lord!!!

Attachments

Signature600

THA MAN!

- Joined

- Aug 5, 2006

- Messages

- 11,995

Is that smiley doing what I think he's doing???

That's so wrong...but SO funny

Chris

That's so wrong...but SO funny

Chris

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,369

Paper towels in isle 3.....

Burner

slow poke

- Joined

- Apr 24, 2006

- Messages

- 4,393

Signature600 said:Is that smiley doing what I think he's doing???

That's so wrong...but SO funny

Chris

I agree!!! Scratch'n his foot, what a riot! :hehe:

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,369

Burner said:I agree!!! Scratch'n his foot, what a riot! :hehe:

Please......... leave me alone for a few with this aluminum block and head...............

:hump: :hehe: :hehe: :hehe:

Distributor

Diesel Doctor

- Joined

- Aug 20, 2006

- Messages

- 314

A billet block is only as good as the people that are having it made. From the pics I have seen you would have thought they would have made some changes like cam location,main brg caps etc

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

why mess with a Cummins if you going to do a billet block, take a Top fuel block and a head similar to the 5.00 BS Chevy hemi head , put a pair of Duramax injectors in it and you have the making of a 800 cid engine that will spin 6000 and make 2000 hp

Last edited:

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

Want one , I can make it happen , , just part of doing what I do best , this is part of why I’m in the positions I have been in the past , I can make a billet block happen , custom heads no problem , . I would guess that most think that with money anything can happen, but its knowledge and connections that make this stuff happen, I have given it on here openly and freely, and sometimes it’s laughed at, example REV GAIN.

I would point to the video on Joe Farmers My space, on the 8.62 pass, turn the volume up and listen to what a 6000 RPM Cummins sounds like as it make a smokeless pass, screaming down the track smoke on the starting line was from a stuck open waste gate

http://vids.myspace.com/index.cfm?fuseaction=vids.individual&videoid=1447533521

The world of diesel drag racing is in its infancy, and the technological level is just starting to take off. As in Drag racing 30 years ago it became apparent that people with innovative ideals, and the ability to make it happen were from outside the sport, so is it in diesel.

If some one wants some direction and some of the innovative parts that people start a thread like this about and fantasize about, no problem if you really want it, no problem, be serious and it can be produced. How many and when, and where is the check

By the way the Cummins version of that block is available for about $15,000 and weighs 140 lbs lighter then a Cummins cast iron block, it has 60 mm roller cam bearings , 4.320 Niciseal bores , Jessel keyed roller lifters a shorter deck, and revised oiling. No water, and 9/16 head and cross bolted mains its lives on a CD and with a check can be in your living room floor in 6 months if someone chose to let it out.

This is directed at internet peckers and wantabees . not the many people that I talk to daily and don’t really mind helping

I would point to the video on Joe Farmers My space, on the 8.62 pass, turn the volume up and listen to what a 6000 RPM Cummins sounds like as it make a smokeless pass, screaming down the track smoke on the starting line was from a stuck open waste gate

http://vids.myspace.com/index.cfm?fuseaction=vids.individual&videoid=1447533521

The world of diesel drag racing is in its infancy, and the technological level is just starting to take off. As in Drag racing 30 years ago it became apparent that people with innovative ideals, and the ability to make it happen were from outside the sport, so is it in diesel.

If some one wants some direction and some of the innovative parts that people start a thread like this about and fantasize about, no problem if you really want it, no problem, be serious and it can be produced. How many and when, and where is the check

By the way the Cummins version of that block is available for about $15,000 and weighs 140 lbs lighter then a Cummins cast iron block, it has 60 mm roller cam bearings , 4.320 Niciseal bores , Jessel keyed roller lifters a shorter deck, and revised oiling. No water, and 9/16 head and cross bolted mains its lives on a CD and with a check can be in your living room floor in 6 months if someone chose to let it out.

This is directed at internet peckers and wantabees . not the many people that I talk to daily and don’t really mind helping

Distributor

Diesel Doctor

- Joined

- Aug 20, 2006

- Messages

- 314

Comp

No need in "you" making a billet 5.9 block happen, It has been done for months.....

IMHO It needs to be redone, instead of making it a carbon copy of a stock block tho.

No need in "you" making a billet 5.9 block happen, It has been done for months.....

IMHO It needs to be redone, instead of making it a carbon copy of a stock block tho.

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

It’s been done for years from LSM, saw it two years ago at the PRI show, but it was steel and heavy.

The one I have been involved with for the last few years is nothing like a Cummins block, its aluminum, big 60 mm cam core, cross bolt block and weighs 137 lbs with a Chevy bolt pattern, and Jessel belt drive. The pump is driven on the front on the block also. This project was to have been a common Rail. The only similarity in it and a Cummins block is the head bolt pattern. It look similar to a Cummins for recognition, But that is about it. Its now resides on a CD; its lead time is 6 months to order the billet of aluminum .

The one I have been involved with for the last few years is nothing like a Cummins block, its aluminum, big 60 mm cam core, cross bolt block and weighs 137 lbs with a Chevy bolt pattern, and Jessel belt drive. The pump is driven on the front on the block also. This project was to have been a common Rail. The only similarity in it and a Cummins block is the head bolt pattern. It look similar to a Cummins for recognition, But that is about it. Its now resides on a CD; its lead time is 6 months to order the billet of aluminum .