BC847

Member

- Joined

- May 14, 2006

- Messages

- 851

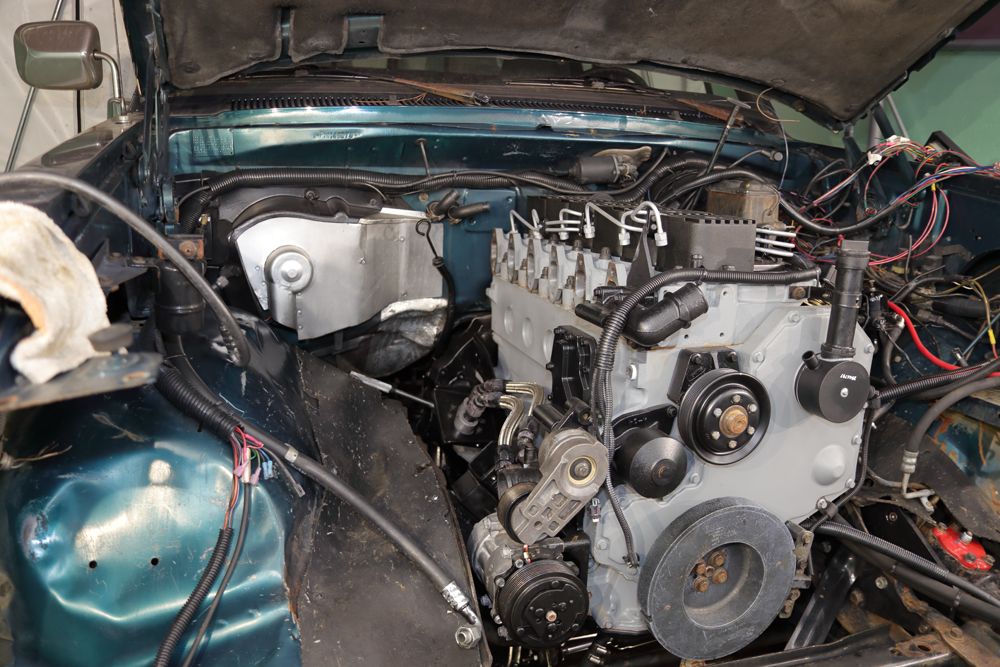

Cleaned the skank engine-bay and started sorting wires and hoses. Removed the Water/Methanol stuff.

Back when I installed the 49RH transmission, I learned Dodge didn't include room for transmission bell-housing bolts of a 49RH to go in/come out with the cab in place. Tilted or not. I was reminded when I pulled the failed engine.

- I took the opportunity to "Make Room" by removing/folding-over sections of the cab's pinch-welds right there behind/above where the top two bell-housing bolts need room for dis-/assembly. (Shown with the transmission drooping big-time).

Got those pesky little parts to tie-up loose-ends like the now unused water/methanol injector port getting a plug (the 2nd of the two is a charge-air temperature sensor now). A plug for the unused KSB's temperature sensor port in the intake-log's cover-plate. REAL Silicone-lined hose to best accommodate those hot turbo lube-oil drain connections to the pan/block. Refined the VE's fuel return banjo fitting/line by replacing the OEM fitting with one that immediately transitions to -4AN. Crap like that.

I'm at the point I think everything's ready to set the simple long-block into the truck.

Back when I installed the 49RH transmission, I learned Dodge didn't include room for transmission bell-housing bolts of a 49RH to go in/come out with the cab in place. Tilted or not. I was reminded when I pulled the failed engine.

- I took the opportunity to "Make Room" by removing/folding-over sections of the cab's pinch-welds right there behind/above where the top two bell-housing bolts need room for dis-/assembly. (Shown with the transmission drooping big-time).

Got those pesky little parts to tie-up loose-ends like the now unused water/methanol injector port getting a plug (the 2nd of the two is a charge-air temperature sensor now). A plug for the unused KSB's temperature sensor port in the intake-log's cover-plate. REAL Silicone-lined hose to best accommodate those hot turbo lube-oil drain connections to the pan/block. Refined the VE's fuel return banjo fitting/line by replacing the OEM fitting with one that immediately transitions to -4AN. Crap like that.

I'm at the point I think everything's ready to set the simple long-block into the truck.

.jpg?width=1920&height=1080&fit=bounds)