Chevycummins

Bad case of Tinkeritis!

- Joined

- Jul 15, 2008

- Messages

- 3,488

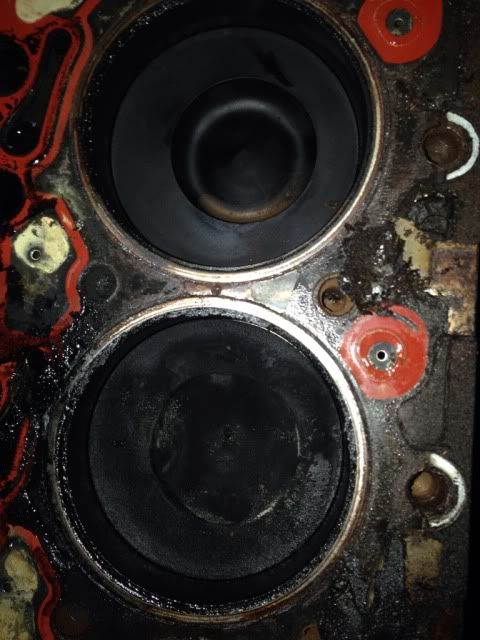

I started blowing white startup smoke after towing a 8000# toyhauler to colorado. Then by the time I got back home, I had oil blowing out of my dipstick tube. Turbo is ok, but Im thinking a injector might have washed a cylinder.. rings failed as I see light scoring.

If you are the same I seen on another forum, 6bt in an E350, you found a great spot for a wealth of info on these engines. Get a good rebuild kit and get it back together and get that egt probe in the right spot.

There isn't a whole lot of specialty tools required for these engines. Pretty simple to build too