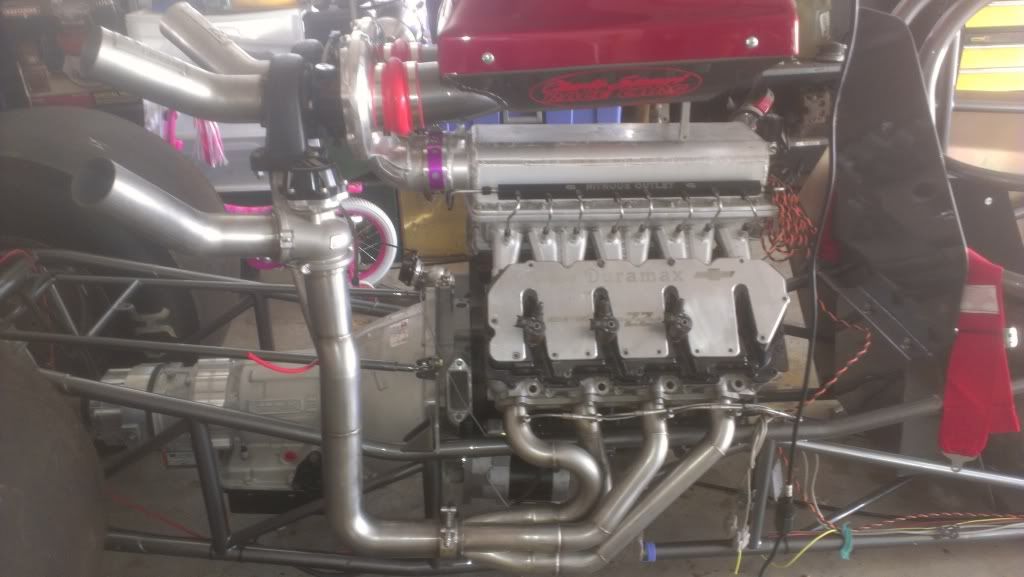

COMP461

Comp Diesel Sponsor

I will when it look presentable. Had to buy a -12 tape for my dry sump fittings in the pan.

Looks like I may retire from the fire department after 26 years to go and race this car full time. G.M. wants me to run 15 to 20 events. I like the IHRA format the best 2 races in the same weekend. You get 2 time trials on Friday and then and additional time trial Saturday and Sunday morning. Then you race a point’s race.

NHRA divisional may go to the same format because of the price of fuel. NHRA nationals are long and drawn out 1 time trial on Thursday, 2 on Friday and first round on Saturday. Big reason why I’m taking my tim e to get this right, it has to run in the low 7’s and high 6’s to get qualified, and then consistent to be there on Sunday.

Looks like I may retire from the fire department after 26 years to go and race this car full time. G.M. wants me to run 15 to 20 events. I like the IHRA format the best 2 races in the same weekend. You get 2 time trials on Friday and then and additional time trial Saturday and Sunday morning. Then you race a point’s race.

NHRA divisional may go to the same format because of the price of fuel. NHRA nationals are long and drawn out 1 time trial on Thursday, 2 on Friday and first round on Saturday. Big reason why I’m taking my tim e to get this right, it has to run in the low 7’s and high 6’s to get qualified, and then consistent to be there on Sunday.