dangerous06

diesel tech

Can anyone point me to a thread that discussed pro's and con's on best spray pattern angle versus 5 hole or 8 hole?! If the guru's would please post up the test results and conclusions I WOULD really appreciate it!

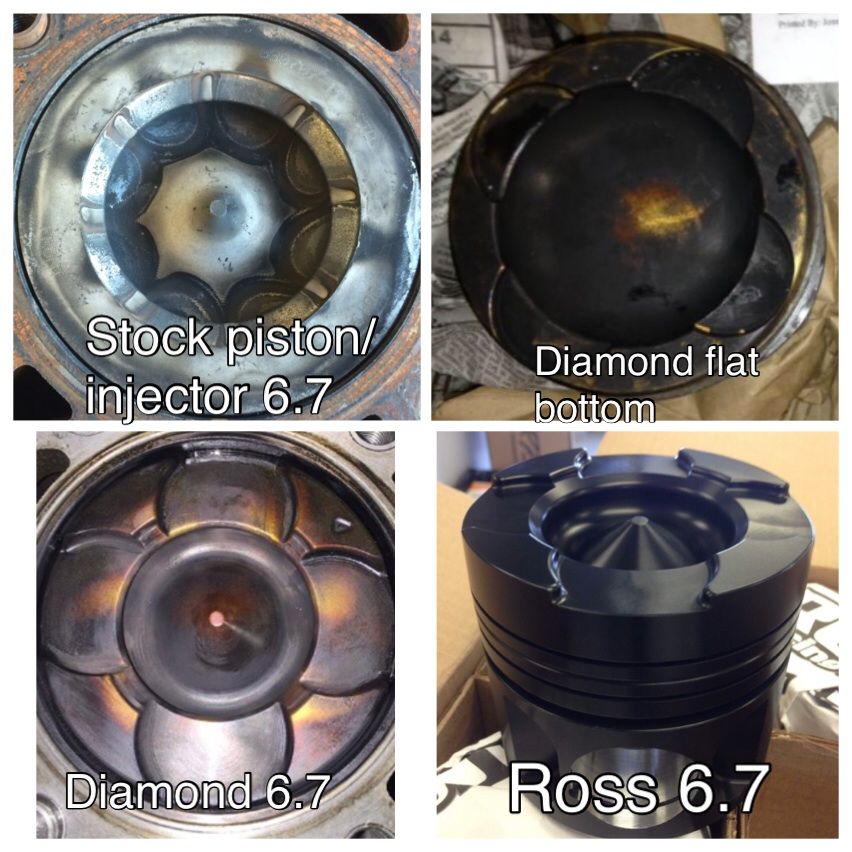

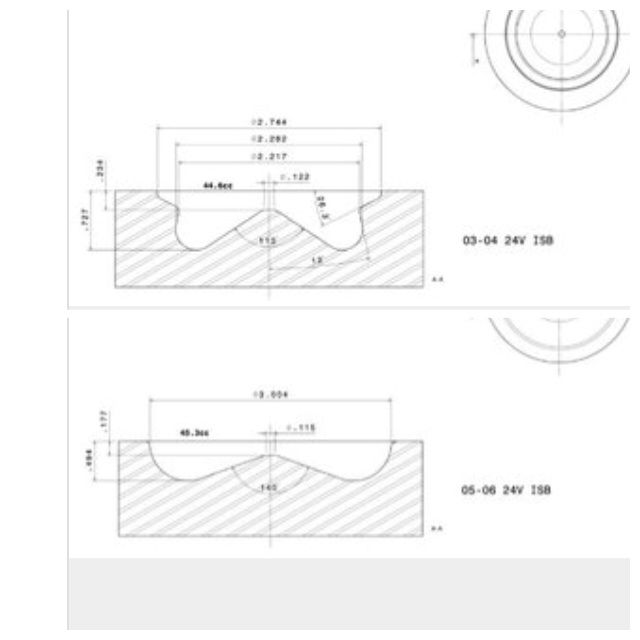

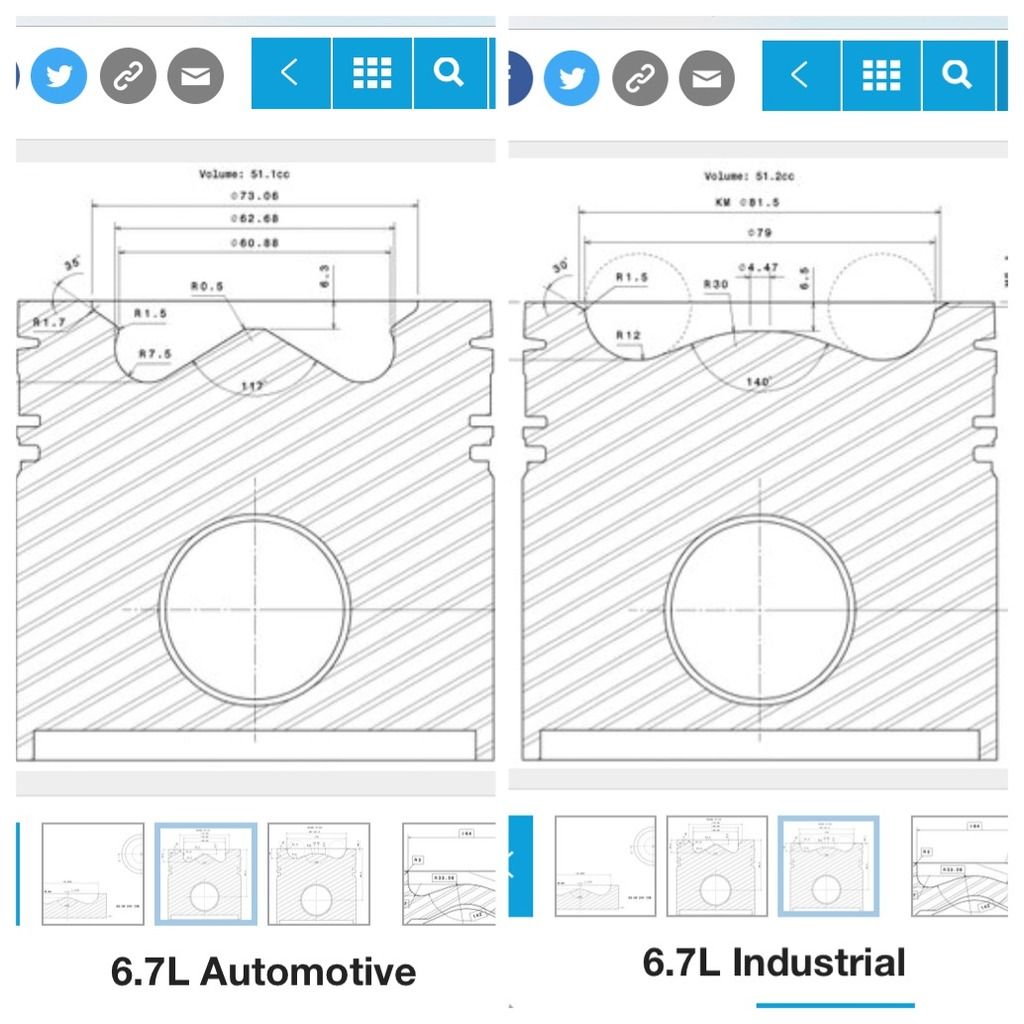

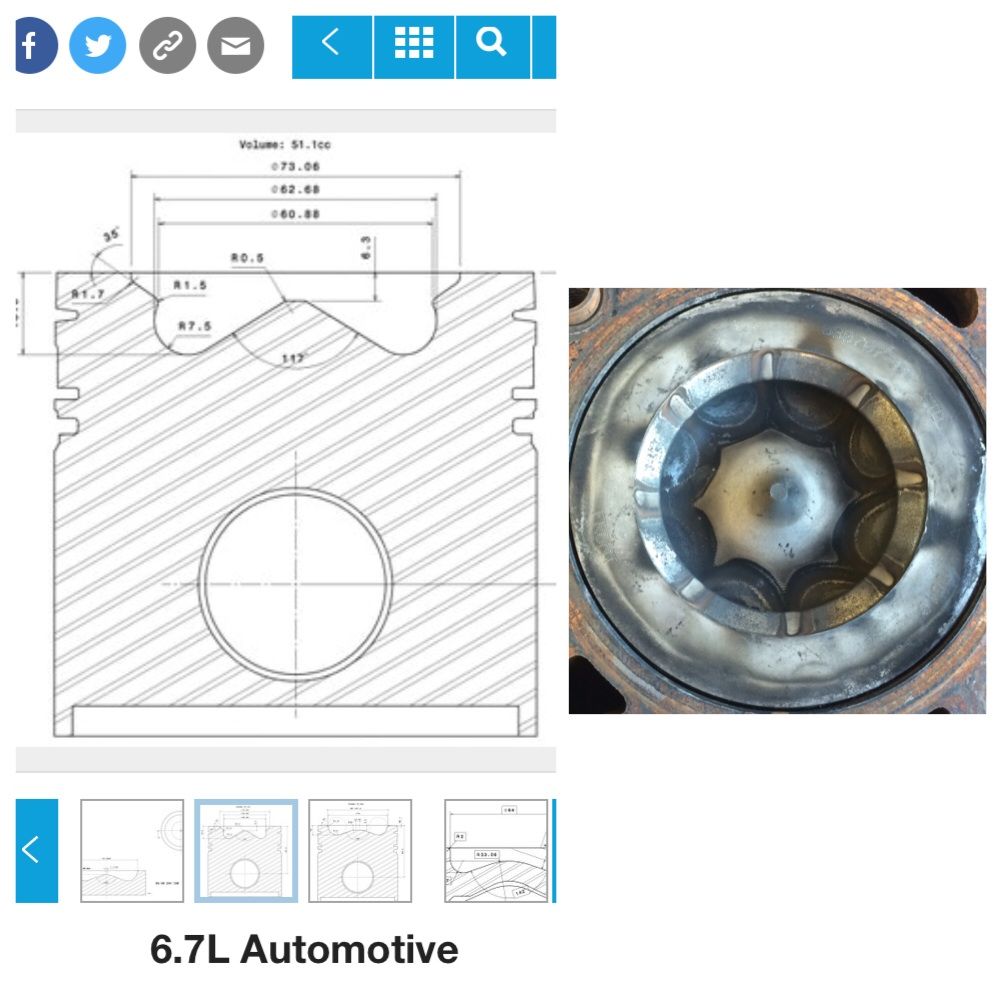

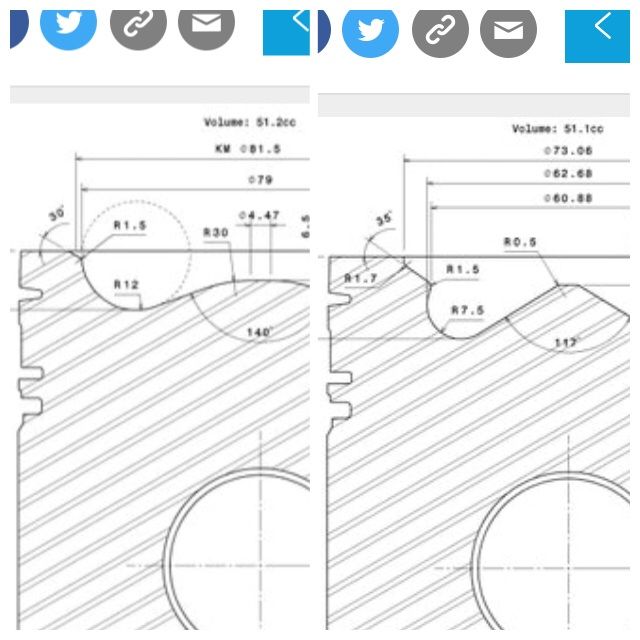

Reason for thread is deciding on which bowl type and injector style to run in a 6.4 build Both early 04 and later 04.5 07 types are available for the 6.7.

Reason for thread is deciding on which bowl type and injector style to run in a 6.4 build Both early 04 and later 04.5 07 types are available for the 6.7.