John Robinson

New member

I am looking to build a set of triples for a project. Im planning at a divorced exhaust manifold setup that will have 2 small secondarys going to the primary. Target hp is 1000 hp . Instant spoolup is what we are looking for & we will still run an intercooler.

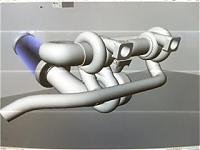

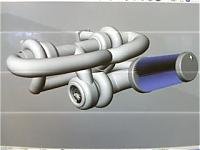

What chargers do yall think i should run? I am not a turbo engineer . I figured i would throw it out to the big brains on here & see what would come of it. Here are some pics of a setup that i think look really clean & easy

What chargers do yall think i should run? I am not a turbo engineer . I figured i would throw it out to the big brains on here & see what would come of it. Here are some pics of a setup that i think look really clean & easy