You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1967 RS Duramax Camaro

- Thread starter dslhtrdr

- Start date

dslhtrdr

Always learning...

- Joined

- Sep 2, 2009

- Messages

- 677

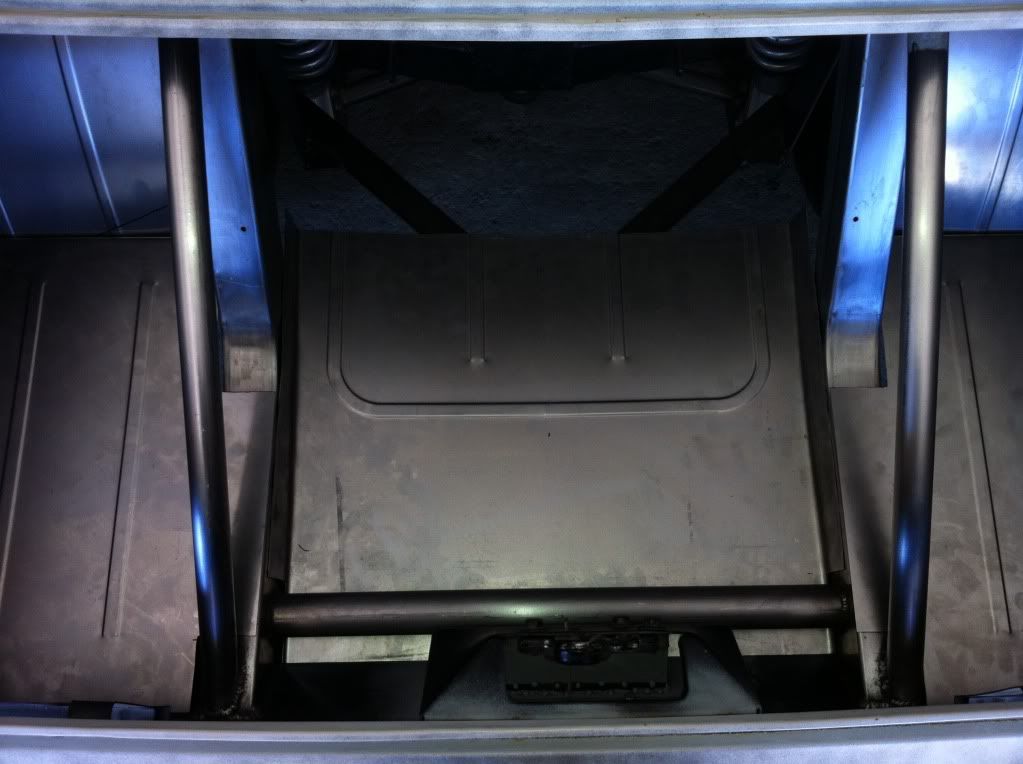

I used some sheet metal screws to temporarily attach them while I made the rest of the trunk floor.

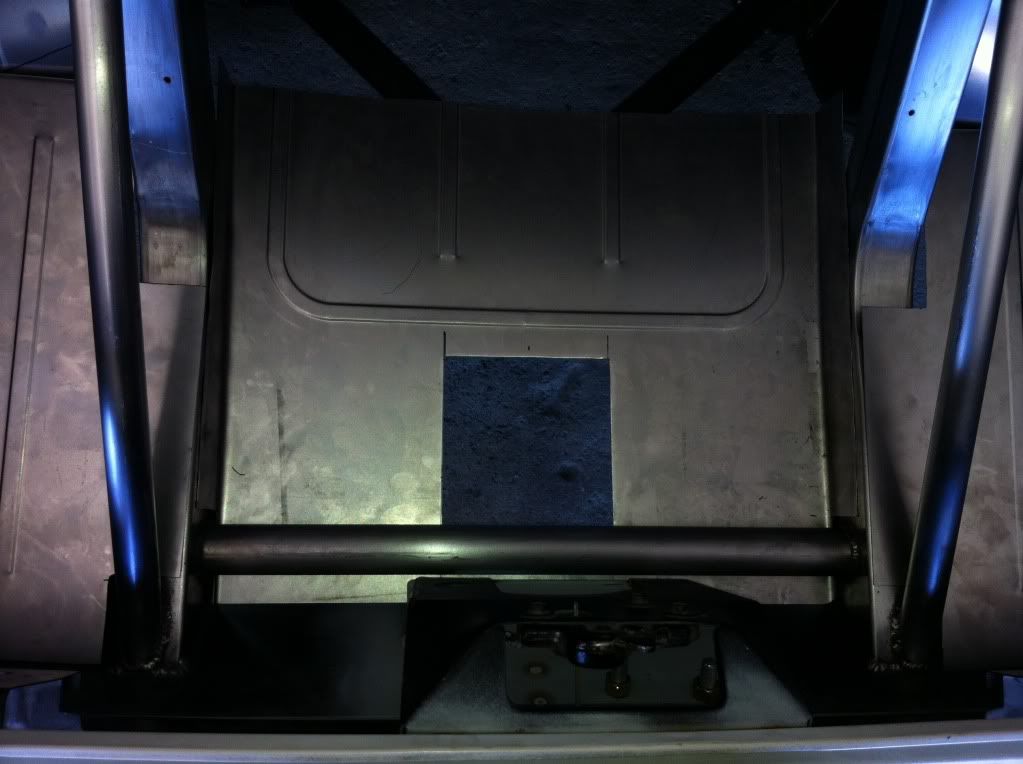

I also got the floor kit from Chassisworks. It needs to be trimmed and fit to the frame and car, and notched for all the roll cage tubing.

I also got the floor kit from Chassisworks. It needs to be trimmed and fit to the frame and car, and notched for all the roll cage tubing.

dslhtrdr

Always learning...

- Joined

- Sep 2, 2009

- Messages

- 677

yea, thats bad ars!! cant wait to see you running that thing..

Thanks Adam. Hope to racing in May. I'll see you at the track :ft:

j.stanton2009

New member

- Joined

- Sep 11, 2012

- Messages

- 34

Any update?

Im loving this build thread!

Sent from my HTC PH39100 using Tapatalk 2

Im loving this build thread!

Sent from my HTC PH39100 using Tapatalk 2

dslhtrdr

Always learning...

- Joined

- Sep 2, 2009

- Messages

- 677

Any update?

Im loving this build thread!

Sent from my HTC PH39100 using Tapatalk 2

Ask and you shall receive... 3 days later.

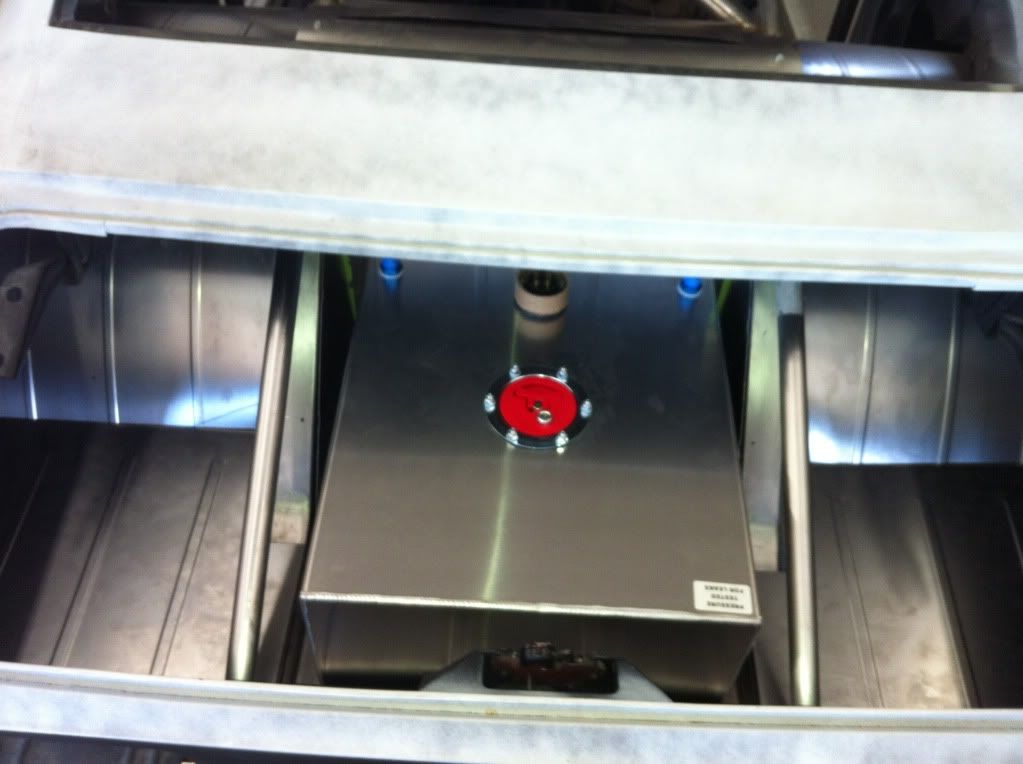

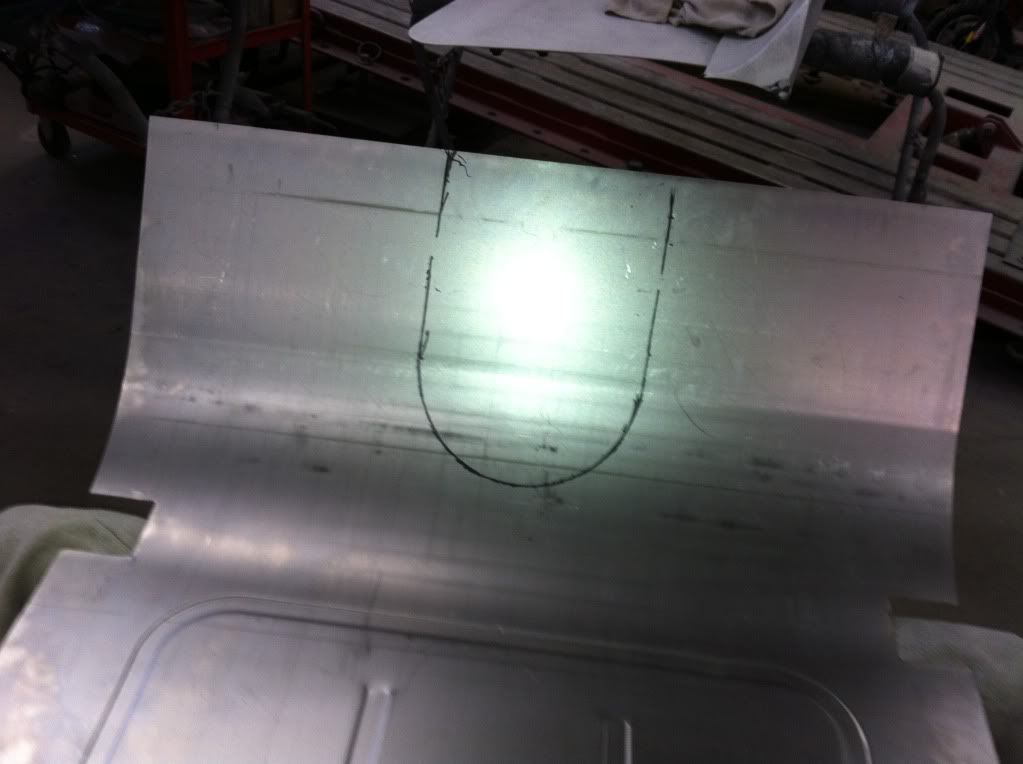

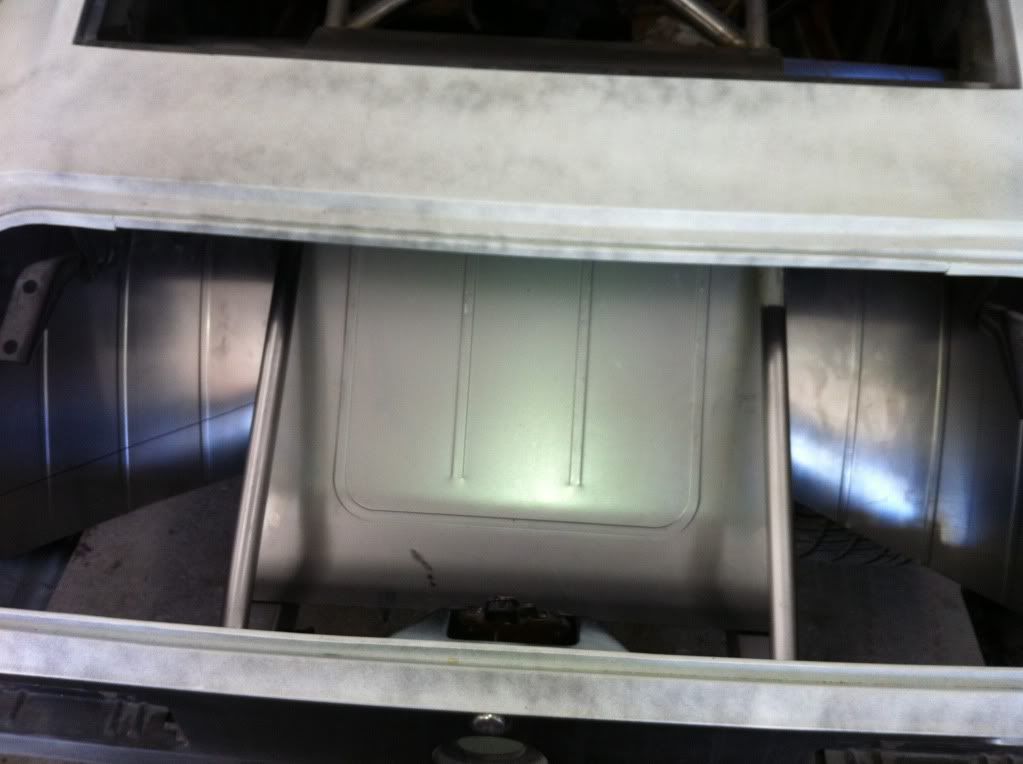

I realized that I didn't take into account that I needed to mount a fuel cell in the trunk, so I had to modify some of my trunk sheet metal.

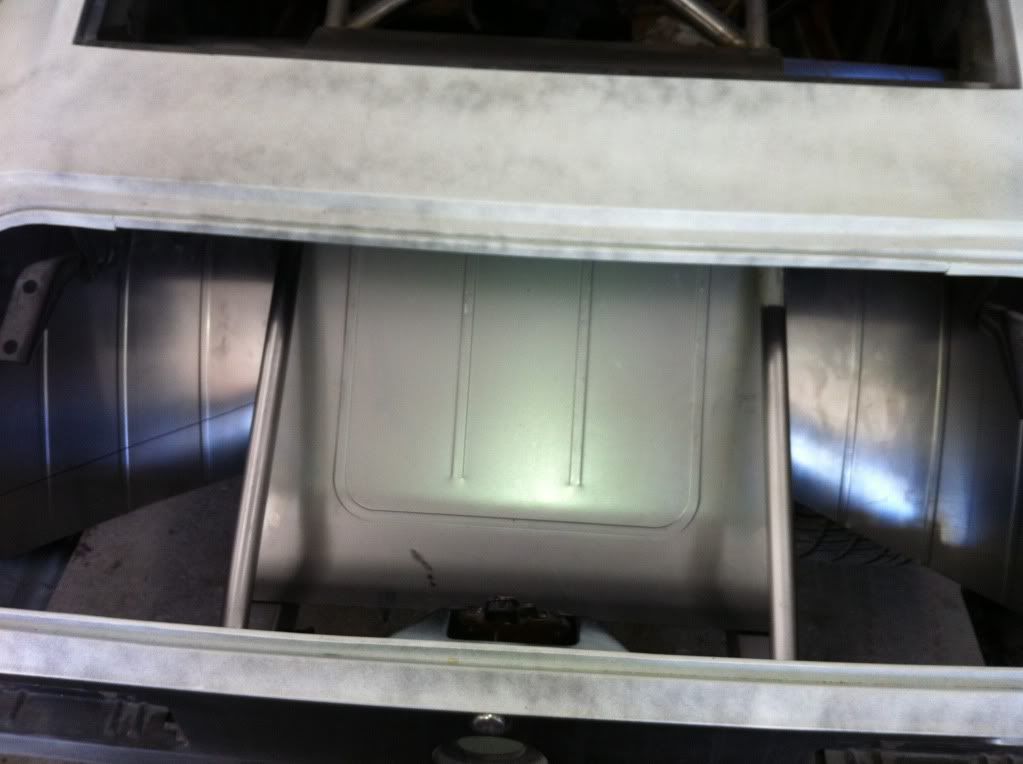

Here's my fuel cell.

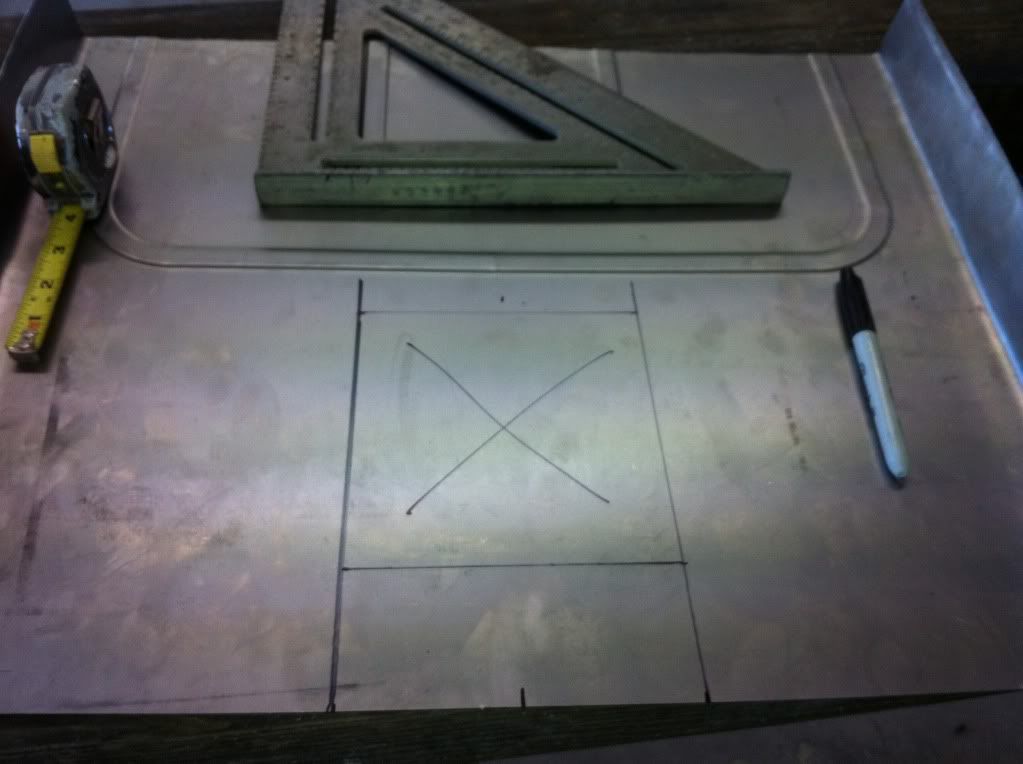

I needed to support the cell, other than sheet metal which wouldn't be strong enough, so I built an x-brace and tied it into the rear subframe.

dslhtrdr

Always learning...

- Joined

- Sep 2, 2009

- Messages

- 677

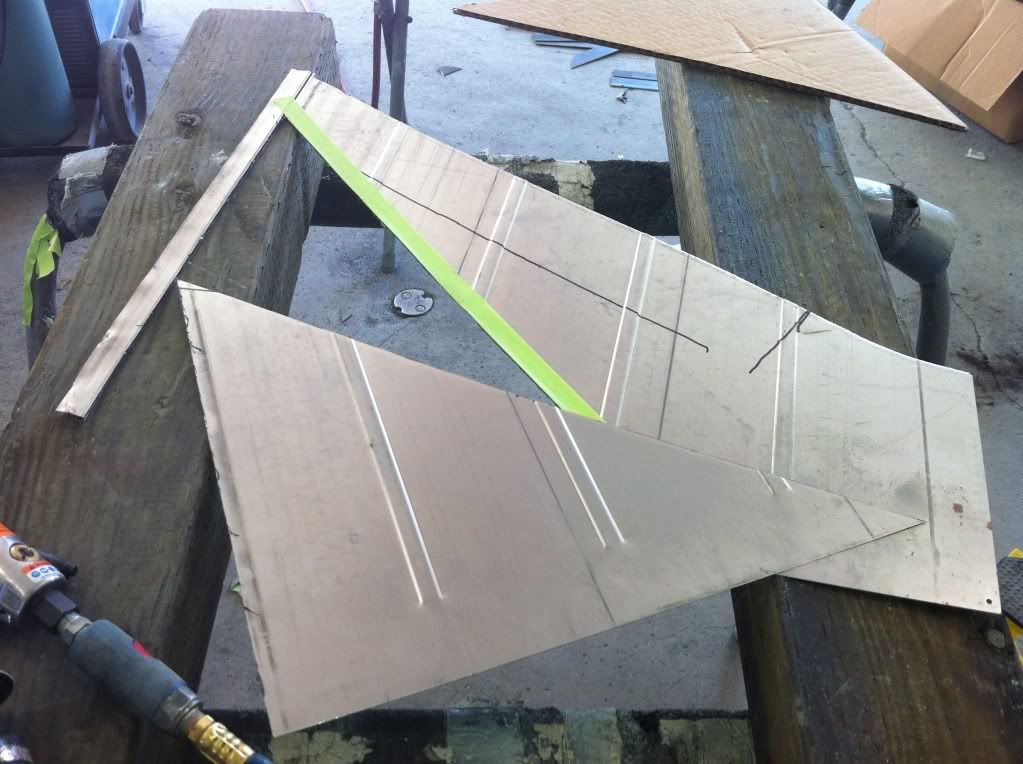

As you can see I had to extensively modify the center trunk floor to allow space for the 15 gallon summit fuel cell. I was able to achieve 3 more inches by lowering the center trunk floor to the x-brace on the bottom of the rear frame rails. Luckily, I was able to reuse the existing floor pieces I had already installed, it just took some thinking and a lot of time. I don't have a sheet metal break, so I had to improvise by using blocks of wood, some straight pieces of flat stock and vise grips to get the bends I needed.

I needed to raise the driveshaft tunnel to go around the driveshaft loop, but didn't want to spend the money on a new tunnel from Chassisworks. I ended up using 2 leftover pieces from the wheel tub extensions that I bent over my leg to get the proper curve to attach to the loop. I made a straight relief cut about 2' long to lift the tunnel up to the extension I made. I think it looks good with the beads rolled in them, kind of like it was meant to be there.

The fuel cell is filled with foam, has a gm sending unit, and has -8 an fittings. I had to remove the fittings in the sump to install the cell in the trunk because it's such a tight fit.

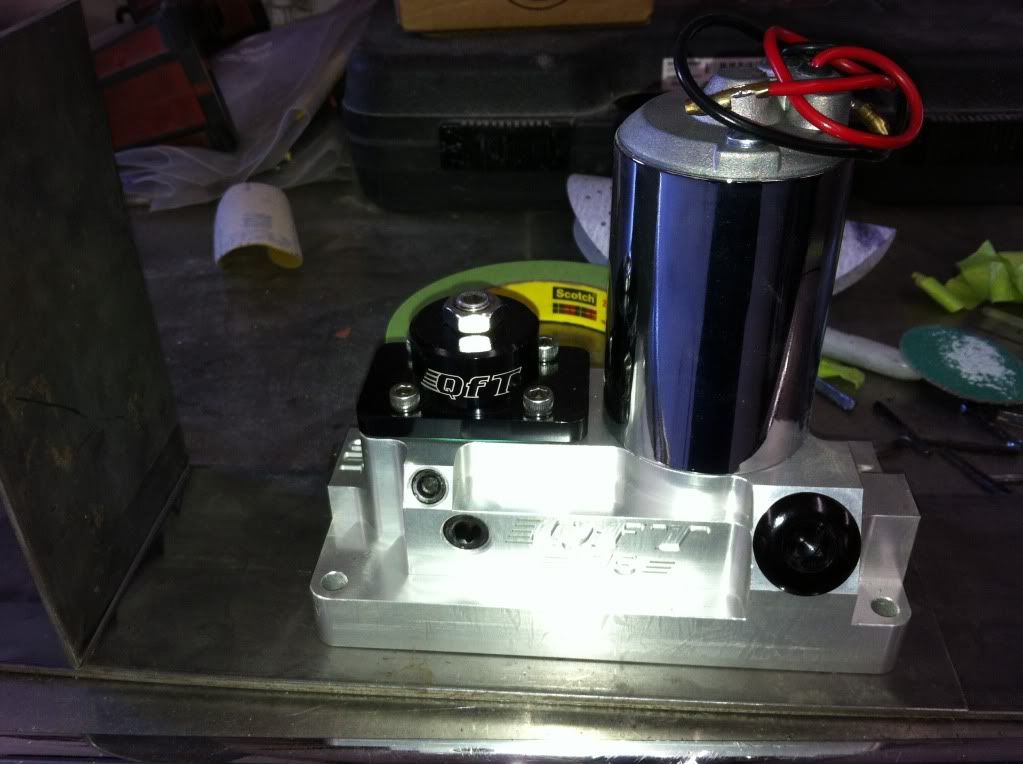

I took JoshH's advise and bought the Quick Fuel 175 gph fuel pump. The bracket it came with wasn't going to work for my application, so I built a bracket/tray for it that also acts as a shield. It sits high enough that it cannot be seen from the back of the car. Still need to finish it.

I needed to raise the driveshaft tunnel to go around the driveshaft loop, but didn't want to spend the money on a new tunnel from Chassisworks. I ended up using 2 leftover pieces from the wheel tub extensions that I bent over my leg to get the proper curve to attach to the loop. I made a straight relief cut about 2' long to lift the tunnel up to the extension I made. I think it looks good with the beads rolled in them, kind of like it was meant to be there.

The fuel cell is filled with foam, has a gm sending unit, and has -8 an fittings. I had to remove the fittings in the sump to install the cell in the trunk because it's such a tight fit.

I took JoshH's advise and bought the Quick Fuel 175 gph fuel pump. The bracket it came with wasn't going to work for my application, so I built a bracket/tray for it that also acts as a shield. It sits high enough that it cannot be seen from the back of the car. Still need to finish it.

j.stanton2009

New member

- Joined

- Sep 11, 2012

- Messages

- 34

Any updates? This is a really badass thread!

Sent from my HTC PH39100 using Tapatalk 2

Sent from my HTC PH39100 using Tapatalk 2

dslhtrdr

Always learning...

- Joined

- Sep 2, 2009

- Messages

- 677

Really enjoy reading about this car. I am envious of your fab skills. Nice work!

Thanks for the compliment.

Any updates? This is a really badass thread!

Sent from my HTC PH39100 using Tapatalk 2

Sadly, no updates to speak of. The last three weekends have been spent making truck repairs. Pulled my girlfriends tranny out to be rebuilt (and built up a bit) only to reinstall it the following weekend and have a massive oil leak from a broken oil pump, so I had to pull it back out, and reinstall it the following weekend. Then to add to that, I blew the head gasket in my 12v, so I took it apart and got a new o ringed head and 625's on it, hoping to finish it before Saturday so I can put some hours in the camaro again.

i think im in love... awsome build

Thanks, I hope I can still get it done by May this year.

YOUNG GUNS15

Im AWESOME!!!!

- Joined

- Sep 24, 2009

- Messages

- 7,346

lookin good! sheetmetal work like that takes some serious skill!