You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

8.3L Cummins Transplant

- Thread starter 4x4dually

- Start date

Snedge

Comp Diesel Sponsor

- Joined

- Sep 1, 2006

- Messages

- 18,923

Oh come on, you guys grew up in the 70's, don't tell me you never played for the other team a few times. LOL

No Mike. No. Even high on cocaine and LSD. :hehe:

- Joined

- Jan 22, 2007

- Messages

- 32,086

FINALLY.....finally got somewhere with finding out where this big bastard was hatched.

It is from a PX240 Power Unit.

http://r.search.yahoo.com/_ylt=AwrBT8iBQbFVzskAtxpXNyoA;_ylu=X3oDMTEyYmF1ZHRuBGNvbG8DYmYxBHBvcwMxBHZ0aWQDQjA0OTJfMQRzZWMDc3I-/RV=2/RE=1437708801/RO=10/RU=http%3a%2f%2frandkpivots.com%2ffiles%2f2013%2f01%2fPX240.pdf/RK=0/RS=BPrRXPuif.nPeMq610YywGTUU6g-

Engine Model/Manufacturer 6TAA-830/CNH Engine Corp.

Engine Type 6 Cyl., 2 valve, turbocharged/charge air cooled

Engine Displacement 8.3 litres (504.5 cu. in.)

Bore and Stroke 114 x 135 mm (4.49 x 5.32 in.)

Compression Ratio 18.0:1

Engine Configuration 6 cylinder, in line, four stroke cycle (firing order 1, 5, 3, 6, 2, 4)

Description Turbocharged, compression ignition, direct injection from

in-line mechanical Robert Bosch injection pump

Governor Breakaway 2275 rpm +/- 25 rpm

Governor Regulation 8% +/- 1 %

High Idle Speed 2460 +/- 60 rpm

Low Idle Speed 1000 rpm +/- 100 rpm

Nominal Power Developed 240 hp (179 kW) @ 2200 rpm

Nominal Max Torque 823 ft-lbs. (1116 Nm) @ 1500 rpm

Altitude Capacity 10,000 ft. (3,050 m)

Engine Certification Tier 2, US EPA heavy-duty non-road emissions Stage IIIA,

EU heavy-duty non-road emissions and

California Air Resources Board (CARB)

823 ft lbs....... :rockwoot: Take that you POS Detroit boat anchor. :hehe:

It is from a PX240 Power Unit.

http://r.search.yahoo.com/_ylt=AwrBT8iBQbFVzskAtxpXNyoA;_ylu=X3oDMTEyYmF1ZHRuBGNvbG8DYmYxBHBvcwMxBHZ0aWQDQjA0OTJfMQRzZWMDc3I-/RV=2/RE=1437708801/RO=10/RU=http%3a%2f%2frandkpivots.com%2ffiles%2f2013%2f01%2fPX240.pdf/RK=0/RS=BPrRXPuif.nPeMq610YywGTUU6g-

Engine Model/Manufacturer 6TAA-830/CNH Engine Corp.

Engine Type 6 Cyl., 2 valve, turbocharged/charge air cooled

Engine Displacement 8.3 litres (504.5 cu. in.)

Bore and Stroke 114 x 135 mm (4.49 x 5.32 in.)

Compression Ratio 18.0:1

Engine Configuration 6 cylinder, in line, four stroke cycle (firing order 1, 5, 3, 6, 2, 4)

Description Turbocharged, compression ignition, direct injection from

in-line mechanical Robert Bosch injection pump

Governor Breakaway 2275 rpm +/- 25 rpm

Governor Regulation 8% +/- 1 %

High Idle Speed 2460 +/- 60 rpm

Low Idle Speed 1000 rpm +/- 100 rpm

Nominal Power Developed 240 hp (179 kW) @ 2200 rpm

Nominal Max Torque 823 ft-lbs. (1116 Nm) @ 1500 rpm

Altitude Capacity 10,000 ft. (3,050 m)

Engine Certification Tier 2, US EPA heavy-duty non-road emissions Stage IIIA,

EU heavy-duty non-road emissions and

California Air Resources Board (CARB)

823 ft lbs....... :rockwoot: Take that you POS Detroit boat anchor. :hehe:

- Joined

- Jan 22, 2007

- Messages

- 32,086

And all the parts and filters. Whew. Glad to figure out something.

http://www.messicks.com/cas/50431

http://www.messicks.com/cas/50431

madmikeismad

So mad

- Joined

- Dec 19, 2009

- Messages

- 14,347

dat torque doh

- Joined

- Jan 22, 2007

- Messages

- 32,086

dat torque doh

I have no idea what these engines are capable of with slight IP tweaks....but it looks promising.

TheBigNasty

Project bish

- Joined

- May 9, 2007

- Messages

- 5,385

No Mike. No. Even high on cocaine and LSD. :hehe:

That wasn't a lollipop.

Snedge

Comp Diesel Sponsor

- Joined

- Sep 1, 2006

- Messages

- 18,923

That wasn't a lollipop.

Not gay. bif

madmikeismad

So mad

- Joined

- Dec 19, 2009

- Messages

- 14,347

What was stock tq for that Detroit?

- Joined

- Jan 22, 2007

- Messages

- 32,086

What was stock tq for that Detroit?

4.25

- Joined

- Jan 22, 2007

- Messages

- 32,086

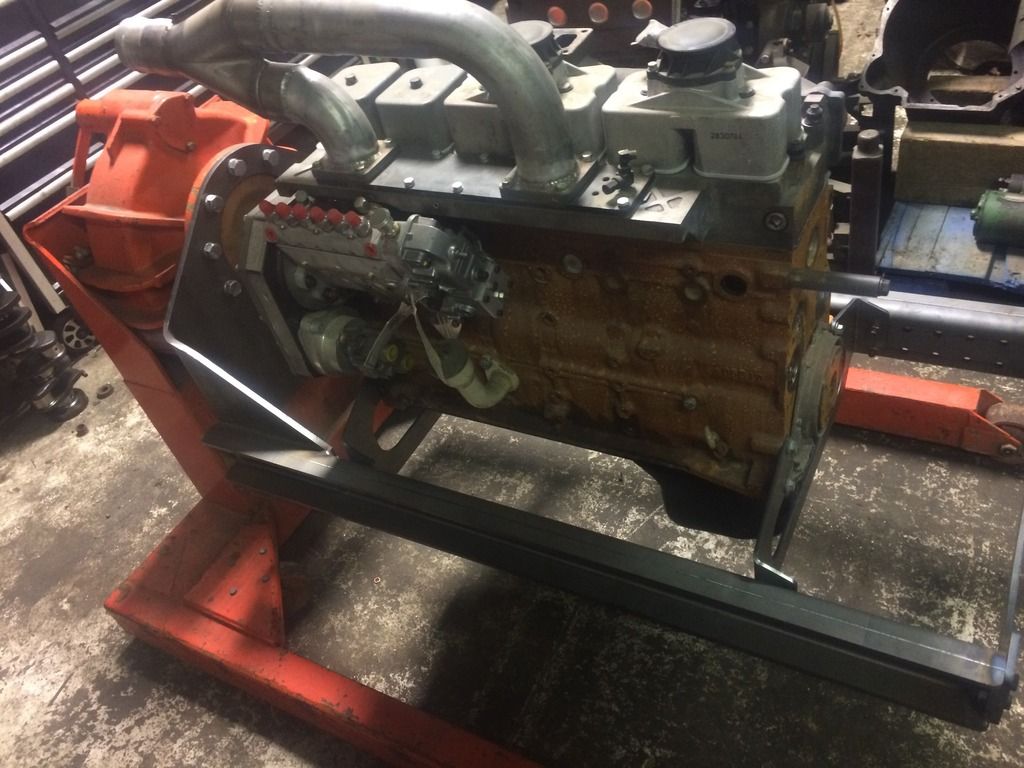

Engine stand located. Picking up tomorrow morning from a buddy. For some reason I guess I thought these motors mounted to a stand on the side of the block. It will never rotate if that is the deal. I guess I make a plate to mount it to the bell housing? Will it hold up that long SOB like that?

Attachments

- Joined

- Jan 22, 2007

- Messages

- 32,086

Thanks for the info. I'll try to get it up on the rack tomorrow and start removing things I don't need....like the injection pump. :evil

I now have part number for all the filters, oil, fuel, water, water separator, etc. I can give you those numbers if you think you will have them and you can ship them to me. Or if you don't think it would be worth your time, I can try to find them local and save the shipping. Up to you. I'll give you the binnes if you want it.

I now have part number for all the filters, oil, fuel, water, water separator, etc. I can give you those numbers if you think you will have them and you can ship them to me. Or if you don't think it would be worth your time, I can try to find them local and save the shipping. Up to you. I'll give you the binnes if you want it.

TheBigNasty

Project bish

- Joined

- May 9, 2007

- Messages

- 5,385

I believe most hang them from the side because their stands won't hold it the other way. Grown ass man stands can handle it from the rear. No homo.

zfaylor

Comp Diesel Sponsor

- Joined

- Nov 21, 2010

- Messages

- 5,024

We have dis

https://www.otctools.com/products/6000-lb-revolver-diesel-engine-stand

It mounts from the side but all of the adapters push the engine out pretty far. I wouldn't see much of an issue mounting a lil 8.3 from the end.

https://www.otctools.com/products/6000-lb-revolver-diesel-engine-stand

It mounts from the side but all of the adapters push the engine out pretty far. I wouldn't see much of an issue mounting a lil 8.3 from the end.

Snedge

Comp Diesel Sponsor

- Joined

- Sep 1, 2006

- Messages

- 18,923

I now have part number for all the filters, oil, fuel, water, water separator, etc. I can give you those numbers if you think you will have them and you can ship them to me. Or if you don't think it would be worth your time, I can try to find them local and save the shipping. Up to you. I'll give you the binnes if you want it.

Shoot me the list in my email. You should maybe get it in there and running before we sell you too many filters.

- Joined

- Jan 22, 2007

- Messages

- 32,086

Holy crap, Brad! You are dying to make me get out Solidworks and design a cradle. What the hell? LOL

I was going to ask this morning.....therefor I will now....will the cast flywheel housing I have hold it if I simply cut the SAE 3 bolt pattern on the outside of a piece of 3/4" plate and the hub pattern on the stand in the center or is that too much counter-levered weight on the flywheel housing?

It's easier to measure and cut round patterns than to try to match that dang block....but I don't want it to fall. What say all?

I was thinking I could make a bracket that bolts on the front where the fan bracket is missing and it could take some of the weight off the back.

I was going to ask this morning.....therefor I will now....will the cast flywheel housing I have hold it if I simply cut the SAE 3 bolt pattern on the outside of a piece of 3/4" plate and the hub pattern on the stand in the center or is that too much counter-levered weight on the flywheel housing?

It's easier to measure and cut round patterns than to try to match that dang block....but I don't want it to fall. What say all?

I was thinking I could make a bracket that bolts on the front where the fan bracket is missing and it could take some of the weight off the back.

Last edited:

Signature600

THA MAN!

- Joined

- Aug 5, 2006

- Messages

- 12,015

I really don't see a problem using the flywheel housing. Only reason you don't see that done is you can't tear it apart like that. Can't get the crank out.

For what you're doing, you don't care.

Chris

For what you're doing, you don't care.

Chris