You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ahale's 94 Build thread

- Thread starter ahale2772

- Start date

ahale2772

New member

- Joined

- Oct 27, 2011

- Messages

- 2,442

looks like I need a new Pump, 160 pump has a serious sticking rack/plunger that is becoming rather dangerous.

I'm going to look for a 180/215, not sure If I want to save and spend the dough to send the pump out to get benched, if not, it will just get my 5k's, dv's, rack plug, and afc swapped... I know that will be more than enough fuel for my goals, just not sure if i want to shell out the cash to get the pump balanced at the same time.

I'm going to look for a 180/215, not sure If I want to save and spend the dough to send the pump out to get benched, if not, it will just get my 5k's, dv's, rack plug, and afc swapped... I know that will be more than enough fuel for my goals, just not sure if i want to shell out the cash to get the pump balanced at the same time.

ahale2772

New member

- Joined

- Oct 27, 2011

- Messages

- 2,442

on another note, ive been busy the last few days, built a compound setup for a local truck... kind of a weird setup, it was fun to build.

366 over 475... yes, not ideal, but the typical "i got the turbo for a song deal" I'm trying to get him to trade the 66 wheel for a 62... or trade the whole fatshaft all together.

anyways, pictures, because everyone loves pictures.

366 over 475... yes, not ideal, but the typical "i got the turbo for a song deal" I'm trying to get him to trade the 66 wheel for a 62... or trade the whole fatshaft all together.

anyways, pictures, because everyone loves pictures.

ahale2772

New member

- Joined

- Oct 27, 2011

- Messages

- 2,442

Ive got a 887 215 pump coming to replace the 160, excited about that. I may dabble with trying to take a spare pump apart to swap out the 215's notched plungers.

really need to get a nice lift pump in this thing.

Local Dyno day is on the 30th, I wonder what it will put down. hoping closer to 700 if I manage to get a lift pump on it.

as always.....if the transmission holds

really need to get a nice lift pump in this thing.

Local Dyno day is on the 30th, I wonder what it will put down. hoping closer to 700 if I manage to get a lift pump on it.

as always.....if the transmission holds

displacedtexan

$500 PREMIUM MEMBER

- Joined

- Feb 6, 2008

- Messages

- 13,888

displacedtexan likes this!

ahale2772

New member

- Joined

- Oct 27, 2011

- Messages

- 2,442

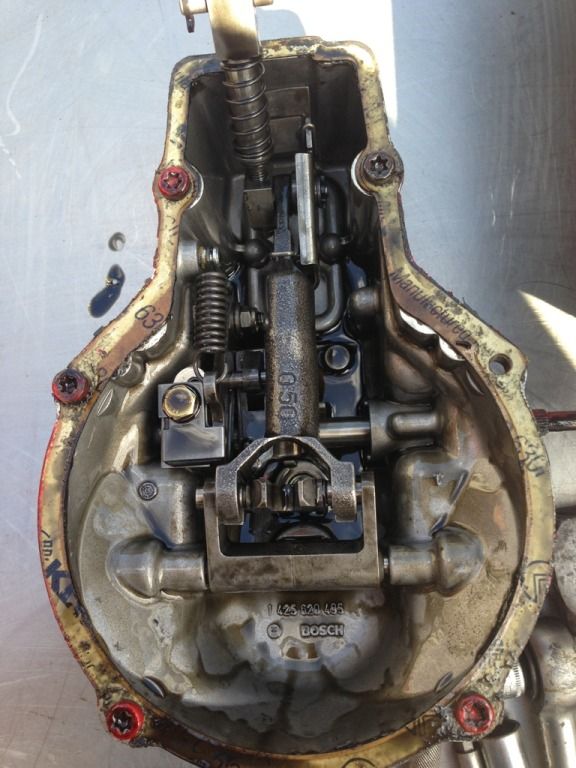

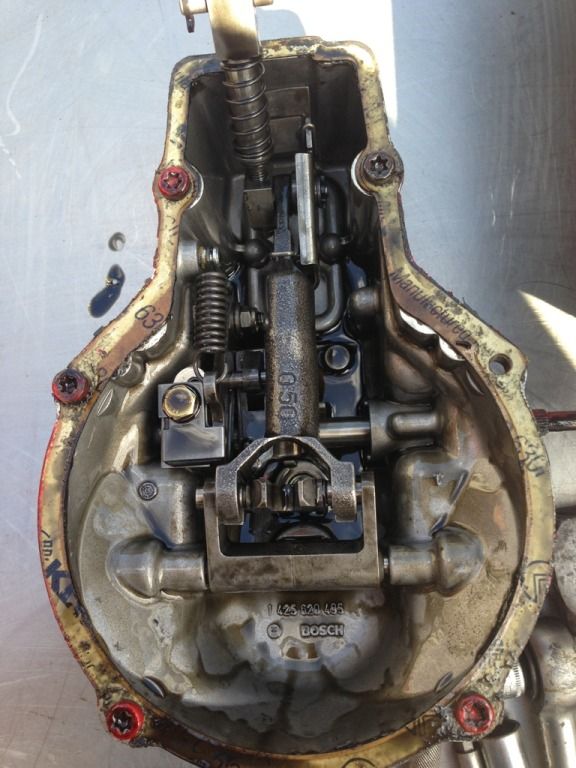

some photos of the day's acomplishments.

gov with the gov arm off.

decided to pull the cam out with the gov still on it, no real need to pull the assembly apart for what I was doing.

all apart.

crappy pic of the roller tappets in, compressed, with the tools to hold them in place. the tools from rocken tech were borderline useless.

all done...

tomorrow morning I'm off to have it benched, before that I need to swap out a set of 191DV's and throw them in the pump, id like to start with them, and go from there.

gov with the gov arm off.

decided to pull the cam out with the gov still on it, no real need to pull the assembly apart for what I was doing.

all apart.

crappy pic of the roller tappets in, compressed, with the tools to hold them in place. the tools from rocken tech were borderline useless.

all done...

tomorrow morning I'm off to have it benched, before that I need to swap out a set of 191DV's and throw them in the pump, id like to start with them, and go from there.

displacedtexan

$500 PREMIUM MEMBER

- Joined

- Feb 6, 2008

- Messages

- 13,888

Congrats man!

YOUNG GUNS15

Im AWESOME!!!!

- Joined

- Sep 24, 2009

- Messages

- 7,346

This is what I like to see! Good on ya for tackling the pump!

ahale2772

New member

- Joined

- Oct 27, 2011

- Messages

- 2,442

Thanks!

Only tools i bought were from rokentech, the tappet lifter tools, they were crappy quality and i screwed up a few of the roller lifter bores because of how the tool does not seat in the plug bore. There is barely a 1/16 of an inch of in an out where you will either not be able to turn the cam, or the eccentric on the end of the tool will hang on the aluminum at the end lf the bore. A little 80 grit took the burs off and its all fine.

Otherwise, just needed a press to compress the lifters, and an extra set of hands thanks to my buddy chris, aka 1stgenCTD

Pump is at a local shop getting benched hopefully today.

Sal at Boston injection was surprised when i told him it just wanted to be balanced, and that it was going to flow some serious fuel. He was going to set it to stock. I told him good luck with 5k springs, rack plug, 191's no plate and 13mm p&b's. LOL

Hopefully i get it back before the weekend.

Only tools i bought were from rokentech, the tappet lifter tools, they were crappy quality and i screwed up a few of the roller lifter bores because of how the tool does not seat in the plug bore. There is barely a 1/16 of an inch of in an out where you will either not be able to turn the cam, or the eccentric on the end of the tool will hang on the aluminum at the end lf the bore. A little 80 grit took the burs off and its all fine.

Otherwise, just needed a press to compress the lifters, and an extra set of hands thanks to my buddy chris, aka 1stgenCTD

Pump is at a local shop getting benched hopefully today.

Sal at Boston injection was surprised when i told him it just wanted to be balanced, and that it was going to flow some serious fuel. He was going to set it to stock. I told him good luck with 5k springs, rack plug, 191's no plate and 13mm p&b's. LOL

Hopefully i get it back before the weekend.

Last edited:

TMONEYDIESEL

Comp Diesel Sponsor

- Joined

- Jan 21, 2007

- Messages

- 8,706

Was this taken apart & assembled outside?