You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

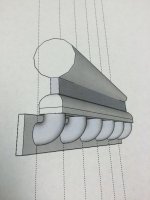

Anybody else make an intake runner plate?

- Thread starter m880cummins

- Start date

Str8jacket

New member

- Joined

- Aug 24, 2013

- Messages

- 66

I think it is recommended to have a larger main plenum body, the small cone plenum increases velocity through the slot joining the main plenum and the large increase in size quickly reduces the velocity of the air and increase in pressure is supposed to disperse it more evenly. Plenum size is usually the total engine displacement or larger. That is my understanding of how it is supposed to work.

But the drawing is pretty much on the money.

But the drawing is pretty much on the money.

Ghostman

24v crazy

- Joined

- Aug 24, 2012

- Messages

- 2,819

So the basic principal between that type of Intake is to distribute air equally across all cylinders correct? Looks like it would be easy to build if bolted to a stock type shelf

Yes, except the stock shelf flange is short so would it still work? As in it doesn't extend to the back and 5,6 and front 1 cylinders.

I think it is recommended to have a larger main plenum body, the small cone plenum increases velocity through the slot joining the main plenum and the large increase in size quickly reduces the velocity of the air and increase in pressure is supposed to disperse it more evenly. Plenum size is usually the total engine displacement or larger. That is my understanding of how it is supposed to work.

But the drawing is pretty much on the money.

So like a 4" diameter main plenum 36" long is 452cuin so thats a bit larger than engine displacement so that would work? How do you size the cone though and the slot?

Ghostman

24v crazy

- Joined

- Aug 24, 2012

- Messages

- 2,819

maybe anecdotal... but for industrial air handling I've read that the calculated flow velocity of the plenum must be at a maximum of 1/2 the value of the flow velocity through the branches/slots/ect for equal distribution.

So using generic numbers, your saying, if the slot(between cone and main plenum) flows 100, then the plenum must flow max of 50? But how do you come up with those calculations on a head?

m880cummins

New member

- Joined

- Apr 29, 2013

- Messages

- 142

Here is a cone style one we built. Sounds like you are thinking of doing something similar.

That's almost exactly what I am thinking about doing. The only difference is I want to tilt the elbows 15-20* towards the air source.

The Lehmann is a really neat concept but we need to do some more calculations to see how big it needs to be.

Thanks for all of the info guys!

Charlie

m880cummins

New member

- Joined

- Apr 29, 2013

- Messages

- 142

Looking at using a stainless cone from http://www.coneeng.com part number CN20SS-204028.

The cone's dimensions are 4" inlet, 2" outlet, 28" long. I calculated the volume of the cone to be 205.15 cubic inches. I wonder if it would matter the CIS (cubic inches per second) of the turbo in regards to sizing the runner. Too large of a runner may mean a delay in turbo response? Looks like I will be looking up some flow charts of S362s.....

The cone's dimensions are 4" inlet, 2" outlet, 28" long. I calculated the volume of the cone to be 205.15 cubic inches. I wonder if it would matter the CIS (cubic inches per second) of the turbo in regards to sizing the runner. Too large of a runner may mean a delay in turbo response? Looks like I will be looking up some flow charts of S362s.....

Ghostman

24v crazy

- Joined

- Aug 24, 2012

- Messages

- 2,819

So if a person where to get a blank intake plate cut for a head with shelf still attached, and fab up a rectangular slot the length of the plate and a couple inches tall, with a cone on top of that(4" x 2"), would it actually be any better than the regular horn/s?

m880cummins

New member

- Joined

- Apr 29, 2013

- Messages

- 142

Well, only the dyno sheets would tell so maybe its time we start making some parts. With what you suggested, it would be a top priority to find some aftercooled P7100 lines off a bus.

I personally think in concept, it would help but what is on paper doesn't always translate to real world. I was never a fan of the air coming in the center and hitting the head plenum head on so maybe a way to distribute the air like the Lehmann would help

I personally think in concept, it would help but what is on paper doesn't always translate to real world. I was never a fan of the air coming in the center and hitting the head plenum head on so maybe a way to distribute the air like the Lehmann would help

97rada

New member

- Joined

- Feb 14, 2008

- Messages

- 5,410

So if a person where to get a blank intake plate cut for a head with shelf still attached, and fab up a rectangular slot the length of the plate and a couple inches tall, with a cone on top of that(4" x 2"), would it actually be any better than the regular horn/s?

I would try it on the dyno if you made it haha.

I don't see how it wouldn't be an improvement, its still allows air to have "better " distribution that the stock elbo allows.

RascalMafia

heyyyyyyy girrrrrrrl

- Joined

- Apr 4, 2007

- Messages

- 5,514

That's an SMT intake.If I remember what I saw under Brandon overmeyers hood, seems to fit what a few are trying to describe??

RascalMafia

heyyyyyyy girrrrrrrl

- Joined

- Apr 4, 2007

- Messages

- 5,514

cumminspa75

New member

- Joined

- Mar 22, 2010

- Messages

- 301

I can't remember which thread it was on here but it discussed the volume used in a typical runner intake. I remember reading that the "ideal" volume was 150% of the engines displacement.

m880cummins

New member

- Joined

- Apr 29, 2013

- Messages

- 142

I like where this is going.... My issue is I can't fit 150% the volume of the engine's displacement under my hood.... The front valve cover is only a couple inches shy of hitting the hood... I'm assuming the volume would include the individual elbows?

Charlie

Charlie

cumminspa75

New member

- Joined

- Mar 22, 2010

- Messages

- 301

I like where this is going.... My issue is I can't fit 150% the volume of the engine's displacement under my hood.... The front valve cover is only a couple inches shy of hitting the hood... I'm assuming the volume would include the individual elbows?

Charlie

Theres no reason to assume otherwise with my logic. One day ill know more about compressible fluid dynamics. Until them I'll continue making SWAG'S ( Scientific Wild Ass Guesses)

kjpcummins

New member

- Joined

- Feb 15, 2009

- Messages

- 2,322

At 4-5000rpm you want the plenum in the 1.1-1.2 x ci. If you turning say 8000rpm you want more in the 1.8-2 x ci range. The opening between the main plenum and cone section is dependent on your pipe size. Runner length and size is dependent on rpm and ci. Most of the gains are under the curve but you can pick up some peak hp.

Penni

New member

- Joined

- Oct 5, 2010

- Messages

- 1,351

Do we have any closer pictures of this?