You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

G.M. Performance Parts Duramax Diesel Top Dragster final prep for testing .

- Thread starter COMP461

- Start date

JasonCzerak

Active member

- Joined

- Aug 10, 2006

- Messages

- 14,826

I'll stick with Isspro. Cause they stick with us diesel guys.

Bump on that! I'm not buying another autometer... Next up, ISSPRO data logging setup.

Torque Monkey

The show stopper!!!!!

- Joined

- Jul 15, 2008

- Messages

- 466

Bump on that! I'm not buying another autometer... Next up, ISSPRO data logging setup.

I have it and it works great!

JasonCzerak

Active member

- Joined

- Aug 10, 2006

- Messages

- 14,826

I have it and it works great!

Looks kinda cool to have 8 gauges + the OEM stuff, but that's about it. ;-) Now with these twins I need another boost gauge! For the short term I'm going to use my drive pressure gauge to get the them dialed in and just flip between the two manually.

Next winter I"ll re-wire all that crap slowly in a heated garage!

inline6power

more hp than you

- Joined

- Apr 15, 2007

- Messages

- 3,485

Greg if you ever need more room for your leg from that side lockout shifter, check out precision performance shifters. Super nice piece and way slimmer than yours with the lockout and or transbrake implemented into the handle

inline6power

more hp than you

- Joined

- Apr 15, 2007

- Messages

- 3,485

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

Thanks The picture is making it look like it’s over farther then it really is. The shifter is a Frame works. Plus I’m a little sentimental about that shifter, it’s been in both of my comp cars and now it’s in the dragster. I’ve seen the shifter you’re talking about and had one in the SS/DM when I went with the Scott McClay THM200 3 speed transmission looking for a few hundreds

inline6power

more hp than you

- Joined

- Apr 15, 2007

- Messages

- 3,485

Thanks The picture is making it look like it’s over farther then it really is. The shifter is a Frame works. Plus I’m a little sentimental about that shifter, it’s been in both of my comp cars and now it’s in the dragster. I’ve seen the shifter you’re talking about and had one in the SS/DM when I went with the Scott McClay THM200 3 speed transmission looking for a few hundreds

Sounds good. Keep us posted

sent from my galaxy s3

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

working on Drive pressure sensors for the RPM data logger. The cool thing about the RPM computer is you can use any 0 to 5 volt dc sensor. with out using a 18 inch peice of copper tubing , what about the sensor on a power stroke or 6.7

THATpreston

Brush your teeth.

- Joined

- Apr 30, 2006

- Messages

- 5,179

I got all of the AutoMeter carbon fiber gauges in and installed. AutoMeter is always the finishing touch to any race car.

I can only look at this thread so often....it just turns into an infomercial. I keep waiting for you to tell us you wipe it down with a Shamwow. Sorry Greg...it's how it comes across. Get it done and go make a pass. That's what we want to see.

Last edited:

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

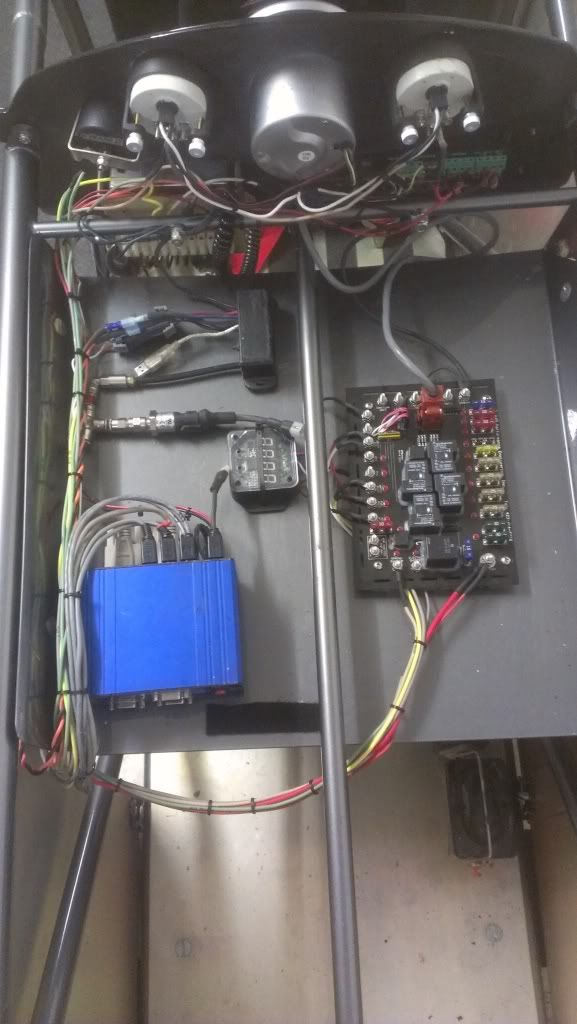

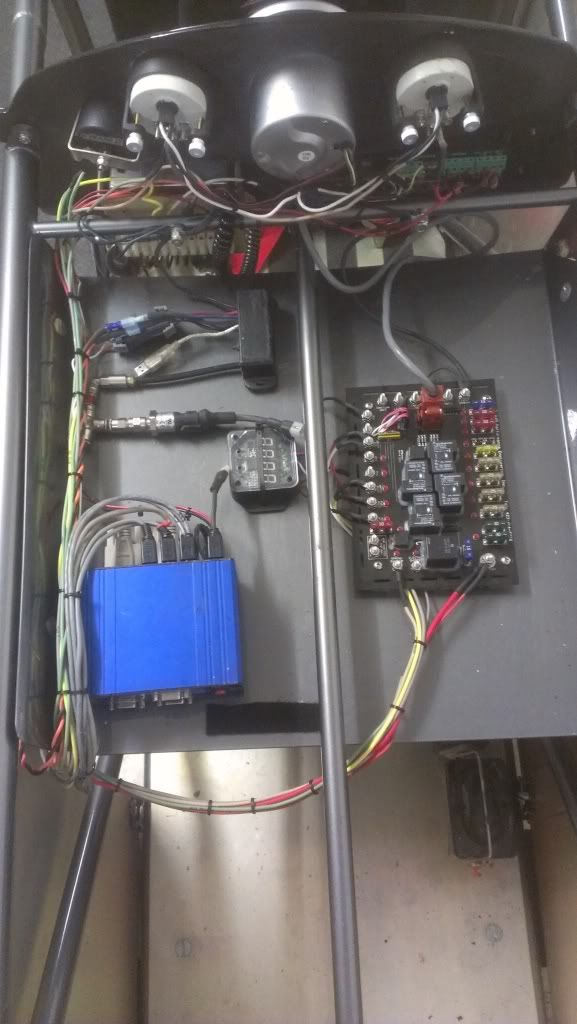

The wiring is done; The RPM Performance Data logger is ready to catch up to 28 channels of critical data. The K&R Pro Cube is ready to time the functions including the 4 four timers, delay box and throttle stop for 8.90 super comp racing. I have spent over 100 hours in this wiring job alone

Michael

Comp Diesel Sponsor

- Joined

- Apr 25, 2006

- Messages

- 3,411

Those sensors are still mounted at the end of a tube to keep the temperature reasonable, no currently available capacitive pressure sensors will live at the exhaust gas temperatures. Just coil up 24" or so of 3/16" copper tubing (with the axis of the coil vertically oriented, so it is always "uphill" from the exhaust to the sensor).working on Drive pressure sensors for the RPM data logger. The cool thing about the RPM computer is you can use any 0 to 5 volt dc sensor. with out using a 18 inch peice of copper tubing , what about the sensor on a power stroke or 6.7