I will re-emphasize several points regarding Dynojets that have been mentioned many times in the past.

1- There really is no "calibrating" that is needed on a Dynojet. If all the sensors are clean, it works. If not, it doesn't work. And when I say "doesn't work" does not mean it reads low, it means it doesn't work!!

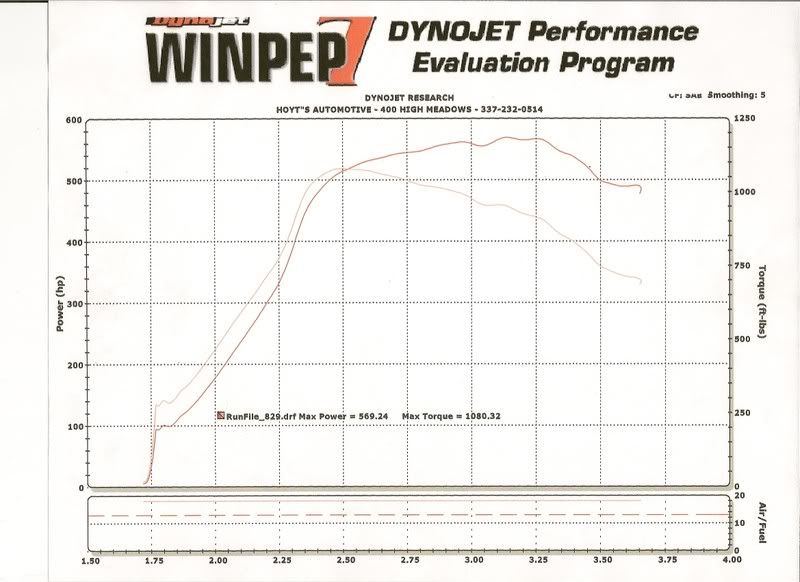

2- A Dynojet is an accelerometer. It measures the HP, or work, it takes to accelerate a known weight (the drum), over a given time. You can't "fool" it.

3- If your uncorrected HP obtained on a Dynojet is not within 5% of your trap speed calculated HP, it merely

shows your setup is not tuned properly!! It does NOT mean it's reading low!!

4- Doing 3 pulls on a dyno a couple times a year will only produce a number!! It takes hours and many pulls on the dyno to "tune" the truck and get "real" "track driven" HP numbers!

oke: