NMB2

Banned

- Joined

- Mar 1, 2012

- Messages

- 469

Ok, now that I have gathered a bit more information on my setup/conditions and have a decent amount of miles on this engine (5,000) I feel its time to tie up the "loose ends". I have currently been focused on body work/interior and the truck isn't in my possession for the next 2 weeks so I figure this is a good time to figure some engine technical things out.

Engine:

6.9 International IDI diesel (7liter actual displacement)

Custom turbo setup, cam, fuel system... everything. I have taken this engine into a completely gray area, there is no other engine to compare my results issues to.

I thought when building it I had a good enough idea on turbo maps, and some of the diesel sites I posted on said everything looked good, but I'm almost convinced at this point my turbocharger is too small. I wanted to wait to get back pressure readings and as much info as I could before presenting it here.

the turbocharger is a BWS300 - 62/74/14 T-3 twin scroll. Stock cast 7blade ETT and "tractor" cover.

My "issue" is that it will not clean up smoke under WOT. WOT on fuel only I see 30psi boost, and it smokes like a freight train. If I meter it with the right foot, 25psi is the "breaking point" @ 25psi I have no smoke.... 25psi is roughly just over 1/2 throttle. Mash it and it jumps up to 30 and smokes like a freight train. User water/methanol injection I can get 35psi with a 40% mix.

At 30psi boost, I have about 37-38psi back pressure, @ 35psi boost the back pressure spikes up, but I never hold into it long enough to see it go over 45psi, although it jumps up quick enough that it gets there fast.

As for fuel levels.... I have a 150cc injection pump. Only other comparison I have is a buddies built up IDI which is 7.3 liter, he has same injectors, and same turbo with a 90cc injection pump. He see's 20psi boost and its completely clean. His engine is 21.1:1 CR, mine is roughly 18.5:1

Here is a video to show the amount of smoke I see under WOT, 30-35psi:

20psi boosted launch

[ame="http://www.youtube.com/watch?v=kA9bTciAt_M&hd=1"]http://www.youtube.com/watch?v=kA9bTciAt_M&hd=1[/ame]

I used these two links to try and "map" my compressor a few months back when choosing turbos:

Compressor map reading for dummies. - HondaSwap Forums

Compressor Flow Map Calculator

Using those two links I came up with these:

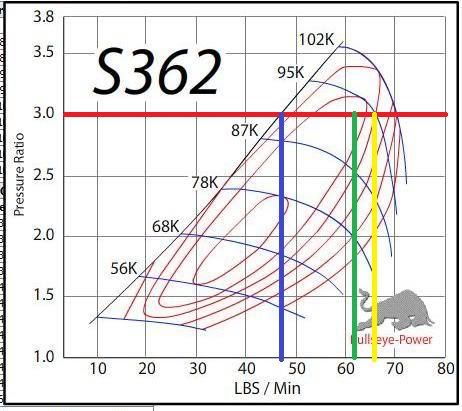

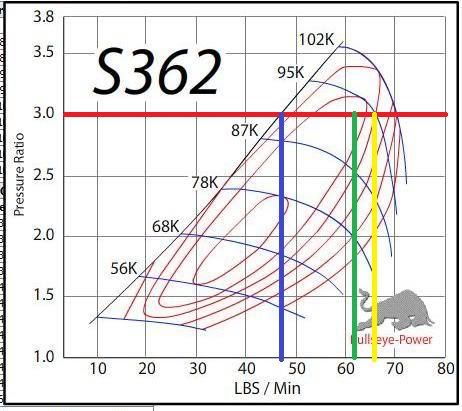

This map is for 30psi... green line is 3000rpm, yellow is 3200rpm.

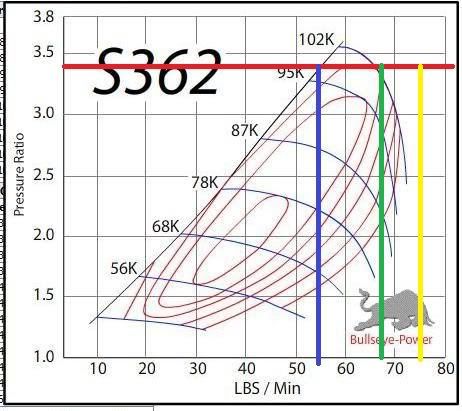

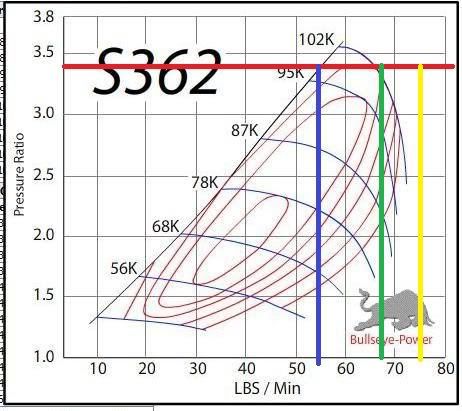

This map is 35psi, colors are the same.

I was put under the understanding that the 30psi map was perfect, and the 35 was "OK". Did I do something wrong? Have I been taught wrong? It would seem to me that my compressor is much too small for what I'm doing. I am considering upgrading to the Bullseye Billet 6blade race wheel, but am worried that that $450 will be wasted if its still not large enough.

one other thing that just crossed my mind.

When I used that spreadsheet to map out the compressor map, I entered 80% VE, as that is what is the accepted VE of one of these engines. I have thought about it before, that boost increases your VE, but never really messed with the calc. I just changed VE from 80% to 95% and 100% to see the differences @ 30psi and its pretty dramatic, and throws me way off the map past 25psi. Is this the problem with my maps?

I posted this up on theturboforums, but I wanted to hear from turbo educated diesel guys as well.

Thanks in advance for the help.

Engine:

6.9 International IDI diesel (7liter actual displacement)

Custom turbo setup, cam, fuel system... everything. I have taken this engine into a completely gray area, there is no other engine to compare my results issues to.

I thought when building it I had a good enough idea on turbo maps, and some of the diesel sites I posted on said everything looked good, but I'm almost convinced at this point my turbocharger is too small. I wanted to wait to get back pressure readings and as much info as I could before presenting it here.

the turbocharger is a BWS300 - 62/74/14 T-3 twin scroll. Stock cast 7blade ETT and "tractor" cover.

My "issue" is that it will not clean up smoke under WOT. WOT on fuel only I see 30psi boost, and it smokes like a freight train. If I meter it with the right foot, 25psi is the "breaking point" @ 25psi I have no smoke.... 25psi is roughly just over 1/2 throttle. Mash it and it jumps up to 30 and smokes like a freight train. User water/methanol injection I can get 35psi with a 40% mix.

At 30psi boost, I have about 37-38psi back pressure, @ 35psi boost the back pressure spikes up, but I never hold into it long enough to see it go over 45psi, although it jumps up quick enough that it gets there fast.

As for fuel levels.... I have a 150cc injection pump. Only other comparison I have is a buddies built up IDI which is 7.3 liter, he has same injectors, and same turbo with a 90cc injection pump. He see's 20psi boost and its completely clean. His engine is 21.1:1 CR, mine is roughly 18.5:1

Here is a video to show the amount of smoke I see under WOT, 30-35psi:

20psi boosted launch

[ame="http://www.youtube.com/watch?v=kA9bTciAt_M&hd=1"]http://www.youtube.com/watch?v=kA9bTciAt_M&hd=1[/ame]

I used these two links to try and "map" my compressor a few months back when choosing turbos:

Compressor map reading for dummies. - HondaSwap Forums

Compressor Flow Map Calculator

Using those two links I came up with these:

This map is for 30psi... green line is 3000rpm, yellow is 3200rpm.

This map is 35psi, colors are the same.

I was put under the understanding that the 30psi map was perfect, and the 35 was "OK". Did I do something wrong? Have I been taught wrong? It would seem to me that my compressor is much too small for what I'm doing. I am considering upgrading to the Bullseye Billet 6blade race wheel, but am worried that that $450 will be wasted if its still not large enough.

one other thing that just crossed my mind.

When I used that spreadsheet to map out the compressor map, I entered 80% VE, as that is what is the accepted VE of one of these engines. I have thought about it before, that boost increases your VE, but never really messed with the calc. I just changed VE from 80% to 95% and 100% to see the differences @ 30psi and its pretty dramatic, and throws me way off the map past 25psi. Is this the problem with my maps?

I posted this up on theturboforums, but I wanted to hear from turbo educated diesel guys as well.

Thanks in advance for the help.

Last edited: