Tommy is going to have the engine together next week, Greg at ZZ has finished the cylinder heads , and the porting is unreal. Greg has been putting in the extra hours on the flow bench , and conferring with Big Al , on the flow bench. Ill post a few pictures of al’s creations , one day , like a carving a head out of solid cast iron for a inline Chevy six , but that a long story , involving me flying to the GM foundry in Toluca Mexico , and having them cast me a few heads with out ports or water jackets , 300 lbs chuncks of cast iron. This was for a comp engine program, that made about a 100 hp more then any I 6 out there.

I think the numbers were 675 @ 9000 rpms or so on gasoline , all this from a 265 inch engine

Back to the Z28 Tyler and his buddy’s are working hard on getting the car together , and the results are going to be stunning , the 10.5 tire is going to be fun , but I like cars to leave with the wheels 3 feet in the air .

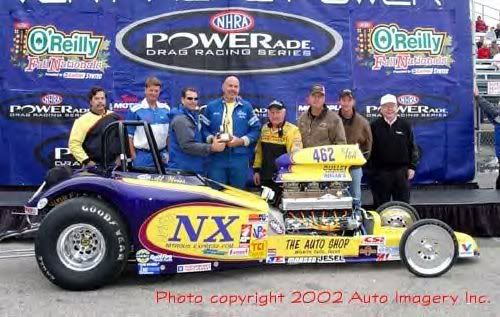

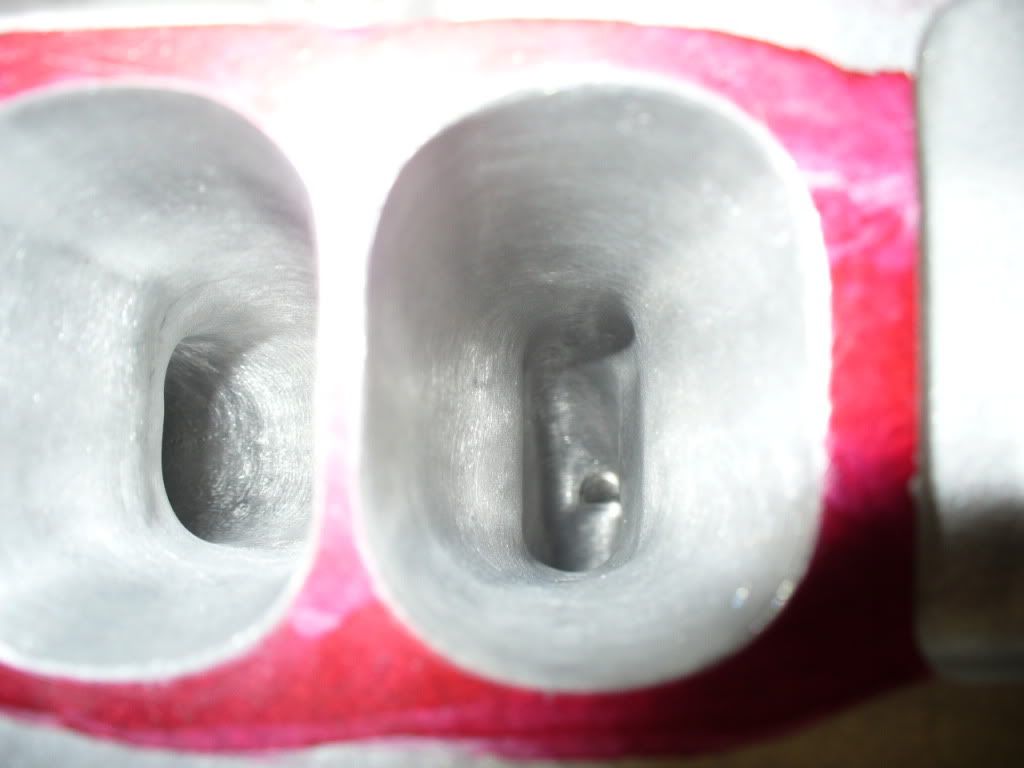

Here is the car getting best engineered at Dallas , and a picture of Big Al and the head .

There was a lot of secrecy about this head and motor program, we were accused of running nitrous , and later cleared , but now with the motor sold , a few pictures will not hurt .

that work bench is where Al assembled the splayed valve Chevy V6’s that I ran in comp, as well as the intricate parts of Eddie Hills top fuel dragster program. Al was the Crew Chief on Ed’s program the last year , and has worked behind the scnes for the last 30 years with Eddie

this just to let you know where some of the best DMax engines in the country will be coming from in the future , Al , Tommy and group are gearing up to produce the very best , and from past perfromances , I will tell you that its going to happen

notice the black parts under the ports , that is where Al carved a water jacked so to say , the rules are that you could do anything as long as the valve cover rail remained stock