COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

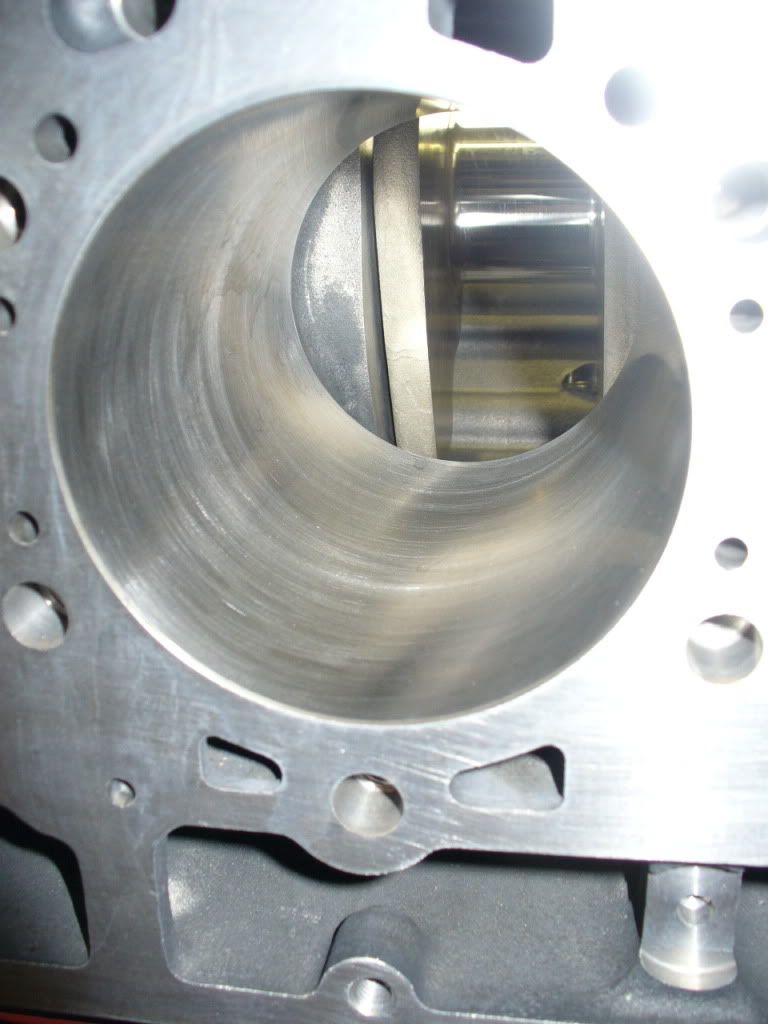

I know what you mean, this is the place where I learned my craft in racing . Al and Tommy are hard core engineers in developing engine programs . They are developing the Dmax engine platform . One of the keys aspects , is molding the power output to better fit the intended use. One example is re powers. The Re power movement is going crazy , there are quite a few engine build ups coming in the door