madmikeismad

So mad

- Joined

- Dec 19, 2009

- Messages

- 14,347

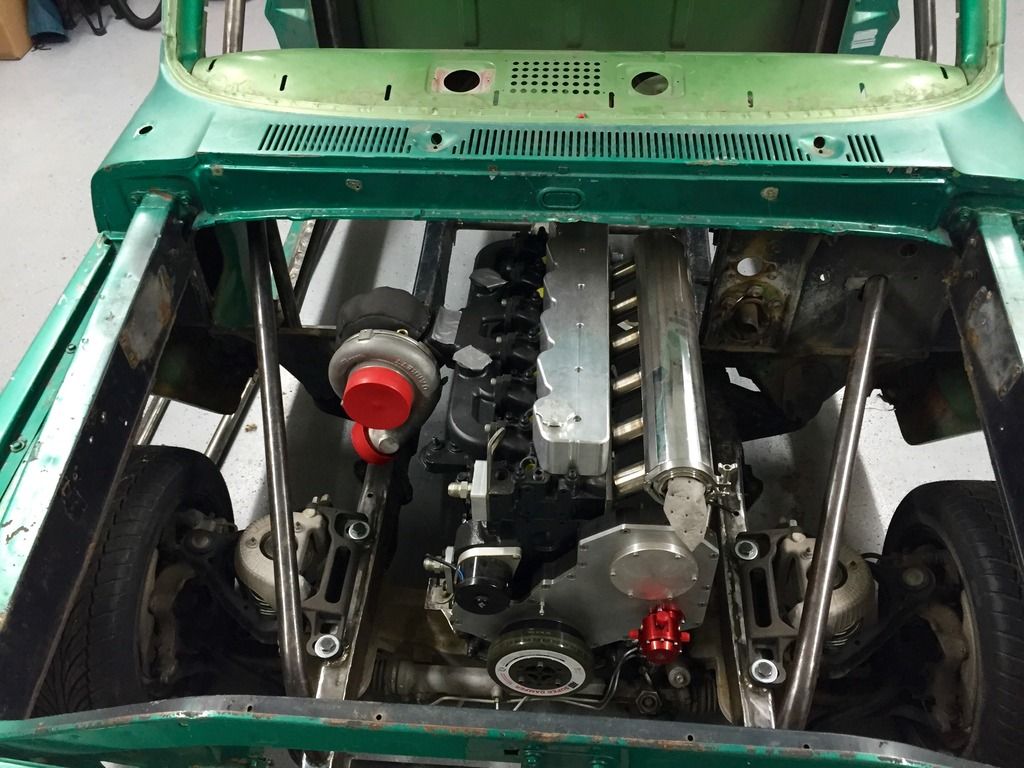

or Dry sump?

Oil pan on the ground? Are you going to section it and kick it out to the sides like the gassers do for capacity with clearance?

I thought about doing that at first. I don't plan on it anymore. With a 3 gal oil capacity I think it is way over kill for a drag truck. Maybe down the road if I get better with aluminum tig I'll make a winged moroso looking thing.

Its not the oils quality thing... its the oil staying up top in the engine and running the pump/better end dry...

We reduced our oil capacity but had to add a Moroso oil accumulator. At the end of the 1/4 when we were on the brakes hard our oil pressure would drop. We added the accumulator and our issues were solved.

Made a big difference. The one we run is the 2qt one.