One can hardly be faulted for taking your response to my correction as snubbish... internet forums, of course, are primarily a medium of the written word, but in the event of word failure, smilies can be of assistance.

For instance, you probably meant to say:

"We all can't be as smart as you Lazar.:bow:"

Then, even I could've recognized the compliment.

So.... Thanks!

Also, please feel free to use my given name, just like the rest of my friends do.

Inferiority issues include articulation, strength, load capacity, handling, adjustment, ride quality, durability, aesthetics, etc.

No doubt all the folks who are using them could provide many anecdotal recommendations for them.

Interestingly, I don't remember 4-link suspensions brought up yet, as the topic title of this thread hints.

They are the among the best of solutions, but the leaf packs must be binned.

My personal favorite is a 3-link with a Watts linkage... that's what we'll be putting in the rear of the trailer queen (oh my, that sounds risque! :hehe

.

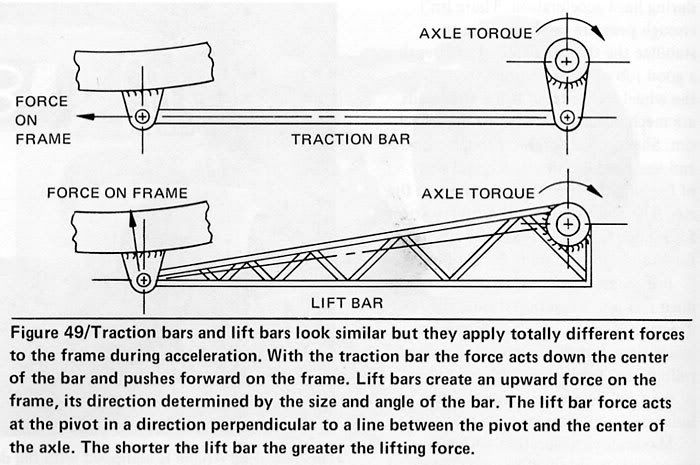

That location is popular with the pullers (mostly due to the inertia of convention), since it lifts the front end more than short bars (which lift the rear frame over the axle), so the rear tires have greater initial traction to get the sled rolling towards higher wheel speeds before the pan hits hard.

Our '05 full-pulled with extra-short bars (just to prove a point), but lighter trucks can certainly benefit from long bars, as long as the beam length & cross-sectional strength doesn't allow Young's modulus to propagate buckling under full power.