M_Thomas07

CompDEX

- Joined

- Aug 4, 2010

- Messages

- 1,315

Pretty sure you've been "one upped":stab:.

...yes I am this bored:doh:LOL.

Umm... if your gif is broken pretty sure your still treed. Lets go to chat if you're bored...

Pretty sure you've been "one upped":stab:.

...yes I am this bored:doh:LOL.

I bed at 70psi your right at 1 to 1 boost drive pressure.

BOOST CONTROLLERS

The incab is nice cause you can tune from the drivers seat. That's what I got. Very simple and super efficient

Sent from my Galaxy Nexus using Tapatalk 2

How is this plumbed in? Is it venting boost or being used like an adjustable boost elbow?

Using a gate source in between the top and bottom charger. Will delay gate opening till there is primary pressure.

Not trying to be an A$$ but, how can you assume his DP's are a 1 to 1 ratio @ 70lbs of boost with out a DP gauge? I can hit 70lbs of boost, but I also will see 100lbs. of DP the higher the RPM's go up..

Just asking..

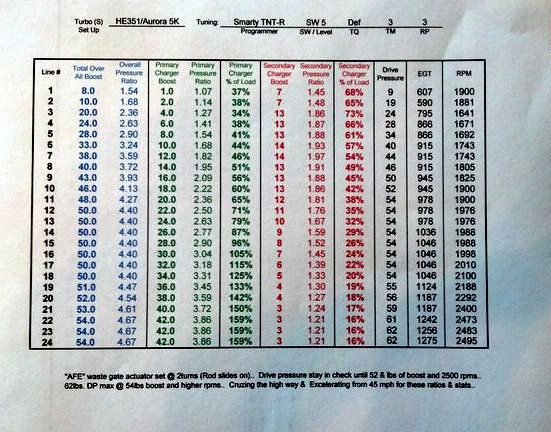

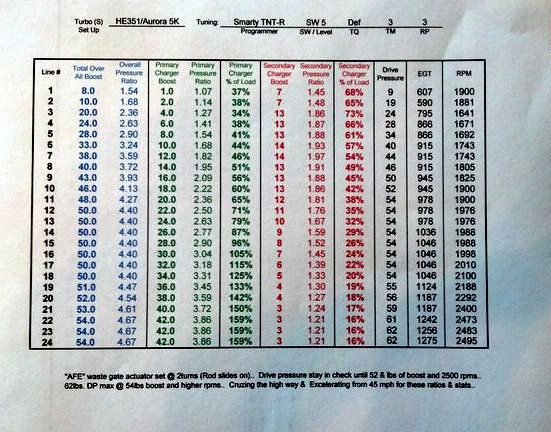

Great advise on the in cab boost controller.. Just to add some more info.. I installed one of "AFE's new WG Actuator (40lbs.) and it really makes a big difference in controlling the WG over the OEM actuator.. OEM actuator allowed to much creep..

I have a smooth consistent opening of the waste gate and a consistent average of DP and Boost until higher rpm's..

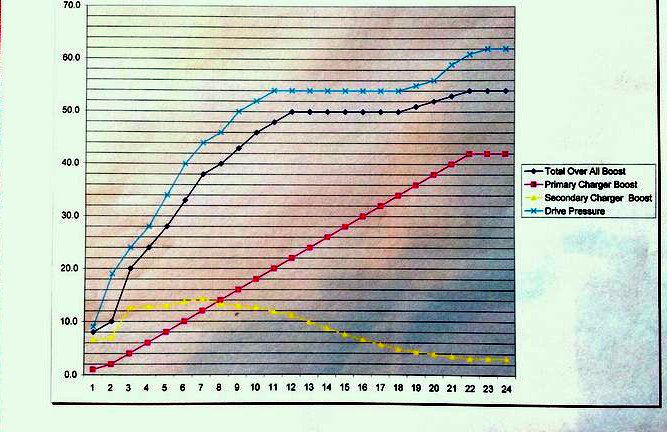

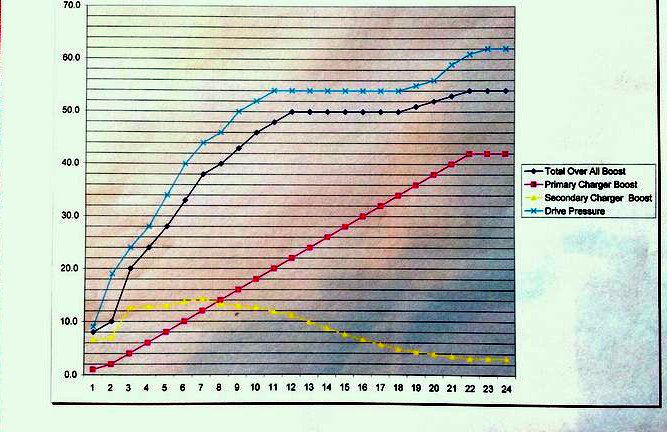

For reading the chart, boost on the left and the bottom numbers correlate to the line number on the spread sheet..

A couple guys here have tried it. It doesn't work as well in practice as it does in theory. I don't believe anyone has continued to use such a set-up.

I have always wondered about claims of boost and drive being equal at a certain boost level. maybe at a certain rpm but if you are 1 to 1 at 1800 you probably are not 1 to 1 at 3800. and if you are 1 to 1 at 3800 you probably aren't making boost at 1800.

I agree but most setups I have seen like his have been very close to 1-1 at full boost

here you go. both chargers are doing 50% of the work. how do they run on the truck? egts? if your wanting more boost i would work the primary harder but it looks good on paper.Ok so here's my set up:

Ford 6.0L with 285cc/150% injectors.

dual hpop's

ED. billet 63/68/.70 (12cm) over a FI S482/92/1.10

The secondary is wastegated with a spring style actuator. (Which I believe, the spring is too stiff)

I have a Sound Performance Quick Spoool Valve on the 82mm that starts to open at 8 psi. (referenced from the 82mm's output boost)

Cruising down the highway, 75mph, and roll into it so it doesn;t down shift, I have this:

100 psi drive pressure to the secondary. (63mm)

50-55 psi drive to the primary. (82mm)

Only got 20 psi coming out of the 82mm for boost.

Total boost pressure to engine is 65psi.

Can someone figure out the ratios for me, and what I need to do please?

I think I need either a bigger housing on the T3, so a divided .80 or even an open .80....or try a lighter spring in the wastegate actuator so it opens up sooner.

...thoughts?

i agree 100% that you need to work the primary harder. 20psi out of that charger is doing hardly anything. if you can get it to around 28-32, i can almost garantee total boost will be around 75psi and drive will be well under 100psi as well as cooler egts.Ok, so now I'm confused all to hell...

I was thinking I needed to get the "overall" drive pressure to match the "overall" boost pressure? (1:1)

If I have 100 psi drive, and only 65 boost...isn't that a chitty ratio? (1.54:1)

Temps were 1550*F just before I backed out of it.

I just don't think the primary is even working hard yet...

On my last set up, 66/71/80 over a S480/96/1.32 I have the same 100 psi drive, but the 80mm was putting out 30-35psi...

How can the bigger turbine wheel and housing, (96/1.32) with an 80mm wheel, and smaller injectors, 225cc/100%...put out more pressure/volume then the 92mm/1.10 housing, and a 82mm wheel?

If I can get the wastegate to open sooner, and drive the primary up to say 30 psi output...what would the numbers look like then?

I know the drive pressure would prolly drop down to around 75-80psi, but I don't know what the total boost would be...

And thank you for the chart!!

Whynot try it without the spool flange?Ok so here's my set up:

Ford 6.0L with 285cc/150% injectors.

dual hpop's

ED. billet 63/68/.70 (12cm) over a FI S482/92/1.10

The secondary is wastegated with a spring style actuator. (Which I believe, the spring is too stiff)

I have a Sound Performance Quick Spoool Valve on the 82mm that starts to open at 8 psi. (referenced from the 82mm's output boost)

Cruising down the highway, 75mph, and roll into it so it doesn;t down shift, I have this:

100 psi drive pressure to the secondary. (63mm)

50-55 psi drive to the primary. (82mm)

Only got 20 psi coming out of the 82mm for boost.

Total boost pressure to engine is 65psi.

Can someone figure out the ratios for me, and what I need to do please?

I think I need either a bigger housing on the T3, so a divided .80 or even an open .80....or try a lighter spring in the wastegate actuator so it opens up sooner.

...thoughts?

Ok..Nother question...

Why, with 50psi of drive pressure to the primary, is it only putting out 20psi?

That is a chitty drive to boost ratio for a turbo...

And when you guys say that when it hits 35-40psi, the gate should open...how do you set it when you have 100psi on the one side of the gate pucks, and 50on the other?

Wouldn't that be 50psi acting on the gate pucks trying to open them? (and I still don't think they are open at that pressure.)