SCHOOL BUS

DLRA T-O

- Joined

- Jun 27, 2007

- Messages

- 10,513

Does arp have rocker studs? How much them little suckers run

the inner base circle of the camshaft.

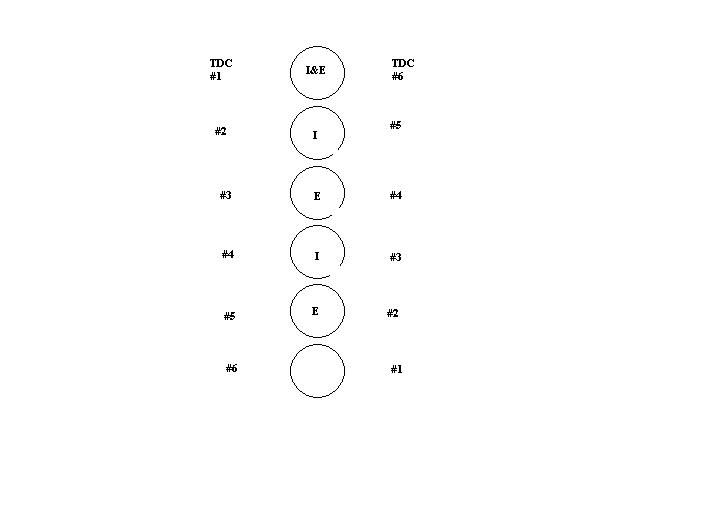

or you could just do it the way its listed on pg 1?

adj the int when the ex for that cyl starts to open and adj the ex when the int for that cyl starts to close

its actually more accurate to adj them this way

a 2 position method is easy, but what do you want?

easy or accurate?

with the 2 position method it is possible for 2 of the valves to be slightly on the ramp

in ea position...

so you stand the chance of having 4 loose valves

or do it as above and you know they are all correct

good luck with it, don

Man Bus, this is weird. When Relentless adjusted the valves the last time did they mention that one rocker was out more than the rest?

It would be really strange to have them all out of wack?

If it's only one, as said earlier in your thread, it has got to be a cam lobe or valve seat.

well last time i went in chris' helper did it cuz was busy and i was in a hurry so he didnt get to look at it, but i remember the guy saying it was more than one. chris said to see how long it goes and the next time we will start doing different things to figure it out.

how does one check the valve seats. and how are they repaired

Its safer to fix a valve seat before it drops off into the motor!!!!:bang

man you gotta run faster than me cody....youre gonna run out of excuses here sooner or later :hehe: