Flatblack79

Just Ignore Me

- Joined

- Jun 23, 2012

- Messages

- 276

Did you try the little trick i told you about?

Having a shop is nice but you just seem to collect more stuff than you really need.

Got that right. We have a 16x24 above ground "work shop" that was supposed to be just for building engines... that lasted for like 3 weeks, now we cant hardly walk through the damn thing.

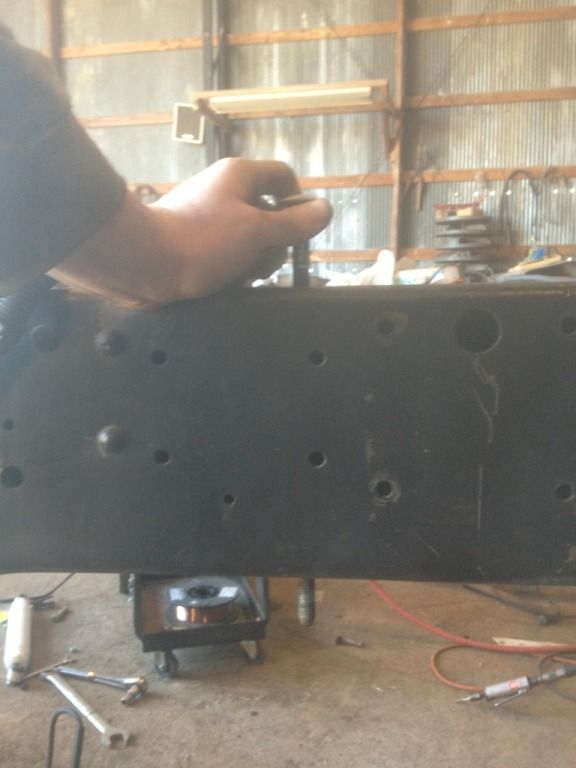

Looking good Matt going a stout frame

Dale

Welds look good. You using a mig or tig welder?

Damn those look good for a mig weld!

Damn those look good for a mig weld!

Um...not criticizing the op...but you ^^^ need to open your eyes! A good MIG weld is every bit or better looking than TIG.

Um...not criticizing the op...but you ^^^ need to open your eyes! A good MIG weld is every bit or better looking than TIG.