ok here is the truth about rail pressure and this might shed a different light on what is going on , I spent 8 hours on the dyno yesterday at Dr Performance , thank you Kenny for the use of the dyno and the nitrous.

We made a lot of pulls and I want to thank Burt Daniels for the fact that his, rebuilt in the truck, in the middle of the night short block , needed after I toasted all the pistons the weekend before Drag Week , held up to a hell of a beating .

He and James Role the service director , do a lot of support work ,and make sure I get to the track with the busy schedule and multiple projects that I have going at anyone time .

I have been advised to delete some graphs on the data log sheets, and that is all I will say about that

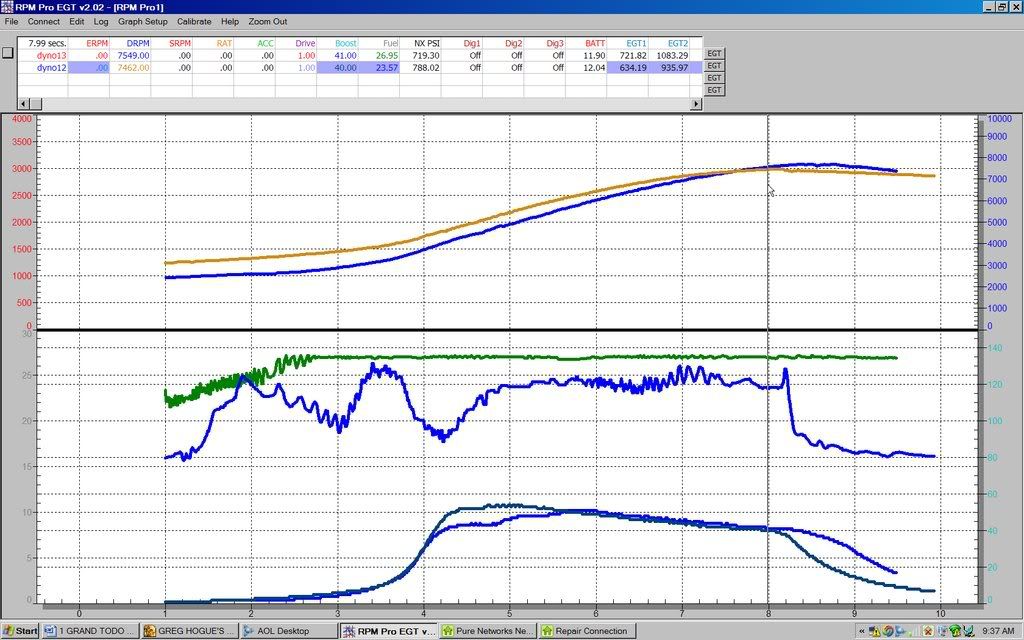

Here are two pulls both with the Smarty TNT REVO R on 5 rail pressure on max. The only difference is the DR performance module

the NX was a .125 jet with 900 psi bottle pressure. on both

The bottom most graph is boost, max with the silver bullet 72 is 52 psi with 47 drive pressure

Up from that is Rail pressure, the max resolution of the sensor is 27,000. Anything about that is a flat line I have a 35,000 psi senso coming .

The blue graph is the Smart on 5 with max rail pressure and no Dr Performance and the green graph is with the Dr Performance race box

If I turn the Rail pressure to Stock on the smarty , and turn the Dr Performance box on the results are the exact same

This is with 54 liter per min injectors and the new Industrial injection stage II pump.

All this about draining the rail has been related to software. I can turn the smarty to 9 and with these huge injectors it still maintains rail pressure, but the locomotive smoke, just chokes the life out of any kind of acceleration.

The 1 and 3 levels were identical and layer one graph on top of another identical.

Just as in carburetors on race engines you have jets and bleed, and, on the high end competition eliminator carburetors where we have to retain stock appearance. We find ways around the quirks and down falls with a lot of engineering

the lines on the top are wheel speed , at over 150 mph with 4.33 gears and 28 tall tires