You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Single CP3 Shootout, whos gona make it?

- Thread starter wap

- Start date

Turbo Charged

Banned

- Joined

- Oct 1, 2008

- Messages

- 20

I am ready, I wish we can find a neutral place. II wants it to be at their place because they think they are the only ones that can do accuarte testing and thats not so. It's like a dyno here reads high and another one reads low, it doesent matter as we are all on the same machine on the same day, Lets GO!!

John

Same machine, and All your best pumps, Same day, Whats the difference! Why not use II's Test Stand?

WICKEDDIESELS

SUPPORTING VENDOR

- Joined

- Dec 31, 2006

- Messages

- 867

I am in Virginia, centrally located is not Utah!

More like Illinois, or Missouri

More like Illinois, or Missouri

Turbo Charged

Banned

- Joined

- Oct 1, 2008

- Messages

- 20

ok here is the truth about rail pressure and this might shed a different light on what is going on , I spent 8 hours on the dyno yesterday at Dr Performance , thank you Kenny for the use of the dyno and the nitrous.

We made a lot of pulls and I want to thank Burt Daniels for the fact that his, rebuilt in the truck, in the middle of the night short block , needed after I toasted all the pistons the weekend before Drag Week , held up to a hell of a beating .

He and James Role the service director , do a lot of support work ,and make sure I get to the track with the busy schedule and multiple projects that I have going at anyone time .

I have been advised to delete some graphs on the data log sheets, and that is all I will say about that

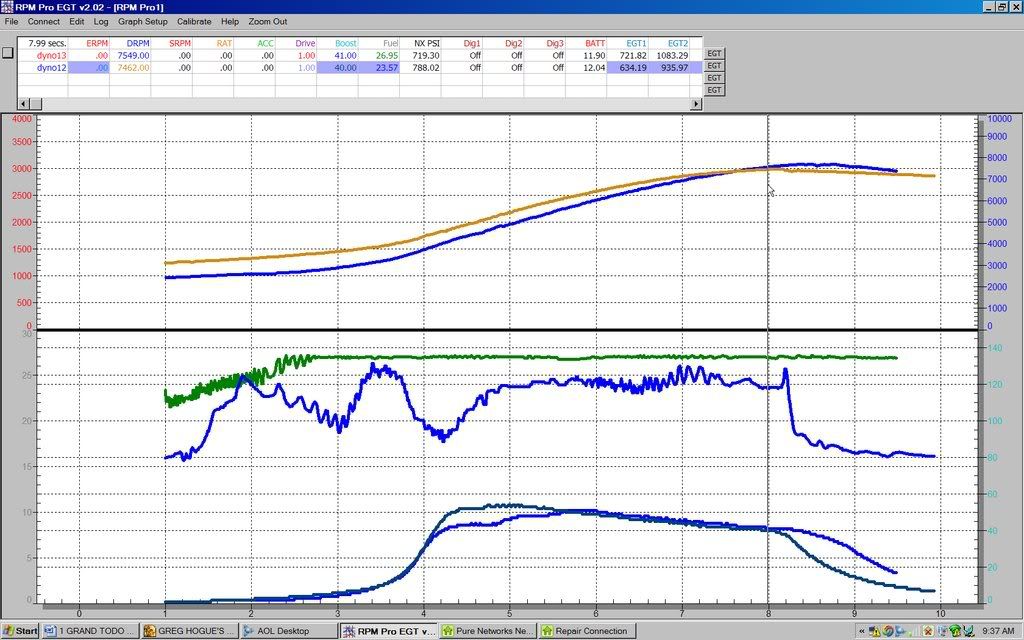

Here are two pulls both with the Smarty TNT REVO R on 5 rail pressure on max. The only difference is the DR performance module

the NX was a .125 jet with 900 psi bottle pressure. on both

The bottom most graph is boost, max with the silver bullet 72 is 52 psi with 47 drive pressure

Up from that is Rail pressure, the max resolution of the sensor is 27,000. Anything about that is a flat line I have a 35,000 psi senso coming .

The blue graph is the Smart on 5 with max rail pressure and no Dr Performance and the green graph is with the Dr Performance race box

If I turn the Rail pressure to Stock on the smarty , and turn the Dr Performance box on the results are the exact same

This is with 54 liter per min injectors and the new Industrial injection stage II pump.

All this about draining the rail has been related to software. I can turn the smarty to 9 and with these huge injectors it still maintains rail pressure, but the locomotive smoke, just chokes the life out of any kind of acceleration.

The 1 and 3 levels were identical and layer one graph on top of another identical.

Just as in carburetors on race engines you have jets and bleed, and, on the high end competition eliminator carburetors where we have to retain stock appearance. We find ways around the quirks and down falls with a lot of engineering

the lines on the top are wheel speed , at over 150 mph with 4.33 gears and 28 tall tires

If im looking at this graph right, a little after 4 seconds into the pull there is about 10,000 PSI Rail pressure difference, between the Smarty on top RP setting and the Smarty with no RP, stacked with a dr p box.

Smarty@ full RP is about 17,000 PSI @ 4 seconds

Smarty with no added RP/ stacked with a DR.P Pressure box is about 27,000PSI @ 4 seconds.

Thats a huge Difference, Wow!

I wonder if the Timing and Duration Offer the same results When trying to be adjusted?

Comp461, did you mess with the other adjustments? If so what were the results?

Turbo Charged

Banned

- Joined

- Oct 1, 2008

- Messages

- 20

Is the bottom graph a HP graph? or boost?

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

the bottom is boost , the top is drive line speed ,

you correct on the rail pressure its right at 10,000 psi

in the past people would blame the pump, but here is the last word.

Kevin at Dr Perfromance worked out this module , and it works

you correct on the rail pressure its right at 10,000 psi

in the past people would blame the pump, but here is the last word.

Kevin at Dr Perfromance worked out this module , and it works

JOESHTRDDSL

Nothing Special

- Joined

- Jul 1, 2008

- Messages

- 964

What module is that from Dr. Performance if you don't mind me asking. Is it the same on that anyone can buy.

jlibert

New member

- Joined

- Jun 28, 2007

- Messages

- 3,454

What module is that from Dr. Performance if you don't mind me asking. Is it the same on that anyone can buy.

Yeah, I talked to comp about the box a while back. He told me to call Dr.P and just tell them you want the same box that Greg (project x) has.

he also referred to it as a "chop box". Seems like it would be worth a shot.

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

call Kevin at Dr Perfromance 817 341 0127

its a fuel boost module , its a mirco processor and Kevin programs it for what we are doing , its make a huge differance ,

they work with quite a few people , but most don't really let the cat out of the bag

its fixes the problem , and it didn't matter if I ran the Smarty on full killer rail, or stock rail , the results were the same on the datalogger,

great way to run a easer setting on the street and flip it on when you need power , it has a control switch if you want

its a fuel boost module , its a mirco processor and Kevin programs it for what we are doing , its make a huge differance ,

they work with quite a few people , but most don't really let the cat out of the bag

its fixes the problem , and it didn't matter if I ran the Smarty on full killer rail, or stock rail , the results were the same on the datalogger,

great way to run a easer setting on the street and flip it on when you need power , it has a control switch if you want

Sounds just like a TS MP8 to me.

that's what I was thinkin :bang

inline6359

Microwaving cats since 01

- Joined

- Aug 28, 2006

- Messages

- 2,043

And how did you do, I didn’t see you there any where .

The truck made more power, it broke things , and Zach and I fixed them , and fixed then and fixed them and finished the event.

This was the first pass , rolled the tree stating the timer, and then I launched , so this would have been a lot faster , by mine and Charlie’s estimate , about 8 tenths . This was with half the nitrous I normal start with, .090

The last day , I did the same with 129 mph and again I ask where were you ,

http://www.youtube.com/watch?v=8zX9oQSP1PQ

WOW the one event you attended...:clap:

And the only diesel..:rockwoot:

Your my hero!

Diesel Power

Not Wade Moody- The Original Diesel Power

- Joined

- Apr 28, 2006

- Messages

- 229

Now I know I'm a dmax guy but I happen to have a pair of II Cp3's on my truck. last season (2007) i ran the same dual cp3 kit with 2 stock dmax cp3's. The truck ran well but wouldn't hold rail pressure. it usually would hang around 20k, 18k if the fuel was really hot on a hot day and i was running it more than once.

during the off season i sent my pumps to II and had them do whatever they do to them. I'm running the same tuning (tts), injectors (tts), and dual cp3 kit (tts) this year as last and all year was able to hold 25k+. Even at DHRA in Utah this year i pulled 3 times in a fairly short period of time and every pass held commanded pressure. I don't know how much more fuel we could add via programming before they would be inadequate but I can say that in my case they most definitely did solve my low rail-pressure problems.

I datalog every run so i've got a pretty accurate log of every run i've made over the last couple years.

I don't care to get involved in the politics of this.. it reminds me of tranny wars of years past, etc. but since i do have first hand personal experience with stock and II modified pumps i wanted to add my 2 cents.

during the off season i sent my pumps to II and had them do whatever they do to them. I'm running the same tuning (tts), injectors (tts), and dual cp3 kit (tts) this year as last and all year was able to hold 25k+. Even at DHRA in Utah this year i pulled 3 times in a fairly short period of time and every pass held commanded pressure. I don't know how much more fuel we could add via programming before they would be inadequate but I can say that in my case they most definitely did solve my low rail-pressure problems.

I datalog every run so i've got a pretty accurate log of every run i've made over the last couple years.

I don't care to get involved in the politics of this.. it reminds me of tranny wars of years past, etc. but since i do have first hand personal experience with stock and II modified pumps i wanted to add my 2 cents.

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

WOW the one event you attended...:clap:

And the only diesel..:rockwoot:

Your my hero!

you would be wrong , I ran Vegas the last part of the year in Super Gas running 8.37 @ 169

I ran Denvor in Super Street in Project X , and 3 land speed evnts setting 3 land speed records that still stand

the bottom is boost , the top is drive line speed ,

you correct on the rail pressure its right at 10,000 psi

in the past people would blame the pump, but here is the last word.

Kevin at Dr Perfromance worked out this module , and it works

Hey Greg,

I think I might be missing your point here.

I understand the bit about the electronic tuning being able to make good use of the available pressure, but wouldn't 24kpsi make more power than 10kpsi with the same setup?

If so why wouldn't you use a larger (or another) CP3?

Not trying to start a fight....Just trying to learn something.

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

Hey Greg,

I think I might be missing your point here.

I understand the bit about the electronic tuning being able to make good use of the available pressure, but wouldn't 24kpsi make more power than 10kpsi with the same setup?

If so why wouldn't you use a larger (or another) CP3?

Not trying to start a fight....Just trying to learn something.

Not sure what you mean, the graph shows the same exact tune with the same amount of Nitrous,

This is two runs laid on top on each other, I have heard how people are draining the rail, and they see their gauges drop with a certain tune. Well this graph is a Smarty REVO TNT R on level 5 with the rail pressure set of Extreme # 4 .

People have use the fact that with big injectors their pumps can’t keep up , and drop to below 20,000 lbs to say a pump will not keep up and is not big enough .

The problem is if you will look at the data logger graph you see that the rail pressure drops to around 17,000 psi . Most would have use this data to order a bigger of second pump .

I have always thought that the true problem was not the pump but the software , I use , and have been using a Dr Performance fuel boost box, and the results were instant almost 100 hp stacked on top of the same tune . And Rail pressure was up to the top of the resolution of the sensor. There is almost 10,000 lbs of difference is rail pressure, this should change the way people are looking at this entire subject.

I have watched as Kevin takes a stock truck and puts a smarty , and Dr performance module stacked and make 500 + hp instantly , and maintained rail pressure . Take this farther and do the basic addition of a stage 2 pump, and a SB62 turbo and 650 hp is ready to crush a transmission.

JOESHTRDDSL

Nothing Special

- Joined

- Jul 1, 2008

- Messages

- 964

I installed my Dr. Performance preditor 2013 last night. The rail pressure when I am hard on it hits 26.9k, but when I get up in the higher rpm the rail pressure drops down to 12k. It also pops 3 or 4 times if I stab the throttle from a stop and then takes off. The cp3 can't keep up at initial WOT and it won't keep up with demand at higher rpm. I will be ordering a stage 3 soon. The Dr Performance box is deff. an agresive box and works well. Joe

WICKEDDIESELS

SUPPORTING VENDOR

- Joined

- Dec 31, 2006

- Messages

- 867

Obviously programming and injector sizing affects rate of consumption. If you are locked in overdrive at low rpm and nail the throttle, it will take a small amount of time to build pressure. What your graphs show is very exaggerated in comparison to what most see.

My truck weighs 7596lbs, with 1/2 tank of fuel. On the interstate at 70, I am at 1700 RPM, with a 3.73 and 37" tall tires. With the Smarty on 7, if I tip into the throttle it will initially drop rail pressure, then the gauge comes right up. If I nail the throttle, even with the converter staying locked, it will immediately climb past 20,000 to what is commanded using the Smarty. That is with the RP on the Smarty set to level 1. That is with a relative decent sized injector. If I turn the MP8 up, it comes up even quicker.

The true test of a CP3 is to provide fuel very close to 1:1 with what the ECM is asking for. My CP3 will usually set a high rail pressure code on low programming levels, as it provides more flow than can be consumed.

This is the measure of the additional fuel capacity to the rail. With the right product, you don't need special programming to get rail pressure, you just need a capable pump.

Having to "TUNE" up the pump, shows lack of its capability, having to tune down a pump indicates significant reserve capabilities.

My truck weighs 7596lbs, with 1/2 tank of fuel. On the interstate at 70, I am at 1700 RPM, with a 3.73 and 37" tall tires. With the Smarty on 7, if I tip into the throttle it will initially drop rail pressure, then the gauge comes right up. If I nail the throttle, even with the converter staying locked, it will immediately climb past 20,000 to what is commanded using the Smarty. That is with the RP on the Smarty set to level 1. That is with a relative decent sized injector. If I turn the MP8 up, it comes up even quicker.

The true test of a CP3 is to provide fuel very close to 1:1 with what the ECM is asking for. My CP3 will usually set a high rail pressure code on low programming levels, as it provides more flow than can be consumed.

This is the measure of the additional fuel capacity to the rail. With the right product, you don't need special programming to get rail pressure, you just need a capable pump.

Having to "TUNE" up the pump, shows lack of its capability, having to tune down a pump indicates significant reserve capabilities.