Dazed&Confused

Surfing my own world

- Joined

- Jun 27, 2006

- Messages

- 2,533

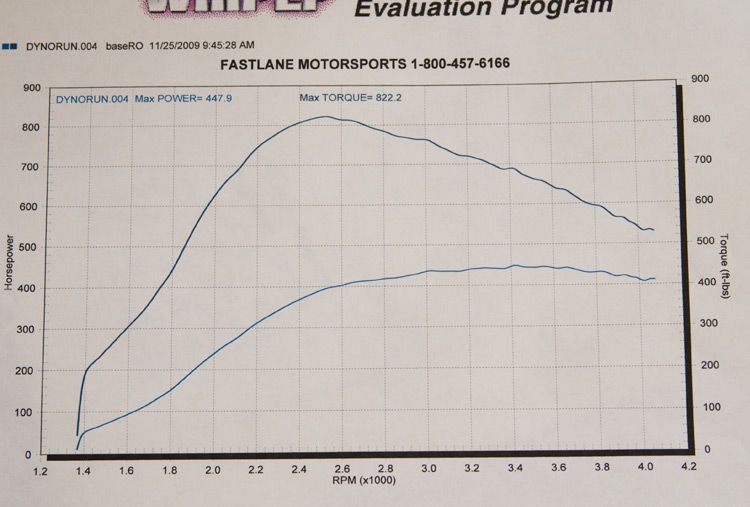

I want to be full boost at or before 2800 RPM. I've yet to see a dyno graph where a VE makes power higher then 3000RPM. I like the idea of boost right off idle as well. I have no interest is spinning mine more then 3200 rpms