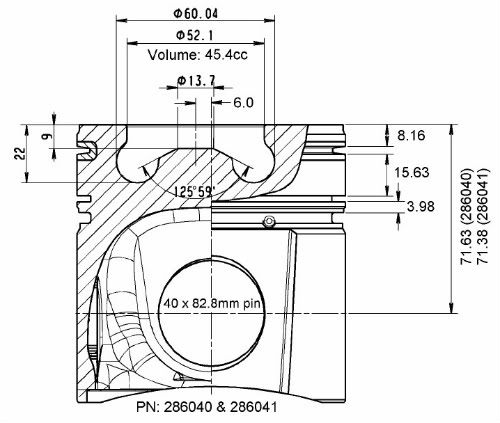

Stock piston, pin, and rings out of the 95', these are #286040 pistons with 71.63mm from center line of pin to top of the piston & 45.4 cc bowls.

They weigh 1967 grams.

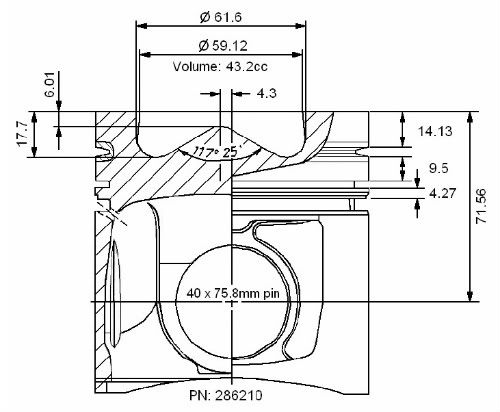

Here is the 91' non intercooled used piston #286210 complete with piston, pin, and rings, it weighs

1810 grams which is exactly 157 grams less weight.

I opened up the bowls on the 7x10 mini-lathe from 59.12mm to 71.50mm with a roughly 8.5mm deep cut at a 30* angle.

Stock 91' non/IC piston with .005" cut off the top for comparison:

Now for a little math. Assuming the stock pistons were exactly 17.5:1 compression ratio:

+.010" headgasket or +.254mm = roughly 2.08cc's or a decrease in compression ratio of

-0.626:1.

Opening up the reverse taper in the bowl to straight or opening up the 59.12mm top half to 61.4mm for 8.56mm deep = roughly 1.01cc's or a decrease in compression ratio of

-0.287:1

Opening the bowl edge out to 71.50mm to a positive 30* = roughly 4.44cc's or a decrease in compression ratio of

-1.157:1

Removing .005" or .127mm from the tops of the pistions = roughly 0.66 cc's or a decrease in compression ratio of

-0.158:1

Going from #286040 pistons with 45.4cc bowls to 286210 pistons with 43.2cc bowls while accounting for the lost piston protrusion of roughly 0.07mm equates to a loss of 1.63cc's for a

gain in compression of 0.397:1

All said and done, the compression ratio on this motor now calculates to

15.67:1 with the .010" oversized head gasket.

Or 16.21:1 with a standard thickness head gasket.