ENafziger

New member

- Joined

- Oct 22, 2008

- Messages

- 843

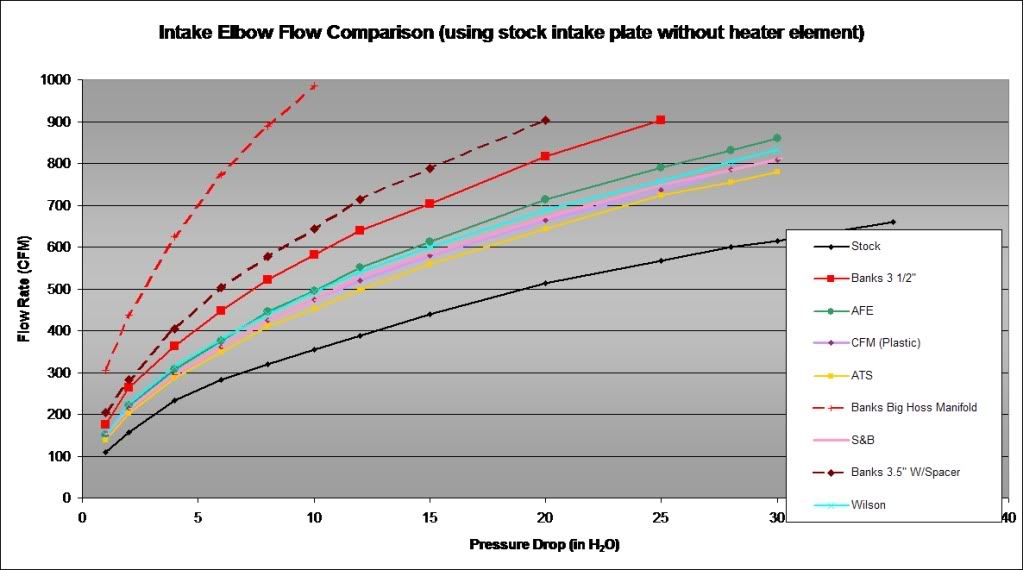

The graphs above were put together by our engineering team and were never used by our marketing department. Please try again

Wow, thanks for the data!!! Extremely helpful...

By the way, that dyno cell looks extremely clean and well layed out! Yes, I've toured the labs at Detroit Diesel, and they're no where near what yours looks like!