MAXTORQ

Drop by, beers on me !

- Joined

- Apr 11, 2007

- Messages

- 1,566

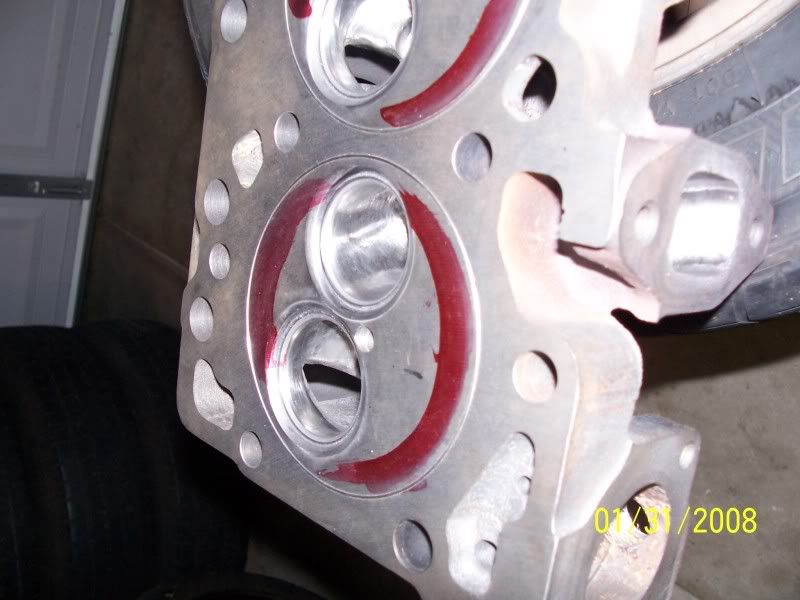

Question: Why did you apply paint on the inside of the head and plenum? I'd be leery of the paint flaking off from the multitude of heat cycles......

It was cleaned prior to the manifold being installed.