Diesel Freak

Active member

- Joined

- Jun 20, 2007

- Messages

- 1,163

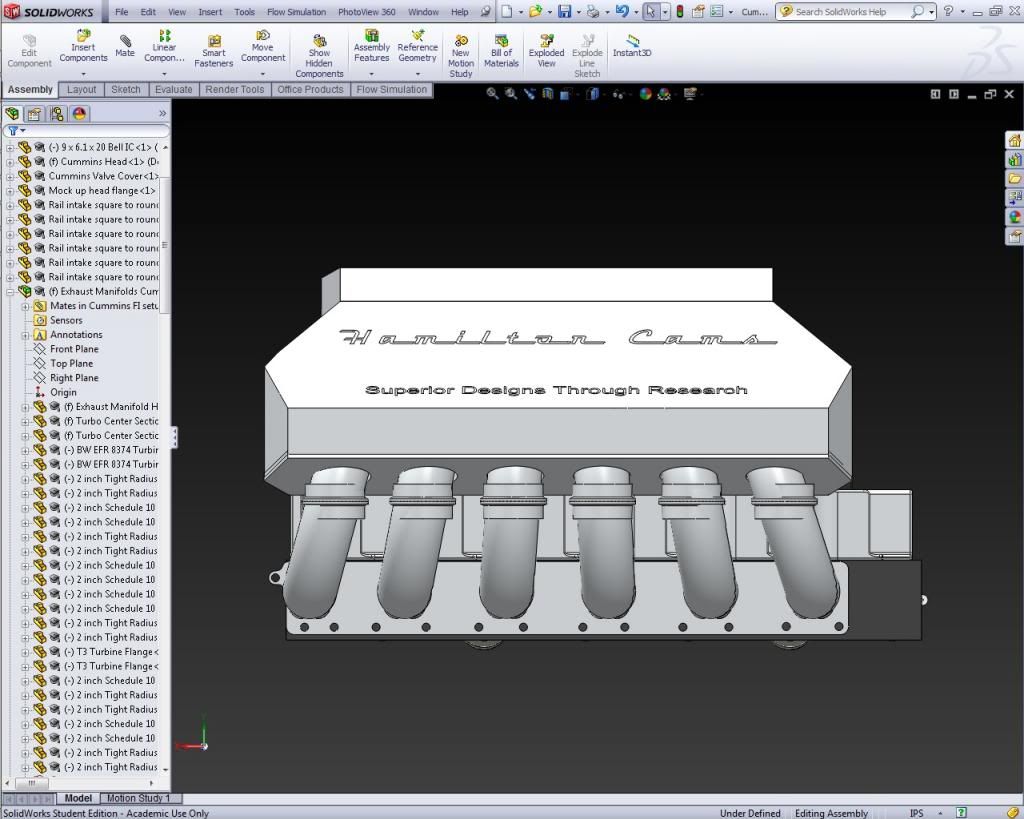

Another thing to note in terms of what duration to use, for competition Cummins flat tappet cams, they range anywhere from 260-340 degrees of open time at the valve. Just having a calculated correct length will not take you very far if you start with flawed data. Also, not to pop your bubble, but all of the engineering papers I have read on the subject state that since air is like a spring, there are always resulting pressure pulses that cannot be accounted for, so all of the calculating will get you in the neighborhood and functional testing will take you the rest of the way. If you do get the pressure wave to hit the intake valve at the right RPM, it will magnify the effect if you get the valve off it's seat faster to take advantage of it..........

This is my thinking also...wish I had the time to play with it...but cant quit the day job for at least another 30 years...

just a question, with 340 degrees of open duration, how are you eliminating flow reversion???

The cam in my KTM has no where near that...closer to 240...and that engine spins to 9k...

I know you make cams...so, you will also understand this, rocker arm ratio does not affect duration...if lift at the lobe is zero, then even 1.7 x 0 still equals zero

Last edited: