You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mis-Matched? No longer.

- Thread starter JasonCzerak

- Start date

JasonCzerak

Active member

- Joined

- Aug 10, 2006

- Messages

- 14,826

scat. Not sure. Might have to see if Cory responds with a number.

----

Rods ordered. Small fortune spent.

Stock MLS gasket is going back in I'd imagine since it held up very well

Rings...... What does everyone say about the rings? the z-gap ones are not hurt. Run them?

----

Rods ordered. Small fortune spent.

Stock MLS gasket is going back in I'd imagine since it held up very well

Rings...... What does everyone say about the rings? the z-gap ones are not hurt. Run them?

Fullboarcummins

Full Boar mobile dyno

- Joined

- Nov 24, 2011

- Messages

- 148

I don't remember the exact gap Jason. Full Boar will have it on file. I went on the higher side of the tolerance.

paulb

New member

- Joined

- Jul 14, 2006

- Messages

- 1,673

Jason, didn't you post that your coolant level was down a couple inches in the rad after a hard run. Were you still having that happen?

I don't have any experience with the z-gap. I run total seals and have not had a problem with them yet.

Paul

I don't have any experience with the z-gap. I run total seals and have not had a problem with them yet.

Paul

Joesixpack

Pull'n it.

- Joined

- Apr 4, 2008

- Messages

- 4,118

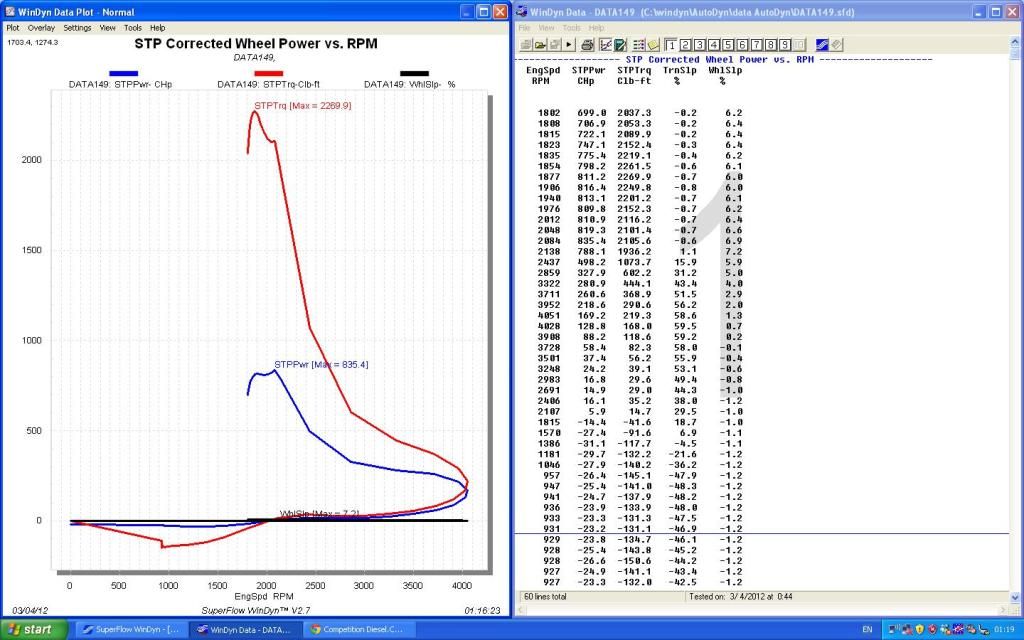

So this graph.

1400 is too much at those RPM ranges?

Going back here's where the SSR was tuned at based on my post with that graph.

llt 14

llr 33

lld 15

hlt 33

hlr 33

hld 24

The difference between the 2 pulls was 3 more numbers on the timing and 2 more on the duration. I most certainly can tune the "over 3000rpm" to make more power with just the SSR and pull power out of the lower end.

Did that dyno have a load cell? No way you were only making 1400 ftlbs. See the slope of your torque line when it starts falling.

On the street or track take a straight edge and extend that line up and back towards 2000 rpm.

I wish guys would just phucking quit using horse power as the benchmark for bending rods. Its torque period. 1000HP puller that spins 5K great. Now make 1000HP at 2400 rpm and get back to me after you punch holes in the block. The difference? The torque of course.

Just do the billet rods.

On the gaps, I'd never use gapless rings of any kind on a street truck with factory pistons with the keystone top ring. Just do the OEM Cummins rings.

I've been getting away with 23-25 thou gap on the top ring. Don't think I'd ever go below 20 thou.

Fullboarcummins

Full Boar mobile dyno

- Joined

- Nov 24, 2011

- Messages

- 148

I didn't bring the load cell to that event.

JasonCzerak

Active member

- Joined

- Aug 10, 2006

- Messages

- 14,826

Paul,

with the stock radiator canister i got it down to maybe 2" in the canister to keep coolant from pushing out of the vent tube. The radiator remained full. This is with a wicked bypass kit. it was stable and consistent. if i had the radiator low and the canister empty my electric fan were erratic.

Joe, the load cell was not hooked up. If i were to take my 1/8 of 7.1, push it to 7.0 considering i ran out of fuel before the 1/8, convert to 1/4 mile at 7015# that's 860whp. considering the fueling issues at the track and not an accurate 1/8et that dyno pull would be rather accurate for HP.

I'll get on that same dyno with the load cell this fall i hope.

Notes taken on the ring specs. Thank you

with the stock radiator canister i got it down to maybe 2" in the canister to keep coolant from pushing out of the vent tube. The radiator remained full. This is with a wicked bypass kit. it was stable and consistent. if i had the radiator low and the canister empty my electric fan were erratic.

Joe, the load cell was not hooked up. If i were to take my 1/8 of 7.1, push it to 7.0 considering i ran out of fuel before the 1/8, convert to 1/4 mile at 7015# that's 860whp. considering the fueling issues at the track and not an accurate 1/8et that dyno pull would be rather accurate for HP.

I'll get on that same dyno with the load cell this fall i hope.

Notes taken on the ring specs. Thank you

Joesixpack

Pull'n it.

- Joined

- Apr 4, 2008

- Messages

- 4,118

Didn't say anything was wrong with the peak HP part of the curve. Just the full torque curve isn't there.

JasonCzerak

Active member

- Joined

- Aug 10, 2006

- Messages

- 14,826

Didn't say anything was wrong with the peak HP part of the curve. Just the full torque curve isn't there.

I honestly think i have just that little amount of fuel on the low end. That torque curve is just way to flat and smooth. Driving it on the road it feels sluggish (but clean) till the upper rpms.

That was one of the goals, clean and easy to drive until near 2800 rpm.

I'm sure ill get back on that dyno with the load cell this fall yet.

Joesixpack

Pull'n it.

- Joined

- Apr 4, 2008

- Messages

- 4,118

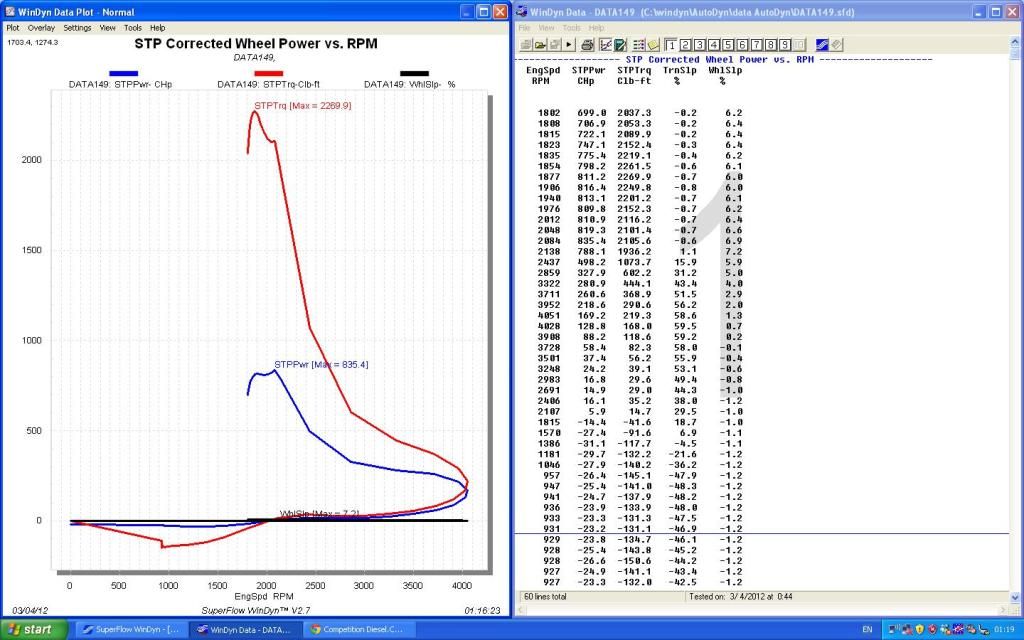

Seems to me your chargers are similar to my old set but billet wheels so should out perform.

For reference:

That was the single pull on the AKA Transmission killer/Rod oh mush tune. Only a measly 835hp LOL but at 2000rpm.

Point being those chargers will compound like mad down low. I'd be very comfortable with the decision to go billet rods.

For reference:

That was the single pull on the AKA Transmission killer/Rod oh mush tune. Only a measly 835hp LOL but at 2000rpm.

Point being those chargers will compound like mad down low. I'd be very comfortable with the decision to go billet rods.

JasonCzerak

Active member

- Joined

- Aug 10, 2006

- Messages

- 14,826

I'd like to debate the dyno here a little.

Note the red line in my graphs. If just a slight tune change took that flat torque line and bumped it up, even way over at 3000rpm. Would that validate point that I'm really only making 1400#foot at 2000? Load cell or not?

If the optimum torque curve is to peak then fall and HP calculated to be flat, thus a huge power under the curve over a very wide RPM range. My outcome is the exact opposite, thus limited by the tune

For debate sake. First pull (motor 50 miles old). Same dyno with the load stuff hooked up. Pull done in 1:1 (vs OD for the 900 one)

SSR 1.5 (the 900whp was SSR 1.7, different stuff)

Torque peeked and HP flattended..... This pull started and ended very fast.

Note the red line in my graphs. If just a slight tune change took that flat torque line and bumped it up, even way over at 3000rpm. Would that validate point that I'm really only making 1400#foot at 2000? Load cell or not?

If the optimum torque curve is to peak then fall and HP calculated to be flat, thus a huge power under the curve over a very wide RPM range. My outcome is the exact opposite, thus limited by the tune

For debate sake. First pull (motor 50 miles old). Same dyno with the load stuff hooked up. Pull done in 1:1 (vs OD for the 900 one)

SSR 1.5 (the 900whp was SSR 1.7, different stuff)

Torque peeked and HP flattended..... This pull started and ended very fast.

Last edited:

Joesixpack

Pull'n it.

- Joined

- Apr 4, 2008

- Messages

- 4,118

This is just dyno 101. Inertia only unless its a very large heavy roll and tall gears to boot is not very effective at showing low rpm torque.

This graph above is good data from 3100 and up. Get on a Superflow and do timed sweeps, 8 seconds like the bull riders. (That 8 seconds seems like forever when you are really putting the screws to it.) The Superflow let's you pick the start and end mph and then you go up against your start point and you can go WOT and stabilize at full boost for the rpm and then hit the accel button and the sweep begins. THEN you see your real torque.

This graph above is good data from 3100 and up. Get on a Superflow and do timed sweeps, 8 seconds like the bull riders. (That 8 seconds seems like forever when you are really putting the screws to it.) The Superflow let's you pick the start and end mph and then you go up against your start point and you can go WOT and stabilize at full boost for the rpm and then hit the accel button and the sweep begins. THEN you see your real torque.

JasonCzerak

Active member

- Joined

- Aug 10, 2006

- Messages

- 14,826

Yeah..... one of these days

ctdiesel99

Comp Diesel Sponsor

- Joined

- Nov 23, 2008

- Messages

- 2,789

Your rods were delivered at 9:48 this morning.

This thing running yet?? LOL

This thing running yet?? LOL

JasonCzerak

Active member

- Joined

- Aug 10, 2006

- Messages

- 14,826

w00t!

JasonCzerak

Active member

- Joined

- Aug 10, 2006

- Messages

- 14,826

Machining juices hate paint...

New paint!

Getting there. unfortunately I'm going to be out of town for a while. So this is chris' new parts truck

New paint!

Getting there. unfortunately I'm going to be out of town for a while. So this is chris' new parts truck

Last edited:

12vriviera

That Guy with that car

- Joined

- Mar 31, 2009

- Messages

- 6,846

Ahhh that's your truck engine he is plastering all over Facebook!

Its almost completely assembled now.

Its almost completely assembled now.

JasonCzerak

Active member

- Joined

- Aug 10, 2006

- Messages

- 14,826

Was hoping to have gotten it yesterday but some parts didn't arrive in time. Work/Vacation coming up in a week I won't be able to pick it up for a few weeks.

CSnyder

Snyder-Motorsports

- Joined

- Mar 3, 2008

- Messages

- 6,278

Machining juices hate paint...

New paint!

Getting there. unfortunately I'm going to be out of town for a while. So this is chris' new parts truck

Dukes of Hazzard style down the dirt roads!

Snedge

Comp Diesel Sponsor

- Joined

- Sep 1, 2006

- Messages

- 18,886