paulb

New member

- Joined

- Jul 14, 2006

- Messages

- 1,673

Thanks for sharing! Now that you show it, it makes sense, but I would not have guessed it.

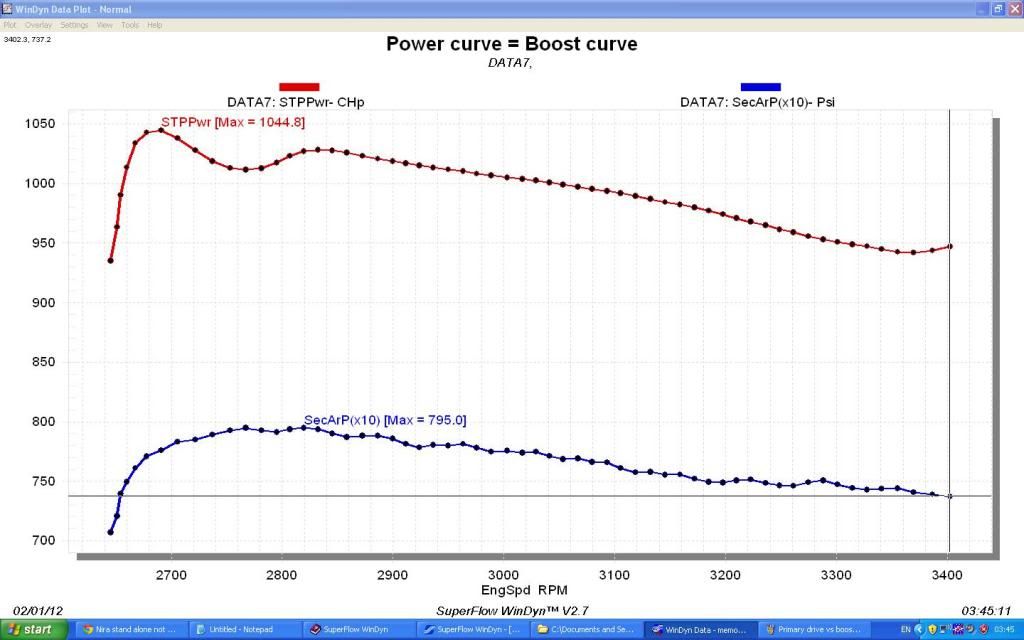

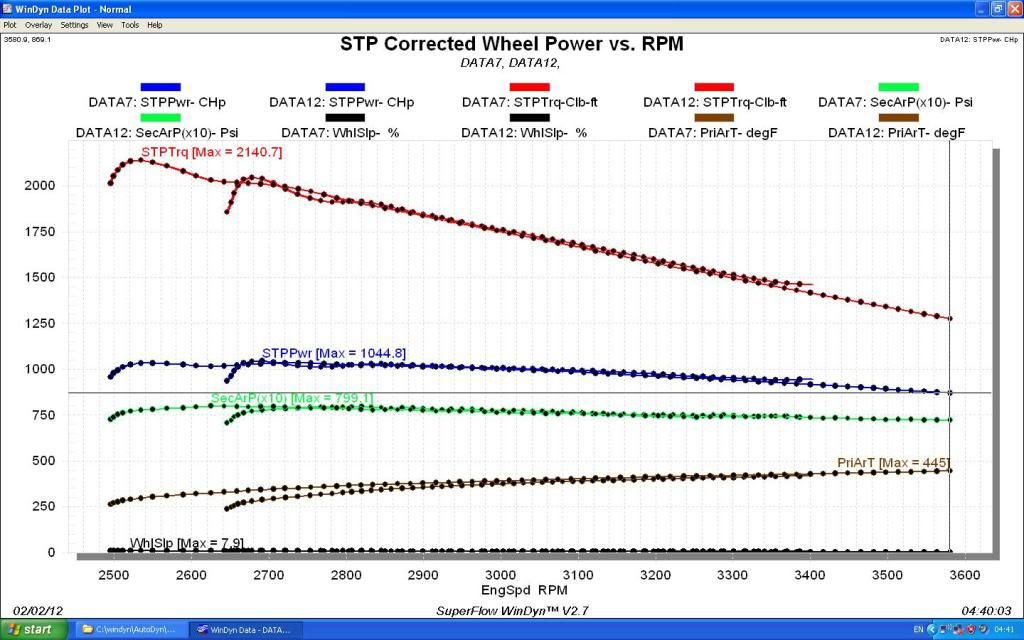

A 1044hp at 79.5 psi (at the secondary). Very close to mine. I made 1040hp, with 82psi (at the manifold).

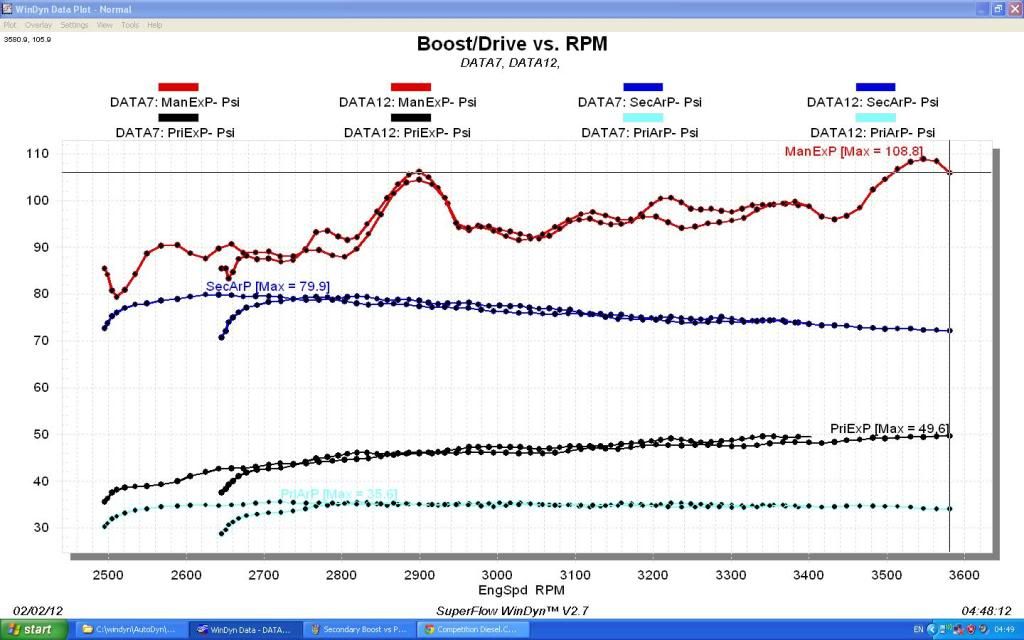

Hp and boost were "following" each other. By the opacity test, I'm guessing that fueling wasn't dropping off, so the limit factor was air? Or was it because the drive pressure keep climbing even though the boost was dropping, and the increased drive pressure was reducing hp? I wonder what would happen if you wastegated the primary.

Thanks again...

Paul

A 1044hp at 79.5 psi (at the secondary). Very close to mine. I made 1040hp, with 82psi (at the manifold).

Hp and boost were "following" each other. By the opacity test, I'm guessing that fueling wasn't dropping off, so the limit factor was air? Or was it because the drive pressure keep climbing even though the boost was dropping, and the increased drive pressure was reducing hp? I wonder what would happen if you wastegated the primary.

Thanks again...

Paul