Bodacious

Comp Diesel Sponsor

- Joined

- Jul 8, 2013

- Messages

- 2,177

Thanks 95cummins5.9... seems to narrow the results.

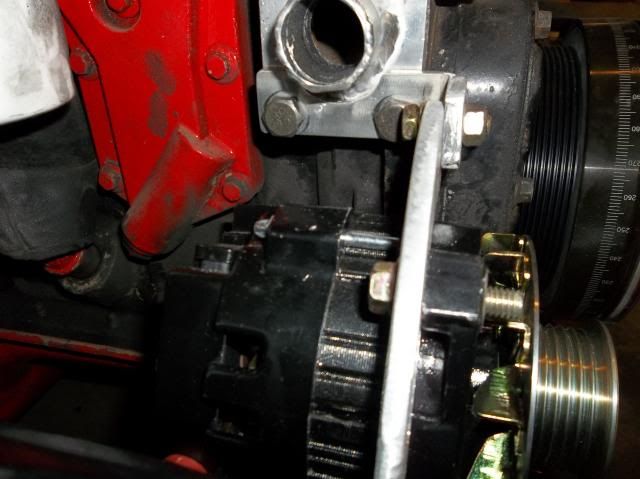

I have been thinking about the crankcase ventilation. After searching, I didn't see anything on here compared to what I've seen on some pro street trucks. I noticed while at Schieds, on some pro street trucks, several places on the engine were vented to a catch can.

Is this particular arrangement required by certain tracks or sanctioning bodies, etc...??

I realize that very high boost pressures could result in oil on the track from the crankcase. So, at the very least, I would want this for safety.

Would it be acceptable to run the crankcase vent to the exhaust, as I've seen posted on here, and forgo the catch can? With the amount of heavy particulates leaving the stack anyway, a little crankcase misting surely wouldn't hurt??

Also, I have personally seen several variations of venting on pulling trucks. Some trucks might have three, another truck might have ten points (no kidding) of venting places. Is there a general rule or should I go for 11? LOL

I have been thinking about the crankcase ventilation. After searching, I didn't see anything on here compared to what I've seen on some pro street trucks. I noticed while at Schieds, on some pro street trucks, several places on the engine were vented to a catch can.

Is this particular arrangement required by certain tracks or sanctioning bodies, etc...??

I realize that very high boost pressures could result in oil on the track from the crankcase. So, at the very least, I would want this for safety.

Would it be acceptable to run the crankcase vent to the exhaust, as I've seen posted on here, and forgo the catch can? With the amount of heavy particulates leaving the stack anyway, a little crankcase misting surely wouldn't hurt??

Also, I have personally seen several variations of venting on pulling trucks. Some trucks might have three, another truck might have ten points (no kidding) of venting places. Is there a general rule or should I go for 11? LOL