You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

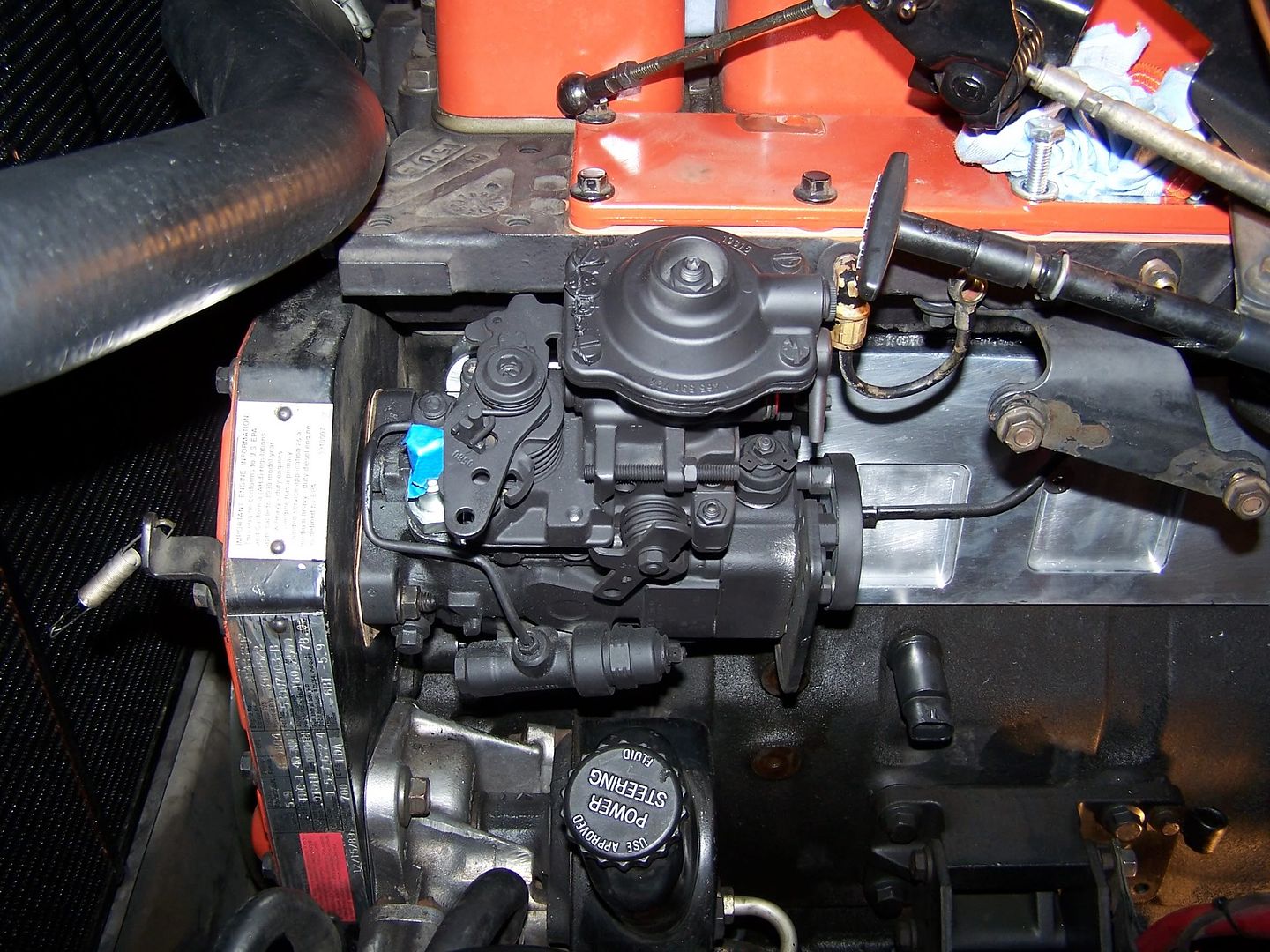

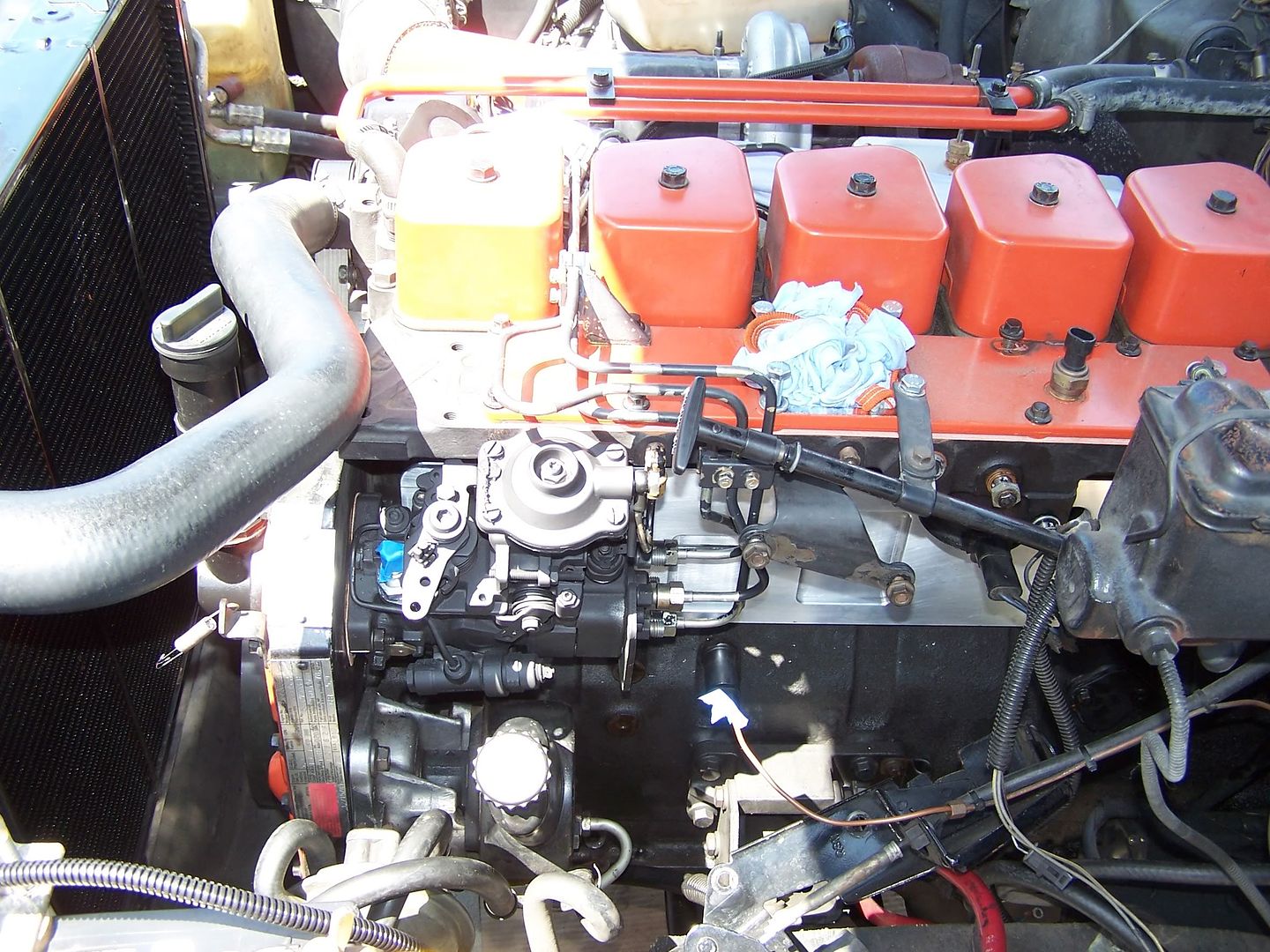

Custom 12mm VE coming soon!

- Thread starter jimbo486

- Start date

Sutter1stgen

Short for my weight

- Joined

- Apr 9, 2012

- Messages

- 845

Awesome man!! Can't wait to hear how she runs.

ENafziger

New member

- Joined

- Oct 22, 2008

- Messages

- 843

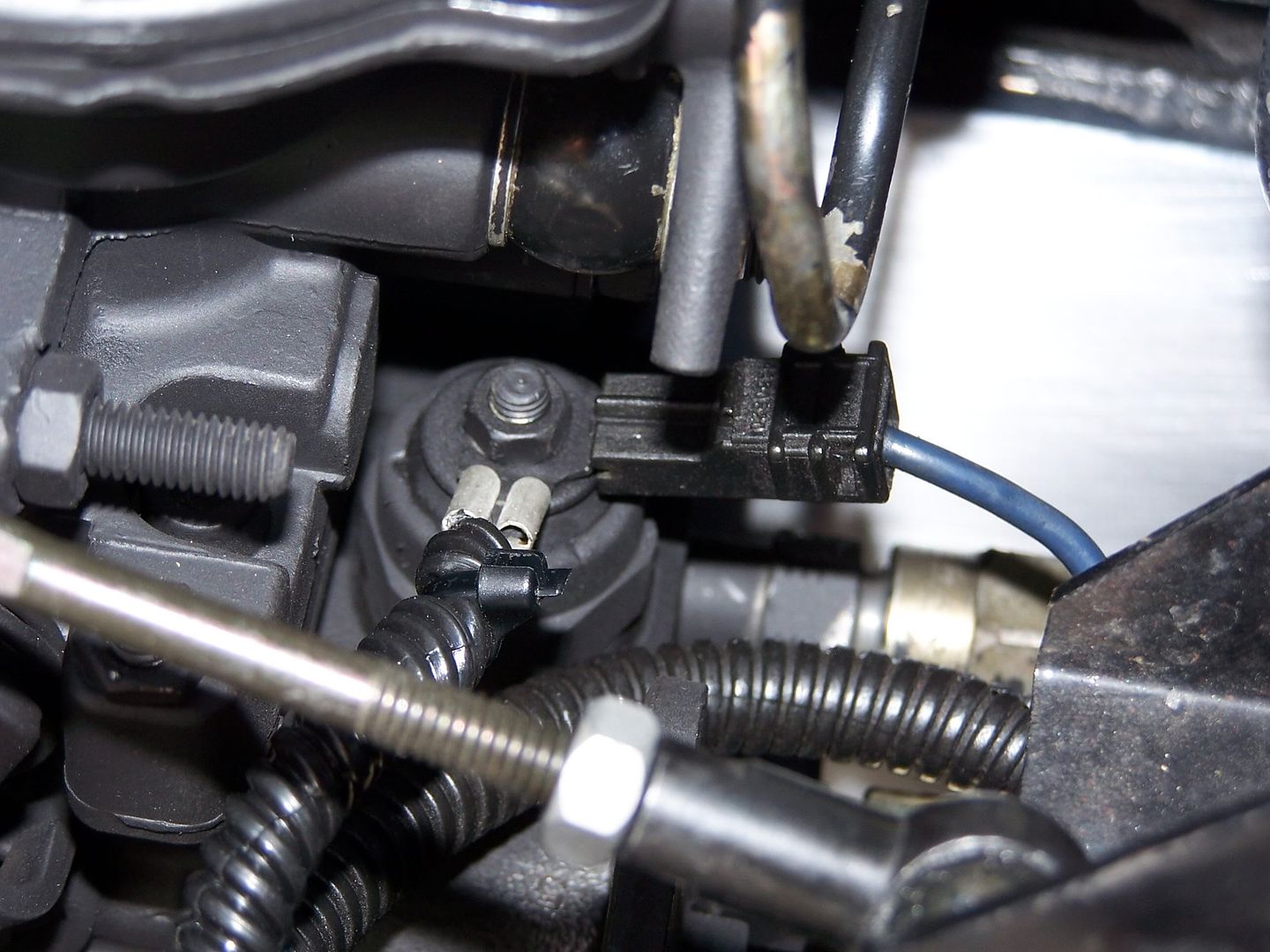

I'm sure you've checked this, but does the nut on the bottom of your throttle arm hit the top of the fuel line where it goes into the pump? Reason I ask, is I have basically the same setup as you do, and I couldn't move my throttle arm to the inner hole without having clearance issues.

Install is looking great!!!

--Eric

Install is looking great!!!

--Eric

Bponci

rookie

- Joined

- Sep 15, 2006

- Messages

- 2,160

Let me shed a little light on this subject. I run a Bradley's built injection pump with a KTA head and rotor. Ponci did help out with the fitting for the duel feed, but he tends to let Carl Bradley and I mess with the pump. Anything else and he is game.

Stomp

Interesting............

jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

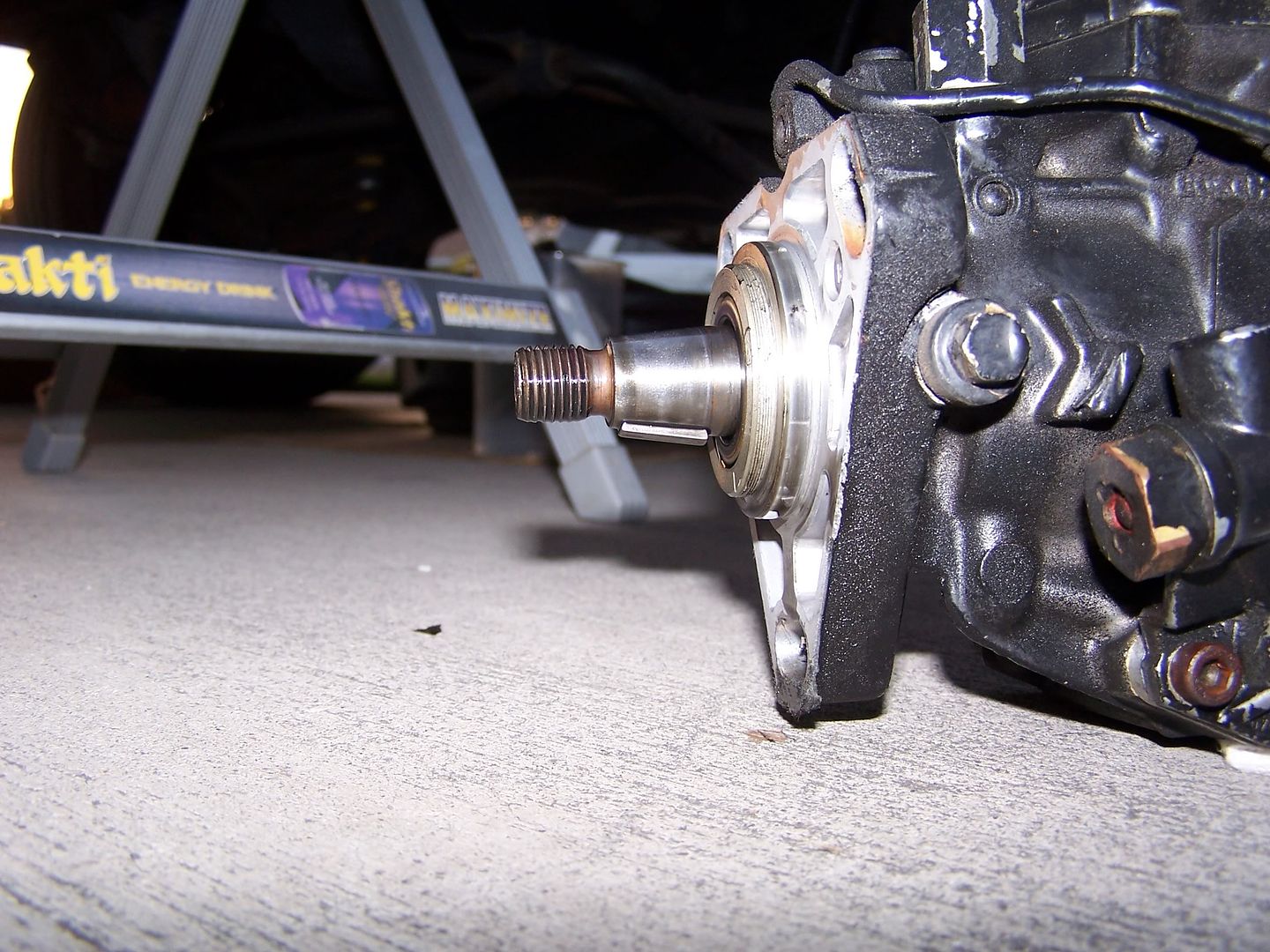

Skipped a tooth and to the head? Or just to the head?

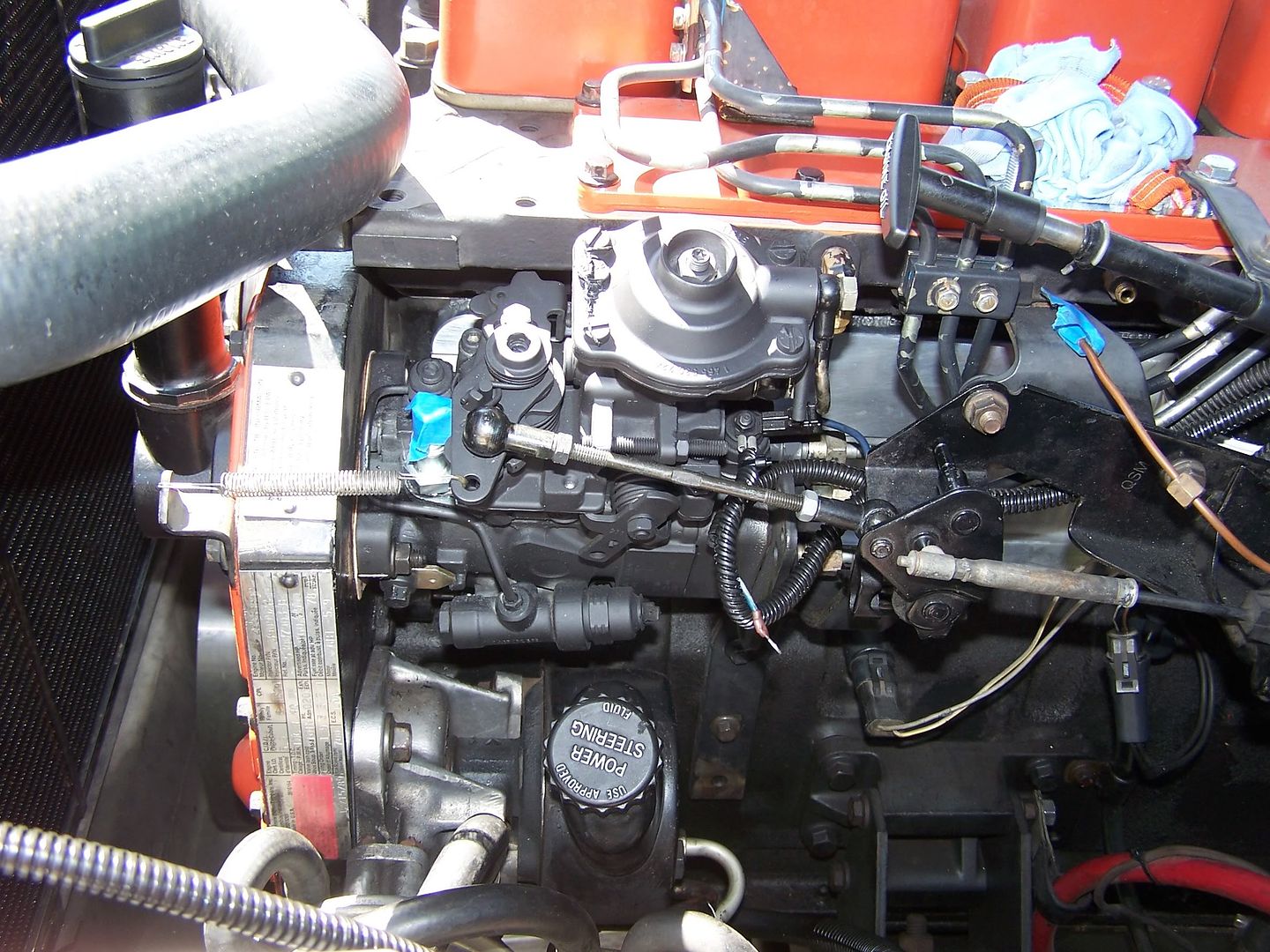

That's where it wound up. Engine and pump were both locked at TDC #1. Everything lined up without any adjustments needed. Giles did tell me the static timing was set to the upper end of its range, 1.3mm. That could be why it's where it is.

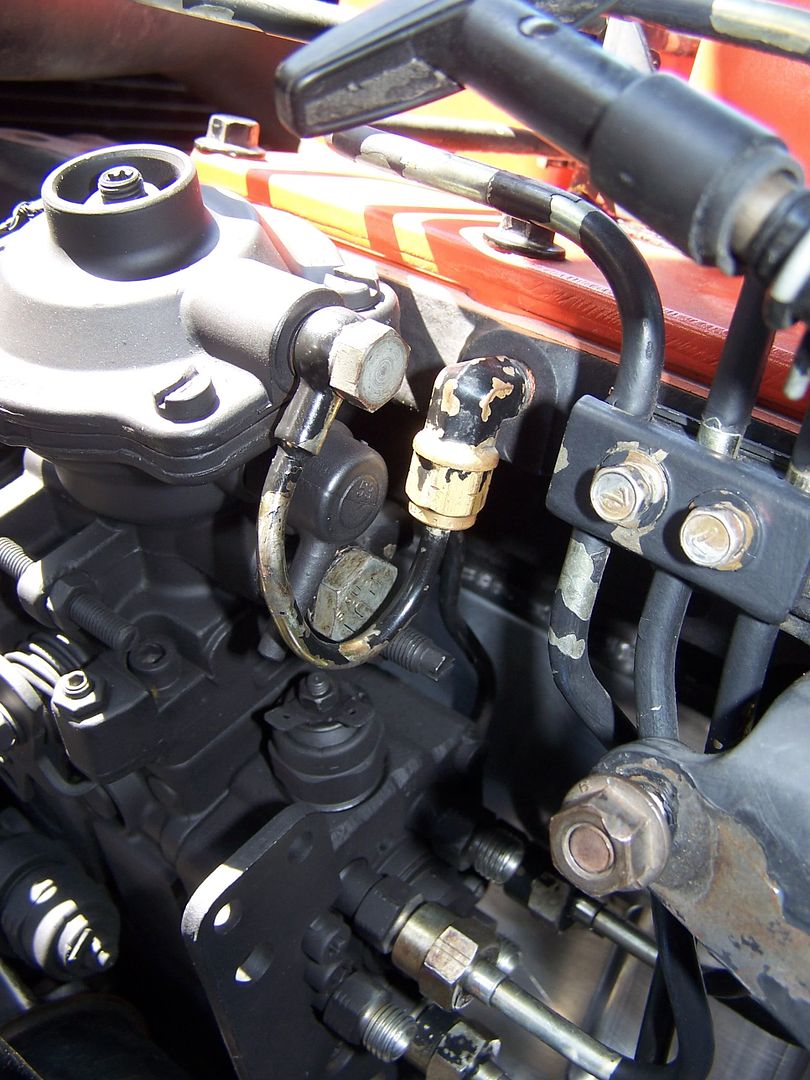

I'm sure you've checked this, but does the nut on the bottom of your throttle arm hit the top of the fuel line where it goes into the pump? Reason I ask, is I have basically the same setup as you do, and I couldn't move my throttle arm to the inner hole without having clearance issues.

Install is looking great!!!

--Eric

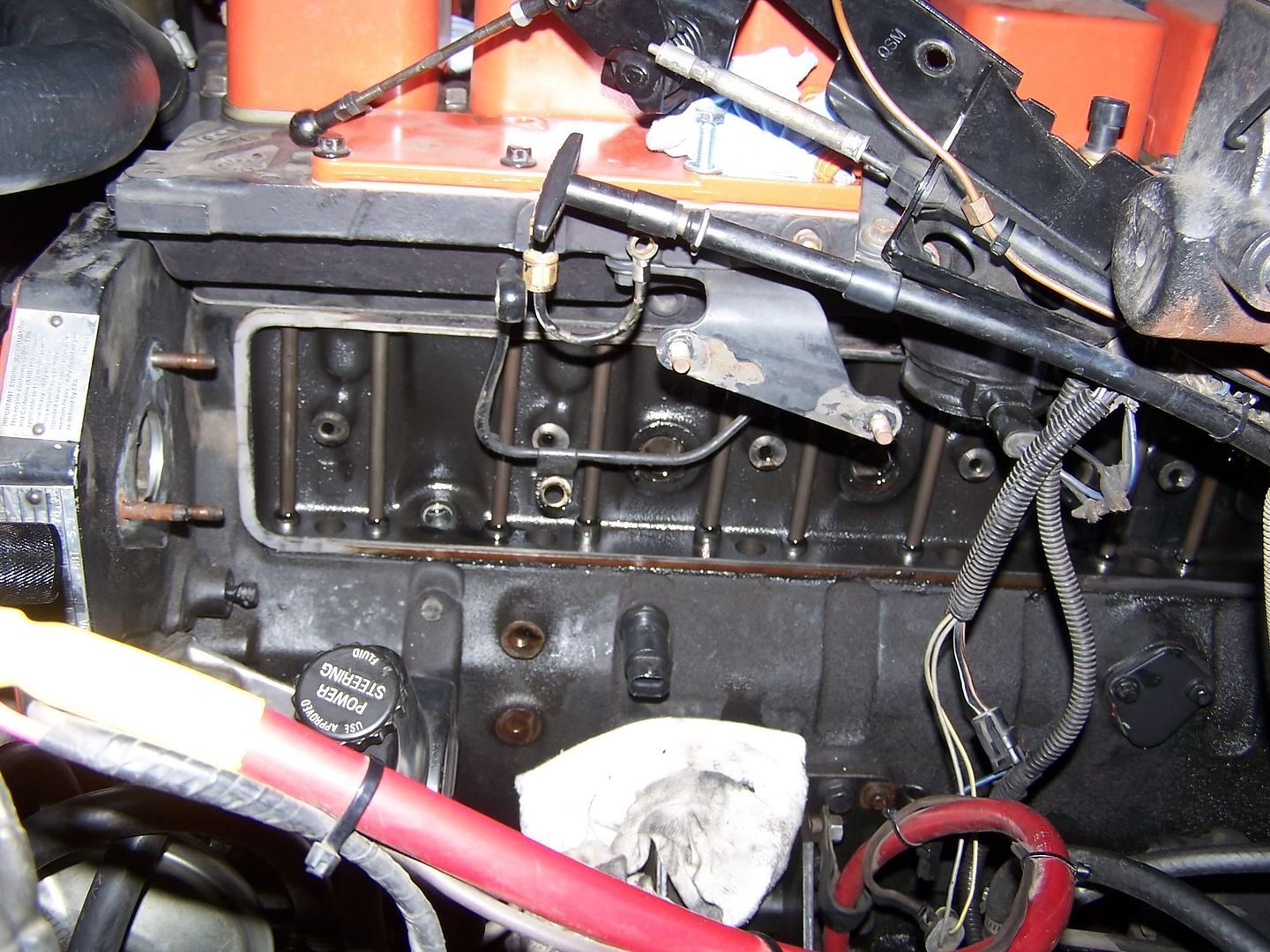

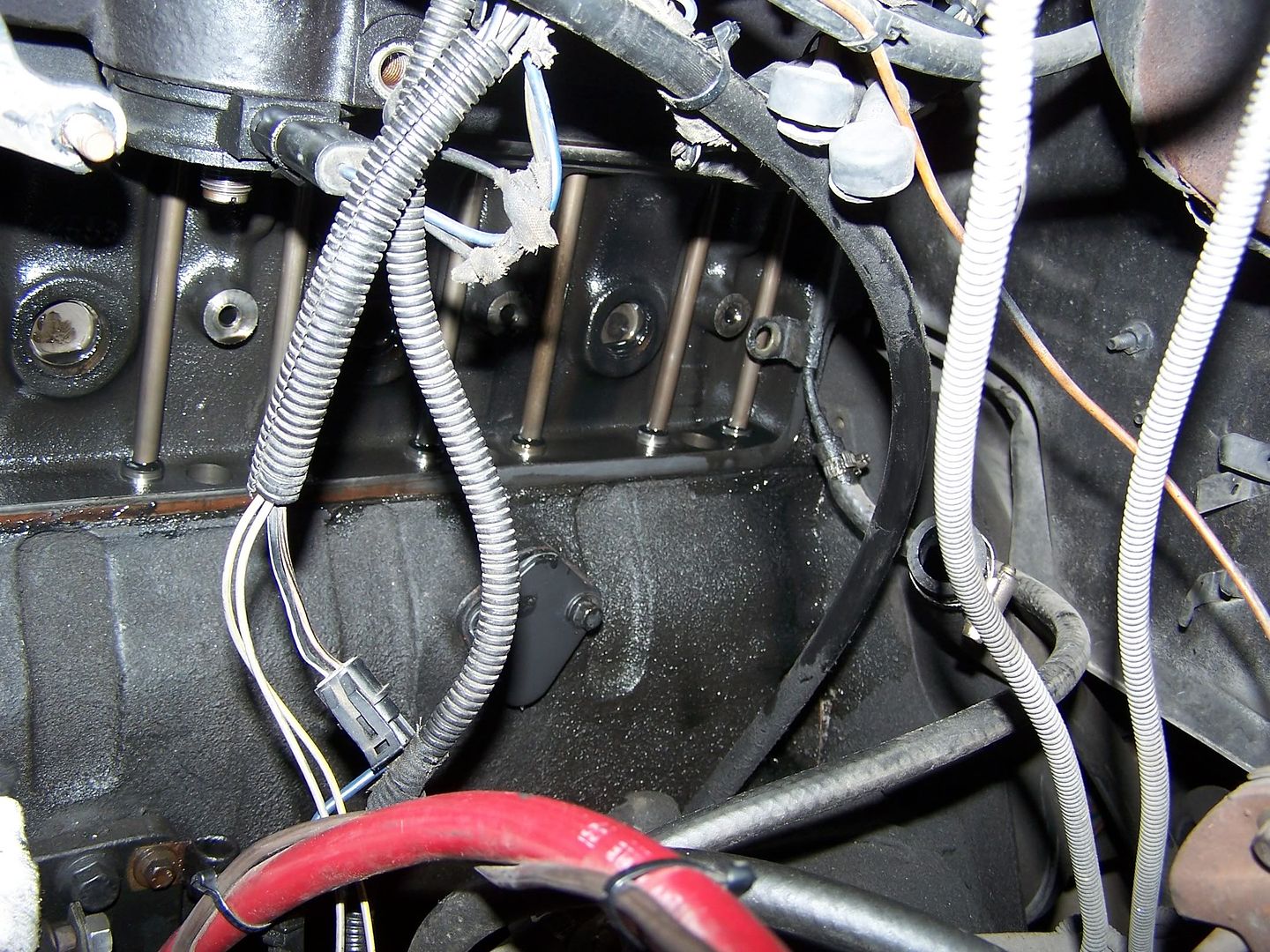

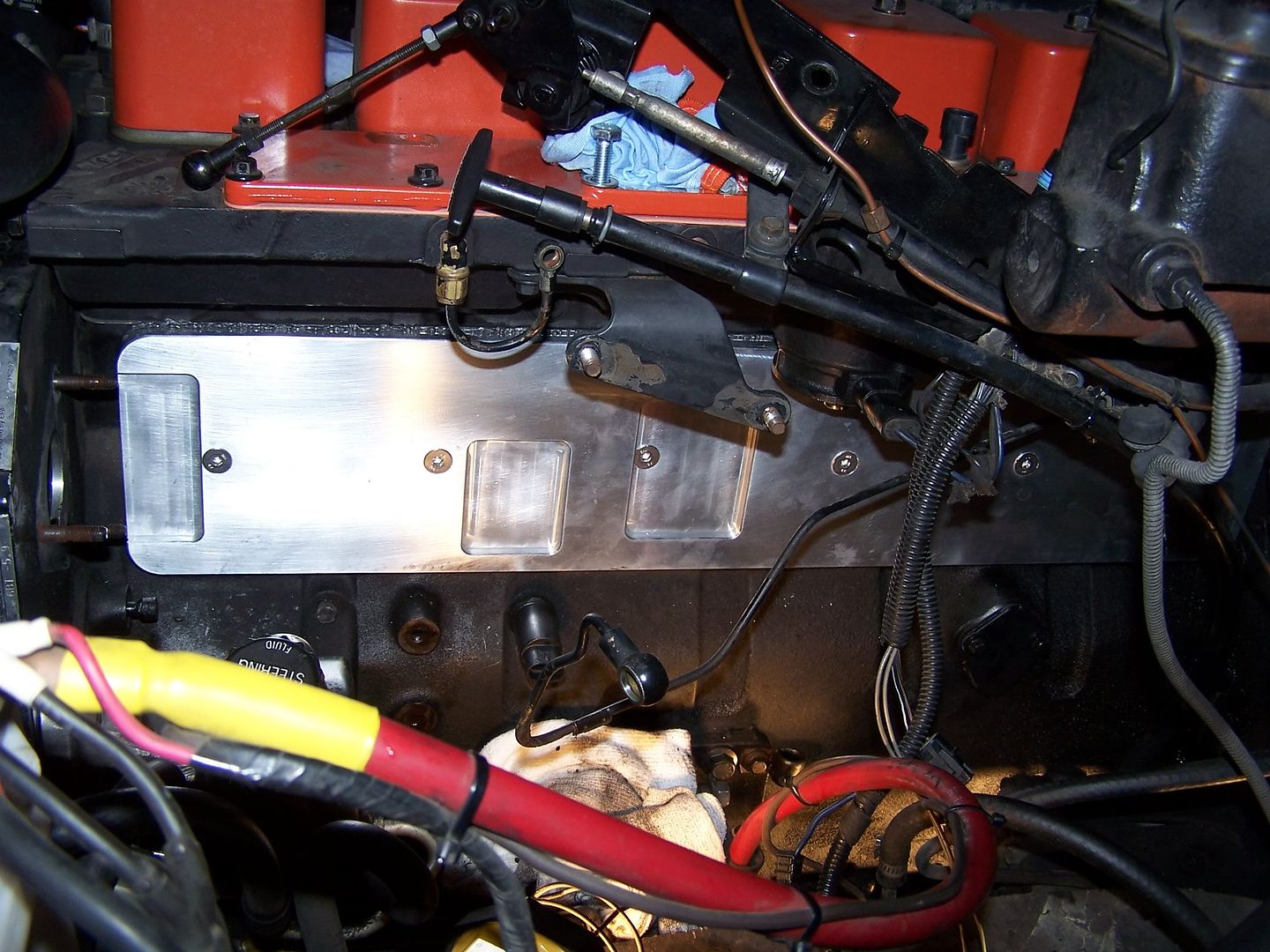

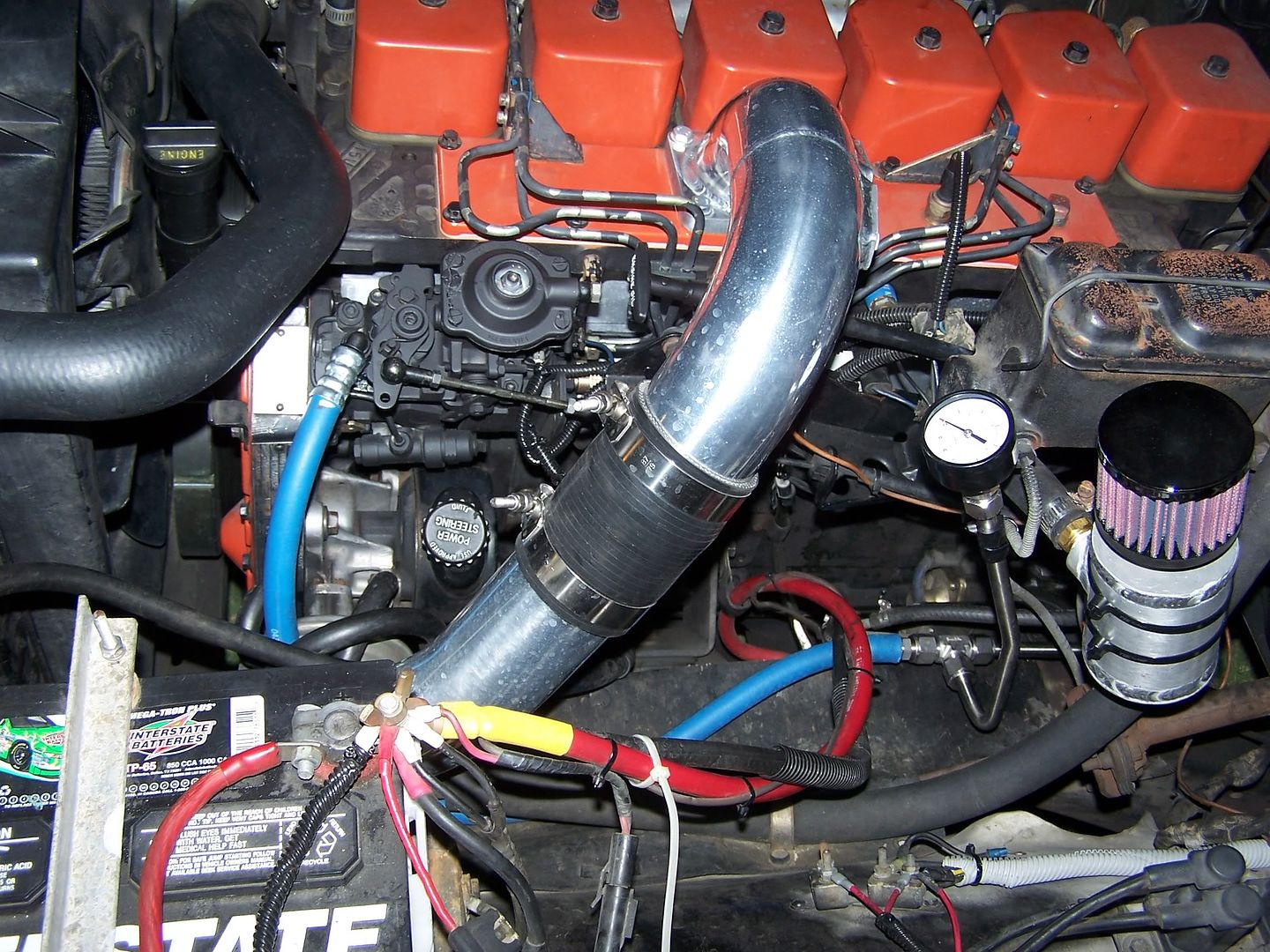

Thank,s Eric! I worked my ass off this weekend! I don't have the same interference as you. Where I have the fuel line clocked is where it clears everything. The throttle lever can return to idle and I can reach full fuel without any interference. The little return spring was touching the fuel line, so I ditched it since it's not really necessary. I think it was you that brought that to my attention.

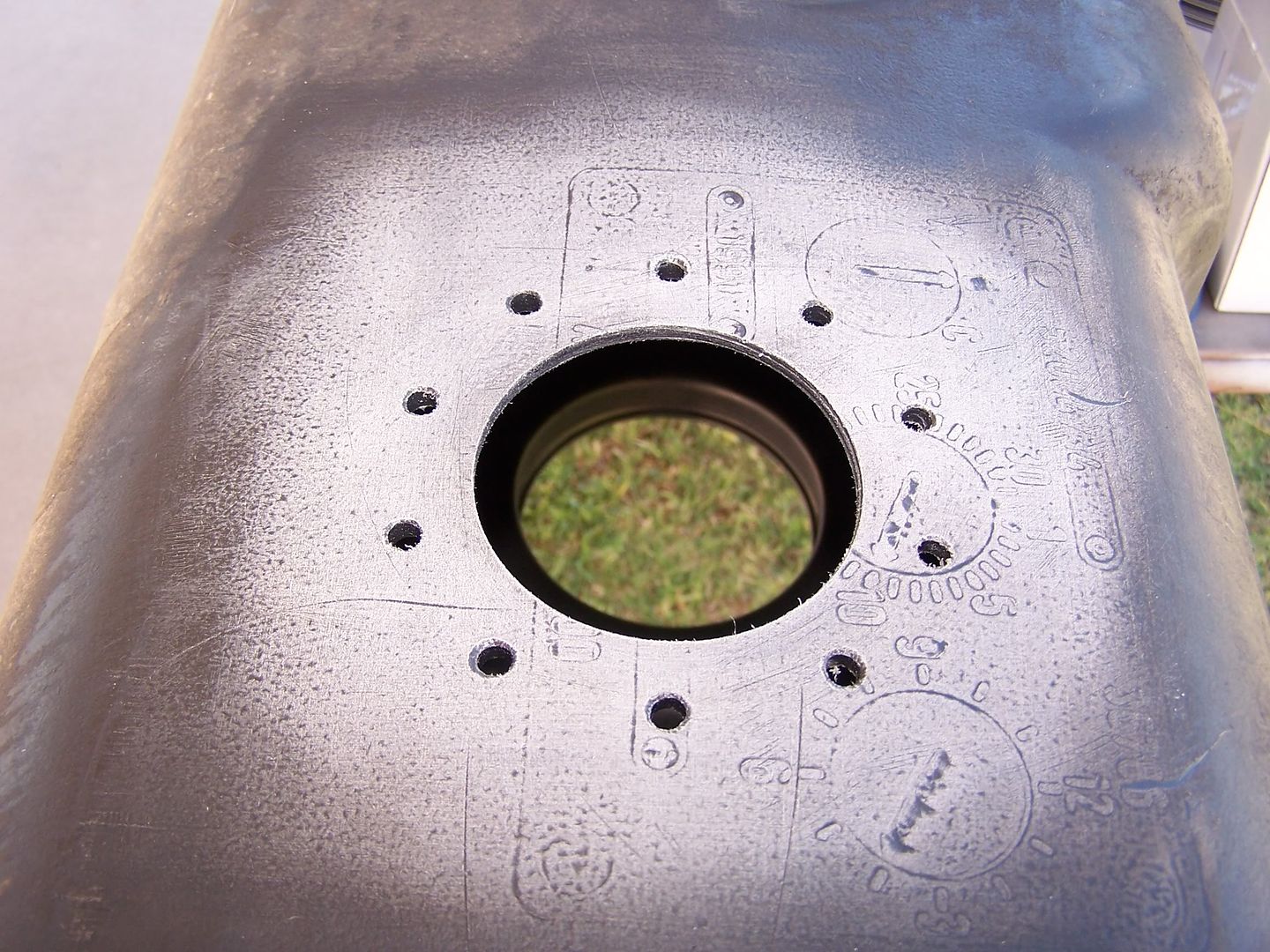

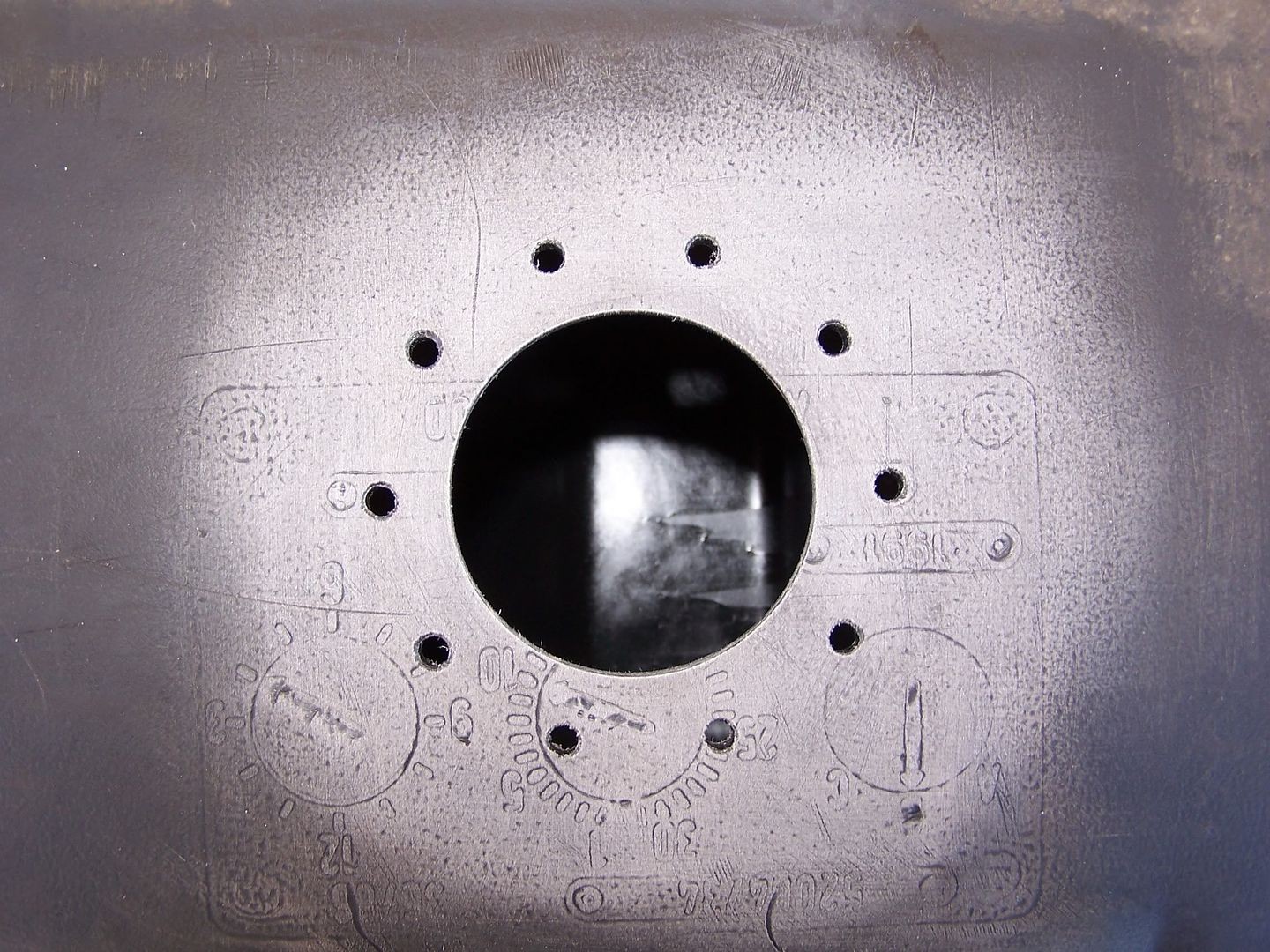

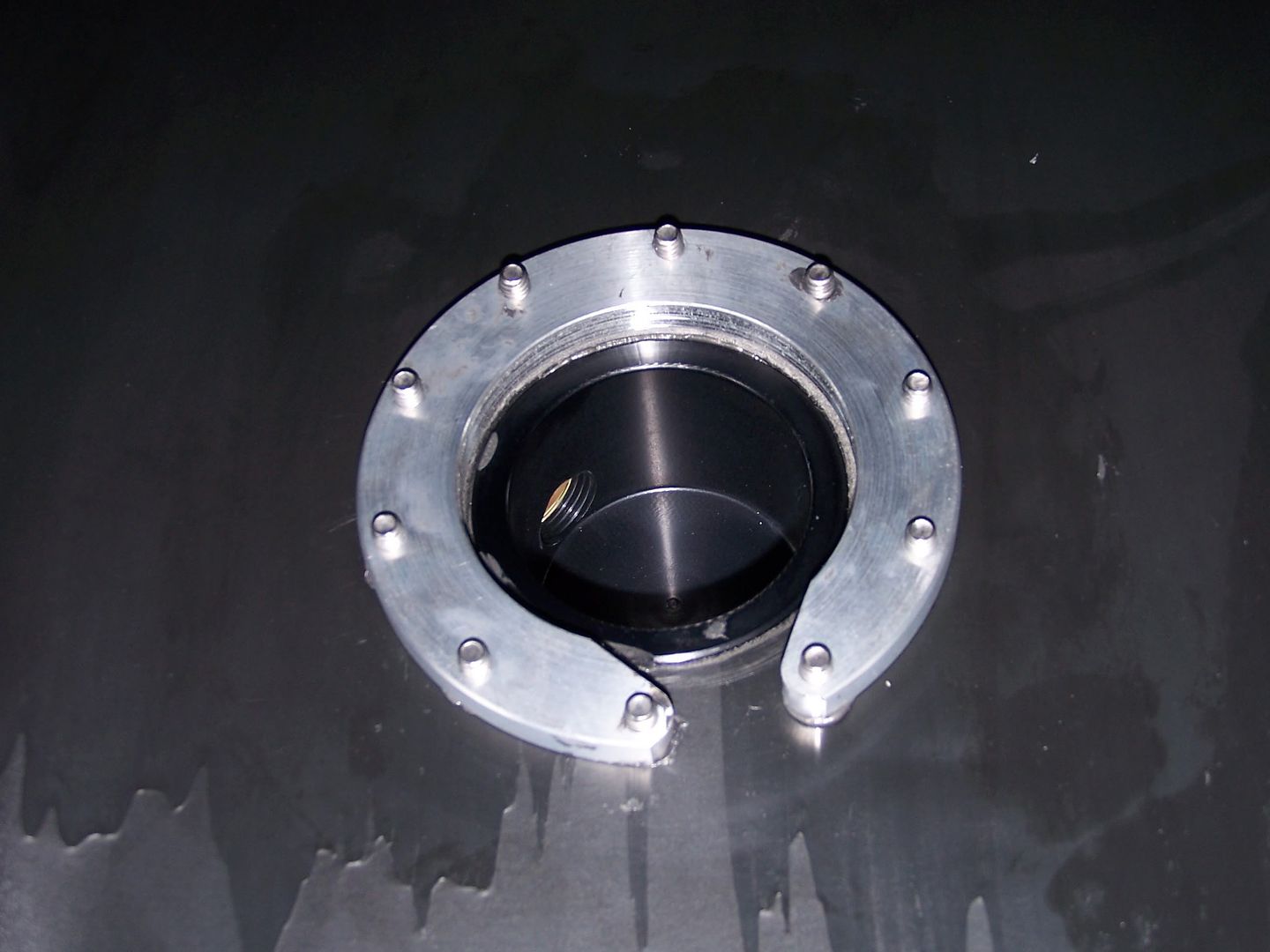

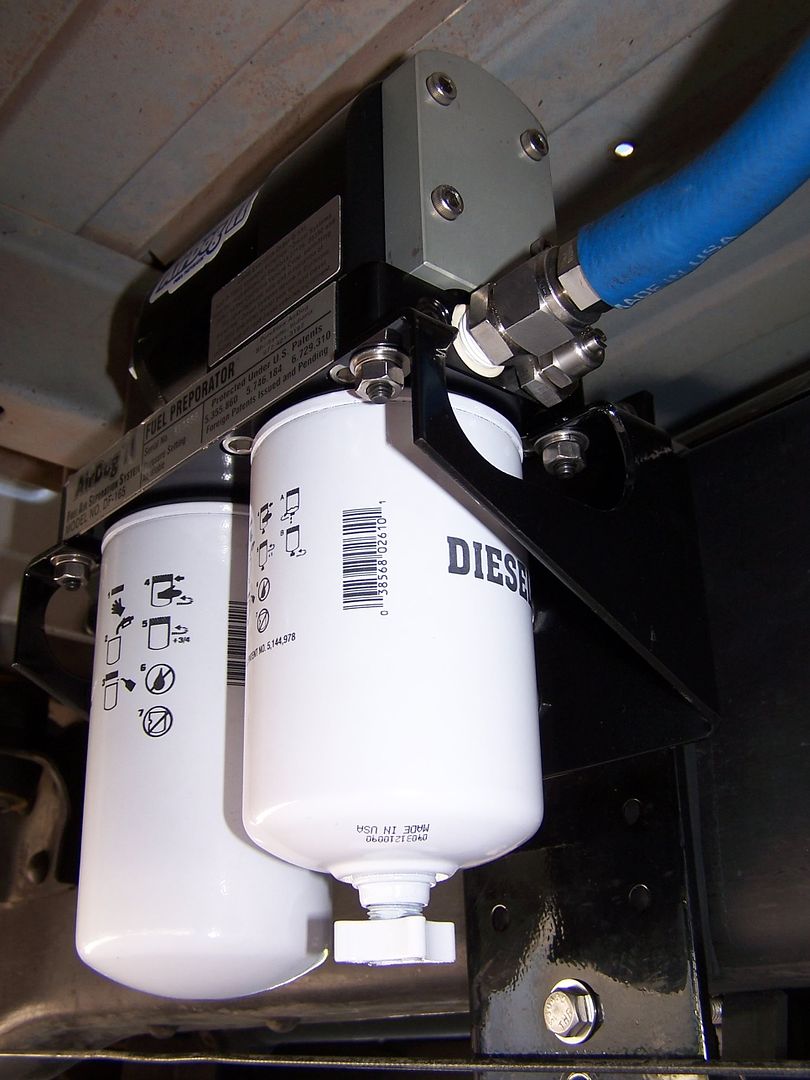

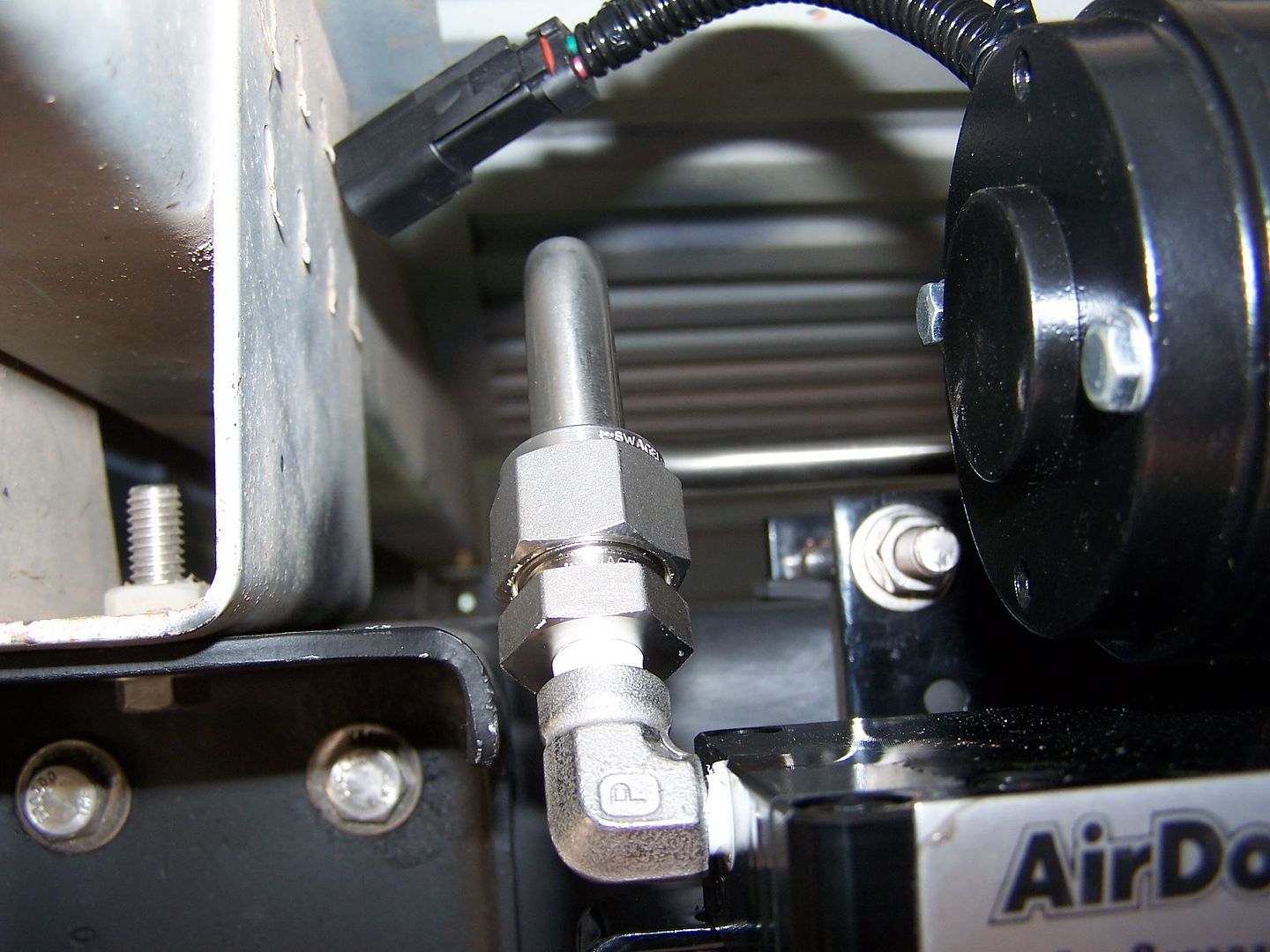

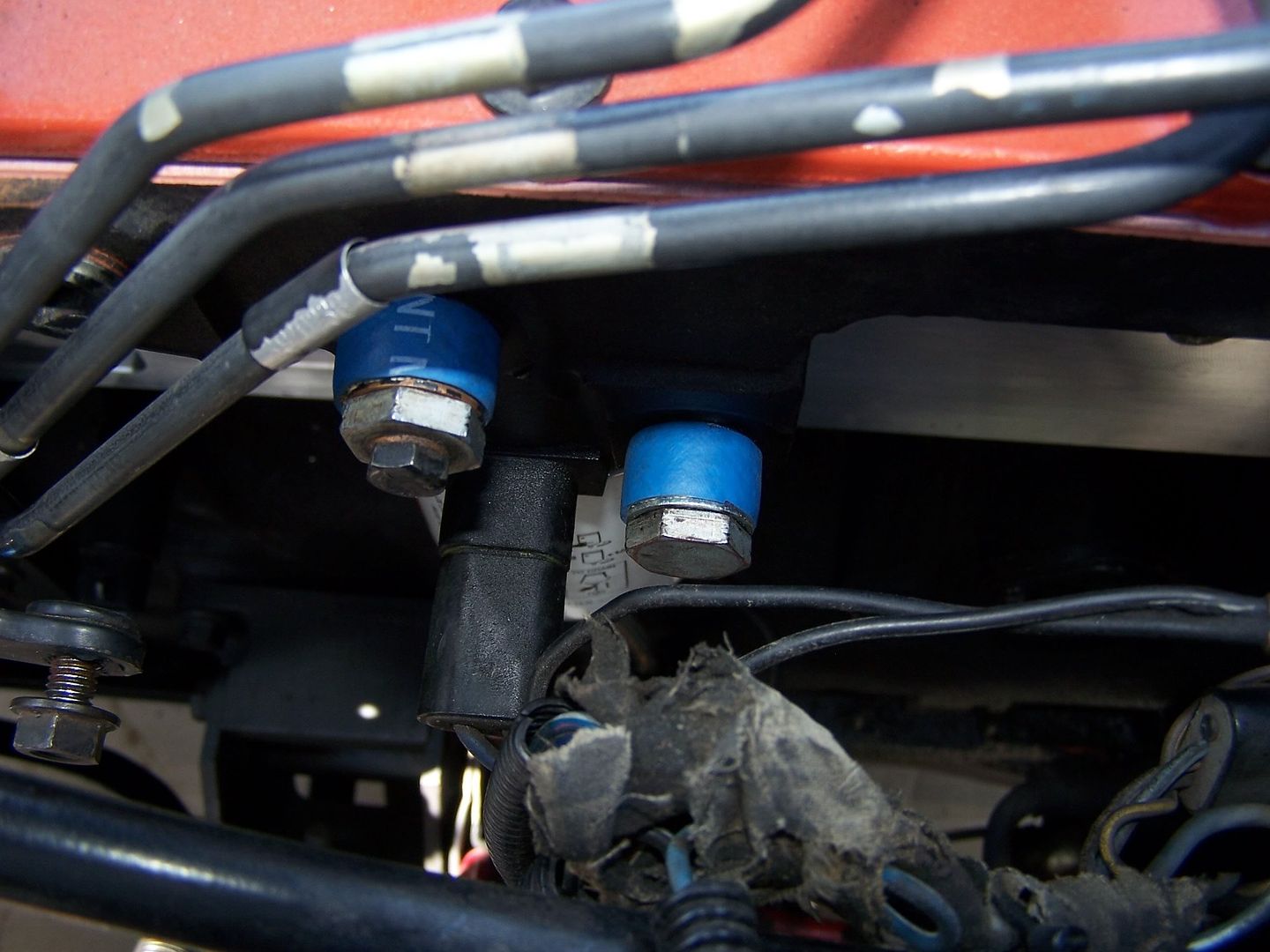

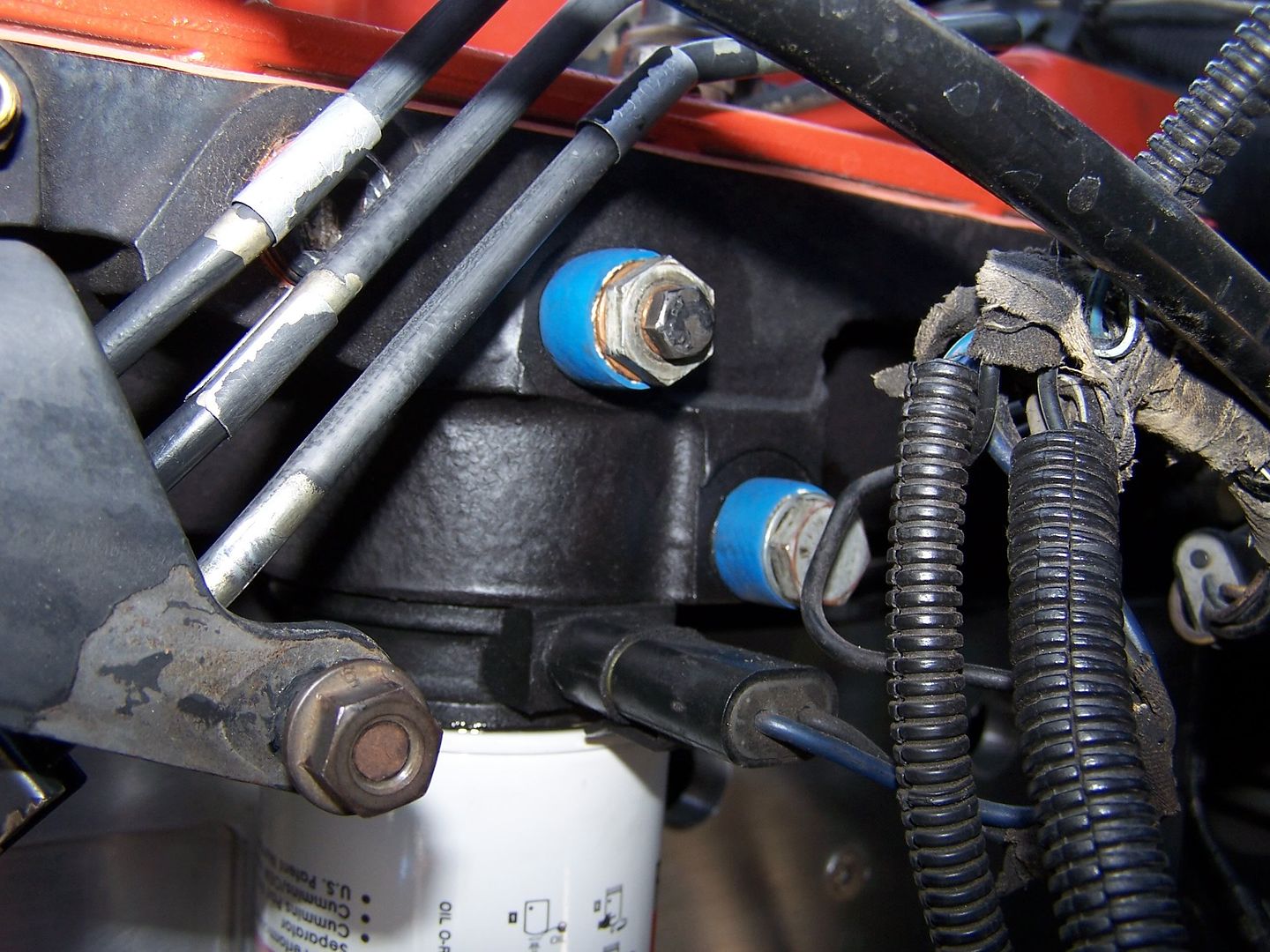

However, what I did run into with the M12 x 1.5 fitting from Airdog is that the hex is too large. I had to grind some of the pump housing just above the sealing surface for the fitting and seal to seat fully. Just as well, the 90deg. quick connect hose-end diameter is a little too large. Luckily, it pressed in place without giving much of a fight. No leaks though! :rockwoot:

Last edited:

rednsilver90

1stgen Fan

- Joined

- Nov 8, 2008

- Messages

- 83

How does it run?

jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

It runs much better than my original pump! Very little applied throttle gets it moving pretty well. I hardly notice any smoke unless I've got my foot in it. Everyday, around town driving yields hardly any, even in each gear. I'll find out tomorrow morning just what it's putting out with my other supporting mods.

rednsilver90

1stgen Fan

- Joined

- Nov 8, 2008

- Messages

- 83

Sweet!

BC847

Member

- Joined

- May 14, 2006

- Messages

- 851

Sooo .. . . . . what's you point?Just p pumped our pullin truck way better than any ve

fire power

slop burner

- Joined

- Mar 13, 2009

- Messages

- 1,130

Just p pumped our pullin truck way better than any ve

how special!!

JBradley500

New member

- Joined

- Jan 21, 2010

- Messages

- 222

Just p pumped our pullin truck way better than any ve

I don't think that's ever been done before. :bow:

oldestof11

Drag racer

- Joined

- Jul 17, 2007

- Messages

- 9,084

Sooo .. . . . . what's you point?

how special!!

I don't think that's ever been done before. :bow:

We interrupt this programming to bring you this special bulletin!

Now, back to you Jim!

SSpeeDEMONSS

Still Learning

- Joined

- May 11, 2006

- Messages

- 3,370

I heard it put down 249/569.

Garrett

encrypted with an enigma machine

Garrett

encrypted with an enigma machine

oldestof11

Drag racer

- Joined

- Jul 17, 2007

- Messages

- 9,084

That seems way off. Considering he put down more than that 2 years ago...

SSpeeDEMONSS

Still Learning

- Joined

- May 11, 2006

- Messages

- 3,370

I think it's the same dyno.

Garrett

encrypted with an enigma machine

Garrett

encrypted with an enigma machine

JQmile

Comp Diesel Sponsor

- Joined

- Nov 19, 2006

- Messages

- 6,976

Nice meeting you today "Jimbo486"

Needs more cowbell and coal, and I think you'll have it. I appreciate those who can make power with small injectors on a VE, but I never could. Some big sticks and skipping a tooth would probably pick up another 150-200hp. 1,200deg EGT is where you tow at, not dyno at :lolly:

Also have a video I can post if you want.

Jason

Needs more cowbell and coal, and I think you'll have it. I appreciate those who can make power with small injectors on a VE, but I never could. Some big sticks and skipping a tooth would probably pick up another 150-200hp. 1,200deg EGT is where you tow at, not dyno at :lolly:

Also have a video I can post if you want.

Jason