You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

95' Junker Drag Truck

- Thread starter Big Blue24

- Start date

npe3484

I hate ATF

- Joined

- May 10, 2009

- Messages

- 792

I could probably get the truck to run decent if I manually shifted it 1st, 2nd, 3rd, OD. The problem is, I didn't build the low/reverse servo and rear band strong enough to take the abuse and I fear a transmission failure will occur if I try to spool-up and launch in manual low.

Using the column shifter to manually shift doesn't sound fun... or easy!

Are you planning to try your big 0.018 hole injectors next with this turbo?

I could probably get the truck to run decent if I manually shifted it 1st, 2nd, 3rd, OD. The problem is, I didn't build the low/reverse servo and rear band strong enough to take the abuse and I fear a transmission failure will occur if I try to spool-up and launch in manual low.

I'm curious why you would say that? I'd expect that manually selecting 1st gear would be better for the tranny considering that you're applying the low/reverse band vs. relying solely on the sprag to hold all the power.

Lostnwalmart

New member

- Joined

- Jul 19, 2006

- Messages

- 8,970

is the turbo a divided housing? if so it may spool better if you make your adapter divided as well. just a theroy it may work may not

Big Blue24

Comp Diesel Sponsor

- Joined

- Jan 5, 2008

- Messages

- 6,320

How hard is that rubber boot on the intake before the charger? I would be afraid of the turbo sucking it in and restricting flow. A buddy rigged up something similar and it would suck that rubber in and kill the truck.

The rubber boot is pretty hard, it came from Airflo.com, a semi-truck supply store and is intended for use on turbo charged intake systems.

Using the column shifter to manually shift doesn't sound fun... or easy!

Are you planning to try your big 0.018 hole injectors next with this turbo?

Yes, the 5x.018 injectors will be the next addition with this turbo. Drag racing is tomorrow night so some time after, I'll be swapping out the 215 injectors and adding the bigger 5x .018's.

I'm curious why you would say that? I'd expect that manually selecting 1st gear would be better for the tranny considering that you're applying the low/reverse band vs. relying solely on the sprag to hold all the power.

I reused the old worn stock low/reverse servo on my tranny build so It is suspect as far as leakage, getting cocked in the bore, cracking, etc. Also, during my initial test driving, the valve body came loose from the body of the transmission and caused a major loss of line pressure. While trouble shooting the problem, I halfway burned up the low/reverse band. I did properly readjust it, but there was quite a bit of black band dust in the pan when I discovered the loose valvebody and the band was really loose because so much clutch material had been worn off the band, 5-1/2 turns to snug it up as I recall and it was initially set around 2 turns. I'm just scared to lean on it too hard cause I know it's not up to par.

is the turbo a divided housing? if so it may spool better if you make your adapter divided as well. just a theroy it may work may not

Yes, this turbo does have a divided housing. I agree, it probably would spool quicker if I bought a divided T6-T3 adapter.

Last night, during my test runs, the turbo is spooling just a touch better. There was better air last night around 11:30 when I was out testing so not sure if the turbo is just loosening up or if the cooler air made the slight difference in spool up.

I also spent an hour and pulled the adapter apart and there was just one small area with a faint wisp of a soot trail. I welded the two halves of my adapter together so now I know for sure there are no pre-turbo exhaust leaks.

Tonight, time permitting, I'm going to tighten the lash on the exhaust valves to about .015 and check the cold side for boost leaks. I think I might tighten the wastegate rod 2 full turns as well. Right now, peak boost is 36 psi and limited by the wastegated housing. On the bench, the rod started to move at 34 psi so I'm going to tighten it a little and try to get 40+ out of it. It's not a fair comparison to run a large single at 36 psi when I was running the stock turbo in the 40+ range.

Last edited:

Signature600

THA MAN!

- Joined

- Aug 5, 2006

- Messages

- 12,015

I reused the old worn stock low/reverse servo on my tranny build so It is suspect as far as leakage, getting cocked in the bore, cracking, etc. Also, during my initial test driving, the valve body came loose from the body of the transmission and caused a major loss of line pressure. While trouble shooting the problem, I halfway burned up the low/reverse band. I did properly readjust it, but there was quite a bit of black band dust in the pan when I discovered the loose valvebody and the band was really loose because so much clutch material had been worn off the band, 5-1/2 turns to snug it up as I recall and it was initially set around 2 turns. I'm just scared to lean on it too hard cause I know it's not up to par.

Hope you don't rip the sprag out of the case...that is NOT fun!!

Chris

BlackSkyRacing

Living Under a Rock

- Joined

- Mar 22, 2007

- Messages

- 1,394

Hope you don't rip the sprag out of the case...that is NOT fun!!

Chris

My friend did that, you're right, it sucks :bang Luckily the low/reverse band was still intact, so we could limp it home... Case cost us $150 from worldwide :Cheer:

EDIT: I also recall telling him to use manual low to play in the mud... He didn't listen and the broken sprag wasn't far behind my suggestion.

Signature600

THA MAN!

- Joined

- Aug 5, 2006

- Messages

- 12,015

Yeah, mine needed a case, intermediate shaft, a drum, and a few other parts...luckily I had a core to get parts out of.

Chris

Chris

Big Blue24

Comp Diesel Sponsor

- Joined

- Jan 5, 2008

- Messages

- 6,320

So you guys are telling me that when guys bust out 9,10,11,12, or 13 second passes, they are launching in Low and quickly banging the shifter into 2nd, then 3rd, then hitting the O/D on/off button or commanding OD with a toggle switch?

I'm going to try to make at least one pass launching in L just to see if I can get this thing to spool late in 1st gear and stay spooled up for the rest of the run.

I tightened down the valve lash to .015" on the exhaust side and it did seem to help spool up come in about 50 rpm sooner.... barely noticeable and could be 100% unrelated to lash adjustment but rather weather conditions, etc.

I also loosened up the starwheel a little bit and is now adding fuel a little sooner. The only real noticeable difference is thicker smoke pre-spool up, and different exhaust tone/sound around 2000 rpm. It sounds like it's trying to spool-up around 2000 rpm but it doesn't really take off till 2400 rpm. During my first test drive, it didn't take off till 2600 rpm so it has improved a little bit.

Midnight drag racing starts at 9PM tonight, I hope to come back with some useful feedback and hopefully a little more MPH.

I'm going to try to make at least one pass launching in L just to see if I can get this thing to spool late in 1st gear and stay spooled up for the rest of the run.

I tightened down the valve lash to .015" on the exhaust side and it did seem to help spool up come in about 50 rpm sooner.... barely noticeable and could be 100% unrelated to lash adjustment but rather weather conditions, etc.

I also loosened up the starwheel a little bit and is now adding fuel a little sooner. The only real noticeable difference is thicker smoke pre-spool up, and different exhaust tone/sound around 2000 rpm. It sounds like it's trying to spool-up around 2000 rpm but it doesn't really take off till 2400 rpm. During my first test drive, it didn't take off till 2600 rpm so it has improved a little bit.

Midnight drag racing starts at 9PM tonight, I hope to come back with some useful feedback and hopefully a little more MPH.

Big Blue24

Comp Diesel Sponsor

- Joined

- Jan 5, 2008

- Messages

- 6,320

Yes, folks with Manual Valve bodies are....Best of luck on the Trap Speed gain... BTW, how loose is your Torque Converter?

Torque converter is tighter than I thought, it was completely stalling at 1600 to 1650 RPM when I was trying to build boost tonight at the strip.

Looking forward to reading your results in the morning.

It's morning!

First note, spool up is so bad that it is very, very, very, difficult to do a burnout on dry pavement.

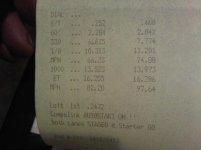

Best pass of the night:

16.28 @ 97.64 MPH.

60' - 2.84

330 - 7.77

1/8 - 11.2 @ 74.88 MPH

1000 - 13.97

ET - 16.286 @ 97.64 MPH.

An interesting note is that on the best 3 passes with stock turbo a few months ago, I averaged 19.6 MPH increase from 1/8 to 1/4 trap speed. Tonight on the other hand, I averaged 24.2 MPH increase from 1/8 to 1/4. Using simple math if my normal 1/8th is 80 MPH, my new trap speed should be 103 to 105 MPH, an increase of 30 to 60 HP.

Long story short, the only way to make the truck run quicker than 17.5 was to start in manual L, shift to 2nd at 3000 rpm, shift to D at 3000 RPM, and Shift to OD at 2900 RPM. Driving this way resulted in slow spool-up in 1st gear and it never fully lit. It would take about 1 full second for the turbo to light in 2nd gear and it would pull hard enough to cause tire shake in second and the RPM would bounce between 3000 and 3500 till it finally hooked good and I shifted to D. Once in 3rd gear, there was zero lag and tons of power, turbo really liked the load and fueling setup in 3rd gear. OD was hit or miss, sometimes it seemed to just half light for a second and other times it seemed to pull just as well as 3rd gear.

On my best time of the night, I was able to get the back tires spinning in the dry water box and then snuff the charger out with the brakes while keeping my foot in the throttle. Then I gently let the truck creep forward and stage. The turbo pitch would change every once in a while like it was about to spool but then it would bog down. Might be a tuning issue, might be just the way the turbo naturally acts as it spools and de spools. My gauge did not register boost on the best pass but it definitely had the most turbo whistle/spool up sound.

Two feet after launching, the truck falls on it's face, almost like the torque converter tightens up a just hair as you let the tranny start moving from a dead stall.

I hot lapped the truck several times at the end of night thinking hotter tranny fluid would loosen the converter a hair, but it didn't seem to make much difference.

Attachments

Signature600

THA MAN!

- Joined

- Aug 5, 2006

- Messages

- 12,015

So you guys are telling me that when guys bust out 9,10,11,12, or 13 second passes, they are launching in Low and quickly banging the shifter into 2nd, then 3rd, then hitting the O/D on/off button or commanding OD with a toggle switch?

Yep, pretty much...although I'd say some are using a lockup and 4th gear control box for those functions...I know I will be.

What charger are you running if you can't light it at the line?

Chris

Limited

Slow N' Quiet

- Joined

- Apr 17, 2008

- Messages

- 2,193

So you guys are telling me that when guys bust out 9,10,11,12, or 13 second passes, they are launching in Low and quickly banging the shifter into 2nd, then 3rd, then hitting the O/D on/off button or commanding OD with a toggle switch?

I'm going to try to make at least one pass launching in L just to see if I can get this thing to spool late in 1st gear and stay spooled up for the rest of the run.

I tightened down the valve lash to .015" on the exhaust side and it did seem to help spool up come in about 50 rpm sooner.... barely noticeable and could be 100% unrelated to lash adjustment but rather weather conditions, etc.

I also loosened up the starwheel a little bit and is now adding fuel a little sooner. The only real noticeable difference is thicker smoke pre-spool up, and different exhaust tone/sound around 2000 rpm. It sounds like it's trying to spool-up around 2000 rpm but it doesn't really take off till 2400 rpm. During my first test drive, it didn't take off till 2600 rpm so it has improved a little bit.

Midnight drag racing starts at 9PM tonight, I hope to come back with some useful feedback and hopefully a little more MPH.

I only run high 12's, but I just put it in OD, spool up and go. Transmission takes care of the rest.

Big Blue24

Comp Diesel Sponsor

- Joined

- Jan 5, 2008

- Messages

- 6,320

Yep, pretty much...although I'd say some are using a lockup and 4th gear control box for those functions...I know I will be.

What charger are you running if you can't light it at the line?

Chris

Next turbo setup is likely going to be my original end goal setup of He351(60mm) over HT4B(83mm).

I'm not giving up on this GT4294 just yet, I'm going to play around with tuning and do a little bit of porting to see if I can get it to spool better. I'm also thinking about dumping my tractor fluid based transmission fluid and going to something a little thinner like straight Type F or Dexron.

Signature600

THA MAN!

- Joined

- Aug 5, 2006

- Messages

- 12,015

With a converter that tight, and a GT4294, you need an .050 hit of juice to light it at the line

Been there!

Chris

Been there!

Chris

Big Blue24

Comp Diesel Sponsor

- Joined

- Jan 5, 2008

- Messages

- 6,320