Big Blue24

Comp Diesel Sponsor

- Joined

- Jan 5, 2008

- Messages

- 6,320

Drag testing update:

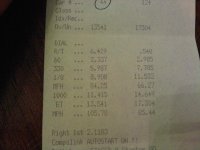

I made it to the track tonight and made 16 passes down the strip.

Best ET was 14.27 @ 102.39 MPH

60' - 2.356

330 - 6.392

1/8 - 9.458 @ 80.8 MPH

1000 - 12.069

ET - 14.270

MPH - 102.39

According to the CompD HP calculator, the best MPH with stock WH1C (HX-35) calculates to 382 rwhp.

According to the CompD HP calculator, the best MPH with GT4294 calculates to 400 rwhp or a gain of 18 HP. This is with identical fueling setup, zero changes.

Pulling up historical weather data from June 16th when I made the best stock turbo run, weather was 88*F, 29.61 barometer, 4% humidity, for a calculated density altitude of 4692 ft.

Tonight during the best run, the weather was 80.1*F, 29.54 barometer, 18% humidity for a calculated DA of 4351 ft.

If you factor in the weather difference, the GT4294 added 17 horsepower vs the stock turbo.

In closer comparison of my 13.68 run vs GT4294 14.27:

Difference at 330 ft .584

Difference in ET .582

The reason the GT4294 is slower is it takes longer to reach full boost.

In the Junker's current setup, there isn't enough traction to hold a 4-5psi boosted launch. When I left at 2-3 psi, it would bog and not spool till 2nd gear. If I left at 4-5psi, it would shake the tires and I'd have to pedal it to regain traction which would snuff out the turbo.

If the Junker had full blown race slicks and good enough track prep to hold a 10 psi launch, I really think it would run quicker with this turbo, somewhere in the 13.2 to 13.0 range.

Huge thanks to Phil Taylor at Diesel Performance Converters for the current torque converter. I removed the off-brand triple disk that was too tight to spool-up and replaced it with this converter from Phil. The converter daily drives almost identical to the older tight one except for at idle where it pushes the truck a little less and on the top end where it lets the truck turn about 200 more rpm.

It's amazing, when I'm at the line, it stalls right at 1700 rpm, and as I keep holding it, the rpm's slowly rise to 1800, 1900, and after about 5-6 seconds it hits 2300 where the turbo comes to life and really starts building boost. If I stay in it, it will make about 10 psi at 2400 rpm before it blows through the brakes.

Thanks Phil, awesome converter!

I made it to the track tonight and made 16 passes down the strip.

Best ET was 14.27 @ 102.39 MPH

60' - 2.356

330 - 6.392

1/8 - 9.458 @ 80.8 MPH

1000 - 12.069

ET - 14.270

MPH - 102.39

According to the CompD HP calculator, the best MPH with stock WH1C (HX-35) calculates to 382 rwhp.

According to the CompD HP calculator, the best MPH with GT4294 calculates to 400 rwhp or a gain of 18 HP. This is with identical fueling setup, zero changes.

Pulling up historical weather data from June 16th when I made the best stock turbo run, weather was 88*F, 29.61 barometer, 4% humidity, for a calculated density altitude of 4692 ft.

Tonight during the best run, the weather was 80.1*F, 29.54 barometer, 18% humidity for a calculated DA of 4351 ft.

If you factor in the weather difference, the GT4294 added 17 horsepower vs the stock turbo.

In closer comparison of my 13.68 run vs GT4294 14.27:

Difference at 330 ft .584

Difference in ET .582

The reason the GT4294 is slower is it takes longer to reach full boost.

In the Junker's current setup, there isn't enough traction to hold a 4-5psi boosted launch. When I left at 2-3 psi, it would bog and not spool till 2nd gear. If I left at 4-5psi, it would shake the tires and I'd have to pedal it to regain traction which would snuff out the turbo.

If the Junker had full blown race slicks and good enough track prep to hold a 10 psi launch, I really think it would run quicker with this turbo, somewhere in the 13.2 to 13.0 range.

Huge thanks to Phil Taylor at Diesel Performance Converters for the current torque converter. I removed the off-brand triple disk that was too tight to spool-up and replaced it with this converter from Phil. The converter daily drives almost identical to the older tight one except for at idle where it pushes the truck a little less and on the top end where it lets the truck turn about 200 more rpm.

It's amazing, when I'm at the line, it stalls right at 1700 rpm, and as I keep holding it, the rpm's slowly rise to 1800, 1900, and after about 5-6 seconds it hits 2300 where the turbo comes to life and really starts building boost. If I stay in it, it will make about 10 psi at 2400 rpm before it blows through the brakes.

Thanks Phil, awesome converter!