You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ahale's 94 Build thread

- Thread starter ahale2772

- Start date

ahale2772

New member

- Joined

- Oct 27, 2011

- Messages

- 2,442

new clutch is in, so far its OK. Pedal engagement is crazy light, twice as light as the stock clutch. make it kind of weird to drive. But, other than it being a bit grabby i like it.

now that I can finally get a good pull in the truck its brutally obvious that I need more fuel. Truck pulls hard enough to spin duallys in third or fourth, but falls on its face around 3000rpm. once the turbo spools its clear as day.

waiting to get paid from some Bonehead i sold a D80 axle t0, once my play money fund gets a bit of a refill I'll be ordering a turbo. I'll rig up a fuel system once the weather gets nice this week

brought home a new project this morning, 2wd Dually 89' thats getting a ppump 12V and an AT545

now that I can finally get a good pull in the truck its brutally obvious that I need more fuel. Truck pulls hard enough to spin duallys in third or fourth, but falls on its face around 3000rpm. once the turbo spools its clear as day.

waiting to get paid from some Bonehead i sold a D80 axle t0, once my play money fund gets a bit of a refill I'll be ordering a turbo. I'll rig up a fuel system once the weather gets nice this week

brought home a new project this morning, 2wd Dually 89' thats getting a ppump 12V and an AT545

ahale2772

New member

- Joined

- Oct 27, 2011

- Messages

- 2,442

fuel system = made.

most of it is 5/8 airbrakes line. Got a sump from a buddy (1tgenctd) and threw that on, amazingly its not leaking, IDK how. Mounted two filters just behind the cab on the outside of the frame, driver side. One is a primary water separator and one is a 10 micron.

hogged out the outlet of the stock piston pump to 3/8 npt, and made a fitting for the inlet of the pump to adapt to 3/8 npt. then made a fitting for the stock return banjo similar to what airdog supplies in their kits.

Very first ride the sump sucked up a plastic plug that must have been floating around in the bottom of the tank. flat towed it home about a mile and pulled the sump. after re-assembling it I took it for a ride and the system is not working as it should. I need to throw a gauge on it, but as of now the truck has less power than it did before.

two possible issues... the lift pump could be a low pressure pump (I swapped from my stock lift pump to one that came off a spare motor).... I dont know why it would be a low pressure pump... but clearly I need to throw a guage on and check.

oorrrr.... the filters could be plugged. the filter head i'm using came off my 89 and I had a steel tank mounted in the bed that had some **** in it. Never changed them because the filter head was only on for about 300 miles before the truck got parted out. I'll change them for good measure first thing in the morning.

I dont know if my big line/stock pump setup is going to work, but there is a dyno I'd like to go to in about a week, I hope I get it dialed in. I'll throw up some pics of my setup tomorrow when the big ball of fire in the sky comes out.

most of it is 5/8 airbrakes line. Got a sump from a buddy (1tgenctd) and threw that on, amazingly its not leaking, IDK how. Mounted two filters just behind the cab on the outside of the frame, driver side. One is a primary water separator and one is a 10 micron.

hogged out the outlet of the stock piston pump to 3/8 npt, and made a fitting for the inlet of the pump to adapt to 3/8 npt. then made a fitting for the stock return banjo similar to what airdog supplies in their kits.

Very first ride the sump sucked up a plastic plug that must have been floating around in the bottom of the tank. flat towed it home about a mile and pulled the sump. after re-assembling it I took it for a ride and the system is not working as it should. I need to throw a gauge on it, but as of now the truck has less power than it did before.

two possible issues... the lift pump could be a low pressure pump (I swapped from my stock lift pump to one that came off a spare motor).... I dont know why it would be a low pressure pump... but clearly I need to throw a guage on and check.

oorrrr.... the filters could be plugged. the filter head i'm using came off my 89 and I had a steel tank mounted in the bed that had some **** in it. Never changed them because the filter head was only on for about 300 miles before the truck got parted out. I'll change them for good measure first thing in the morning.

I dont know if my big line/stock pump setup is going to work, but there is a dyno I'd like to go to in about a week, I hope I get it dialed in. I'll throw up some pics of my setup tomorrow when the big ball of fire in the sky comes out.

ahale2772

New member

- Joined

- Oct 27, 2011

- Messages

- 2,442

Fuel system is fixed...

first i made a fitting off the front of the pump for fuel pressure, off the allen plug that people use to dual feed trucks. I welded a male #4 fitting on the end. fuel pressure was instantly down to 0 with any load on the truck.

then took and changed the filters, the primary was full of rust, but it didn't make the truck run any better

then went and put 120$ of fuel in the tank, thinking the 4 gal I had in the tank was probably flowing to the back of the tank... no dice there either.

....then I threw a spare FASS pump on the truck from a VP44 truck, the type with no fuel filters.

still ran like garbage.

finally pulled the piston lift pump off again and realized that I tapped the check valve on the outlet of the pump on too far. Looking at the checkvalve and the way the outlet is setup one would imagine that it pressed all the way in.... nope.

anyway... now ive got about 65psi of pressure revving the truck in neutral, and 25 psi full bore with the dually's spinning in 4th

my biggest question is now... why the hell is the truck still clearing up all the fuel?

so I'm at 45pi of inlet fuel pressure normally, the afc is tuned for full travel, and slid all the way forward. its got a rack plug, no plate, 4k's set at about 4 clicks, and 5x16's.

air side is a steed comp, and the 62/68/.84 T4

I feel like there is more fuel there than what this little 62 is burning....

dynoing this saturday, hoping for 525 or better.

first i made a fitting off the front of the pump for fuel pressure, off the allen plug that people use to dual feed trucks. I welded a male #4 fitting on the end. fuel pressure was instantly down to 0 with any load on the truck.

then took and changed the filters, the primary was full of rust, but it didn't make the truck run any better

then went and put 120$ of fuel in the tank, thinking the 4 gal I had in the tank was probably flowing to the back of the tank... no dice there either.

....then I threw a spare FASS pump on the truck from a VP44 truck, the type with no fuel filters.

still ran like garbage.

finally pulled the piston lift pump off again and realized that I tapped the check valve on the outlet of the pump on too far. Looking at the checkvalve and the way the outlet is setup one would imagine that it pressed all the way in.... nope.

anyway... now ive got about 65psi of pressure revving the truck in neutral, and 25 psi full bore with the dually's spinning in 4th

my biggest question is now... why the hell is the truck still clearing up all the fuel?

so I'm at 45pi of inlet fuel pressure normally, the afc is tuned for full travel, and slid all the way forward. its got a rack plug, no plate, 4k's set at about 4 clicks, and 5x16's.

air side is a steed comp, and the 62/68/.84 T4

I feel like there is more fuel there than what this little 62 is burning....

dynoing this saturday, hoping for 525 or better.

ChuMaDD

Meh

- Joined

- Aug 6, 2012

- Messages

- 613

Sweet, I have a slightly similar build (except I bought a 64 instead of 62) that I will be starting as soon as the parts get here. So I hope for some of the same results

Maybe the DV's are in need of an upgrade now for increased fueling unless I missed that you already did that somewhere

Maybe the DV's are in need of an upgrade now for increased fueling unless I missed that you already did that somewhere

NickTF

Single turbo turd.

- Joined

- Jun 4, 2007

- Messages

- 5,887

20 degrees, rechecked the other day.

The truck gets out of its own way, i think it will be mid 5's

Either i really need to pump more fuel into this 160. Pump or this is the little 62 that could

I wouldn't be surprised. I'm running the same charger and have been super lazy with it given plans kind of slowed down for the truck but I could see the same for my setup with some tuning.

ahale2772

New member

- Joined

- Oct 27, 2011

- Messages

- 2,442

well racking the barrels made it fuel like it should, took 15minutes.

now spinning tire in 3rd and 4th is just laying on the pedal, where as before it had to be perfect conditions. the butt dyno feels good. smoke is now a constant dark haze

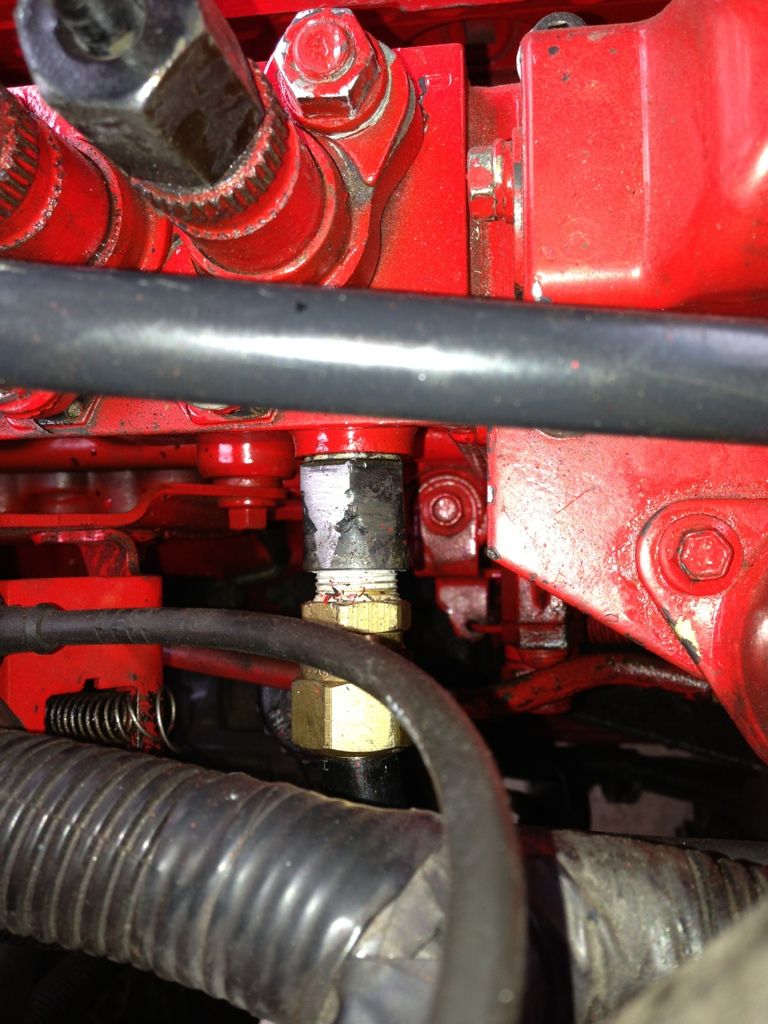

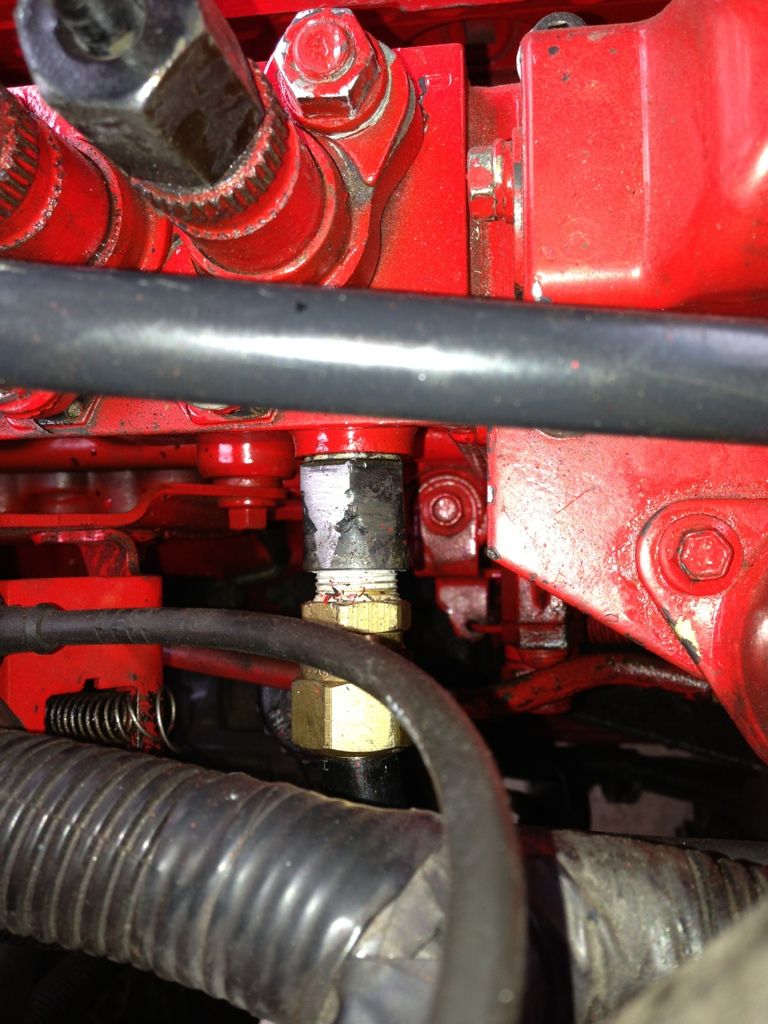

some pics of what ive been doing finally

filter setup and sump

the loudest FASS pump on the face of the planet Edit: can these be turned up? guessing there is an allen at the bottom of the hole on the front of the pump?

inlet fitting is a stock fitting drilled and welded with a 3/8 pipe female adaptor

the test port fitting

barrels racked.... no more pretty paint LOL

now spinning tire in 3rd and 4th is just laying on the pedal, where as before it had to be perfect conditions. the butt dyno feels good. smoke is now a constant dark haze

some pics of what ive been doing finally

filter setup and sump

the loudest FASS pump on the face of the planet Edit: can these be turned up? guessing there is an allen at the bottom of the hole on the front of the pump?

inlet fitting is a stock fitting drilled and welded with a 3/8 pipe female adaptor

the test port fitting

barrels racked.... no more pretty paint LOL

Last edited:

FASSAshley

Comp Diesel Sponsor

- Joined

- May 12, 2010

- Messages

- 50

The pump could be getting loud because you don't have the Weep hole facing towards the ground and if the oil seal fails then the pump will fill with fuel and stop working. What pressure are you looking for?

Russellt198

New member

- Joined

- Nov 1, 2011

- Messages

- 68

That sump is some pretty. Might have to bite the bullet and do one. Did you drop tank?

ahale2772

New member

- Joined

- Oct 27, 2011

- Messages

- 2,442

The pump could be getting loud because you don't have the Weep hole facing towards the ground and if the oil seal fails then the pump will fill with fuel and stop working. What pressure are you looking for?

that hole on the front is intended to be facing down?

I just didnt know if there was a way to get anymore psi out of it, more is better for me

didnt drop the tank Rusty, just drilled and cleaned out the shavings, if I missed anything it will get sucked into the primary filter

YOUNG GUNS15

Im AWESOME!!!!

- Joined

- Sep 24, 2009

- Messages

- 7,346

5k's went in today, improved fueling

Who's springs?

ahale2772

New member

- Joined

- Oct 27, 2011

- Messages

- 2,442

Scheid's 5k's

Dyno'd today. 511/920 with a .95 correction factor

Dyno seemed low, a tuned/intake exhaust 6.4 only put down 499hp. But, the graph showed peak power at 3000 rpm, compared to peak at 2700 before.

Im happy with it, the combo of 5k's the fuel system and racking the barrels makes the 62 unable to clean up the fuel.

Ordered a s468 yesterday

Dyno'd today. 511/920 with a .95 correction factor

Dyno seemed low, a tuned/intake exhaust 6.4 only put down 499hp. But, the graph showed peak power at 3000 rpm, compared to peak at 2700 before.

Im happy with it, the combo of 5k's the fuel system and racking the barrels makes the 62 unable to clean up the fuel.

Ordered a s468 yesterday

tatersalad

New member

- Joined

- Jul 26, 2009

- Messages

- 506

now watcha gna do with that 62????

ahale2772

New member

- Joined

- Oct 27, 2011

- Messages

- 2,442

The truck on the dyno, some nice duramax's showed up yesterday, i think i was the only 12v out of the 400's

Thats tim judd strapping the truck down, he was in the DCP this year, Joel saunders was around as well, he had a 3rdgen at 950+ hp in the dcp a few years back.

Thats tim judd strapping the truck down, he was in the DCP this year, Joel saunders was around as well, he had a 3rdgen at 950+ hp in the dcp a few years back.

YOUNG GUNS15

Im AWESOME!!!!

- Joined

- Sep 24, 2009

- Messages

- 7,346

Your getting the turbo I should have bought months ago....